Flame-retardant and tear-resistant silicon rubber and preparation method thereof

A technology for tear-resistant silicone rubber and silicone rubber, applied in the field of silicone rubber, can solve the problems of restricting the application of silicone rubber products, reducing the mechanical properties of silicone rubber, and general compatibility of silicone rubber, achieving excellent electrical insulation performance, increasing phase Capacitive, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A flame-retardant and tear-resistant silicone rubber, comprising the following components in parts by weight: 100 parts of silicone rubber; 2 parts of hydroxy silicone oil; 2 parts of siloxane; 20 parts of wollastonite whiskers; 20 parts of mica powder; 0.5 parts; 0.5 parts of vulcanizing agent; 0.1 parts of coupling agent.

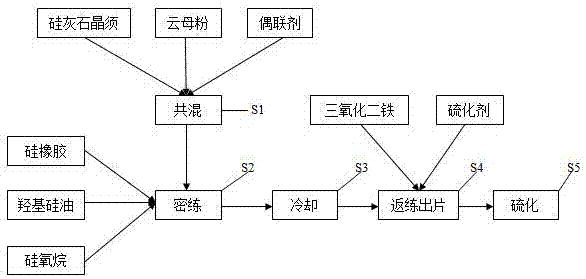

[0026] A preparation method of flame-retardant and tear-resistant silicone rubber, comprising the following steps:

[0027] (1) blending the wollastonite whiskers, mica powder and coupling agent in the above parts by weight, and performing surface active treatment;

[0028] (2) Then the above weight parts of silicone rubber, hydroxy silicone oil, siloxane, and the above-mentioned treated powder fillers are mixed together, the mixing temperature is 140-150°C, the mixing time is 120-150 minutes, and the mixing and kneading is completed Afterwards, carry out vacuum treatment;

[0029] (3) Cool down to 90-110°C through cooling water in the jacket of ...

Embodiment 2

[0033] A flame-retardant and tear-resistant silicone rubber, comprising the following components in parts by weight: 110 parts of silicone rubber; 4 parts of hydroxy silicone oil; 3 parts of siloxane; 30 parts of wollastonite whiskers; 40 parts of mica powder; 1.5 parts; vulcanizing agent 1.5 parts; coupling agent 0.4 parts;

[0034] A preparation method of flame-retardant and tear-resistant silicone rubber, comprising the following steps:

[0035] (1) blending the wollastonite whiskers, mica powder and coupling agent in the above parts by weight, and performing surface active treatment;

[0036] (2) Then the above weight parts of silicone rubber, hydroxy silicone oil, siloxane, and the above-mentioned treated powder fillers are mixed together, the mixing temperature is 150-160°C, the mixing time is 90-120 minutes, and the mixing and kneading is completed Afterwards, carry out vacuum treatment;

[0037] (3) Cool down to 90-110°C through cooling water in the jacket of the int...

Embodiment 3

[0041] A flame-retardant and tear-resistant silicone rubber, comprising the following components in parts by weight: 120 parts of silicone rubber; 5 parts of hydroxy silicone oil; 5 parts of siloxane; 50 parts of wollastonite whiskers; 50 parts of mica powder; 2 parts; 2 parts of vulcanizing agent; 0.5 parts of coupling agent;

[0042] A preparation method of flame-retardant and tear-resistant silicone rubber, comprising the following steps:

[0043] (1) blending the wollastonite whiskers, mica powder and coupling agent in the above parts by weight, and performing surface active treatment;

[0044] (2) Then the above weight parts of silicone rubber, hydroxy silicone oil, siloxane, and the above-mentioned processed powder fillers are mixed together, the mixing temperature is 160-170°C, the mixing time is 60-90 minutes, and the mixing and kneading is over Afterwards, carry out vacuum treatment;

[0045] (3) Cool down to 90-110°C through cooling water in the jacket of the inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com