Ethylene-propylene-diene monomer flame-retardant rubber and production method thereof

A technology of EPDM rubber and flame-retardant rubber, which is applied in the field of flame-retardant rubber, can solve the problems of high price, general flame-retardant effect, and small addition of halogen flame retardants, and achieve reduced production costs and excellent wear resistance , good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

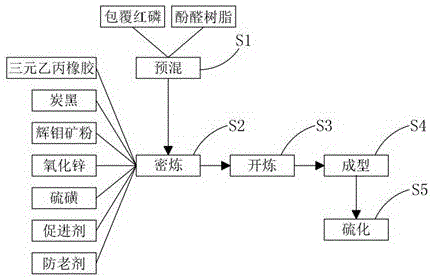

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0021] The EPDM flame-retardant rubber includes 120 parts by weight of EPDM rubber, 60 parts by weight of carbon black, 15 parts by weight of coated red phosphorus, 30 parts by weight of phenolic resin, and 5 parts by weight of zinc oxide , 30 parts by weight of molybdenite powder, 2 parts by weight of sulfur, 1 part by weight of accelerator, and 1 part by weight of anti-aging agent.

[0022] The production method of described EPDM flame retardant rubber may further comprise the steps:

[0023] S1: premixing: premixing 15 parts by weight of the coated red phosphorus and 30 parts by weight of the phenolic resin, so that the coated red phosphorus is fully dispersed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com