Fire-proof rubber material for air spring and preparation method thereof, air spring and preparation method thereof

A technology of rubber materials and air springs, applied in the field of polymer materials, can solve problems such as delamination and cracking of substrates, achieve low cost, simple method, and reduce smoke density and smoke toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

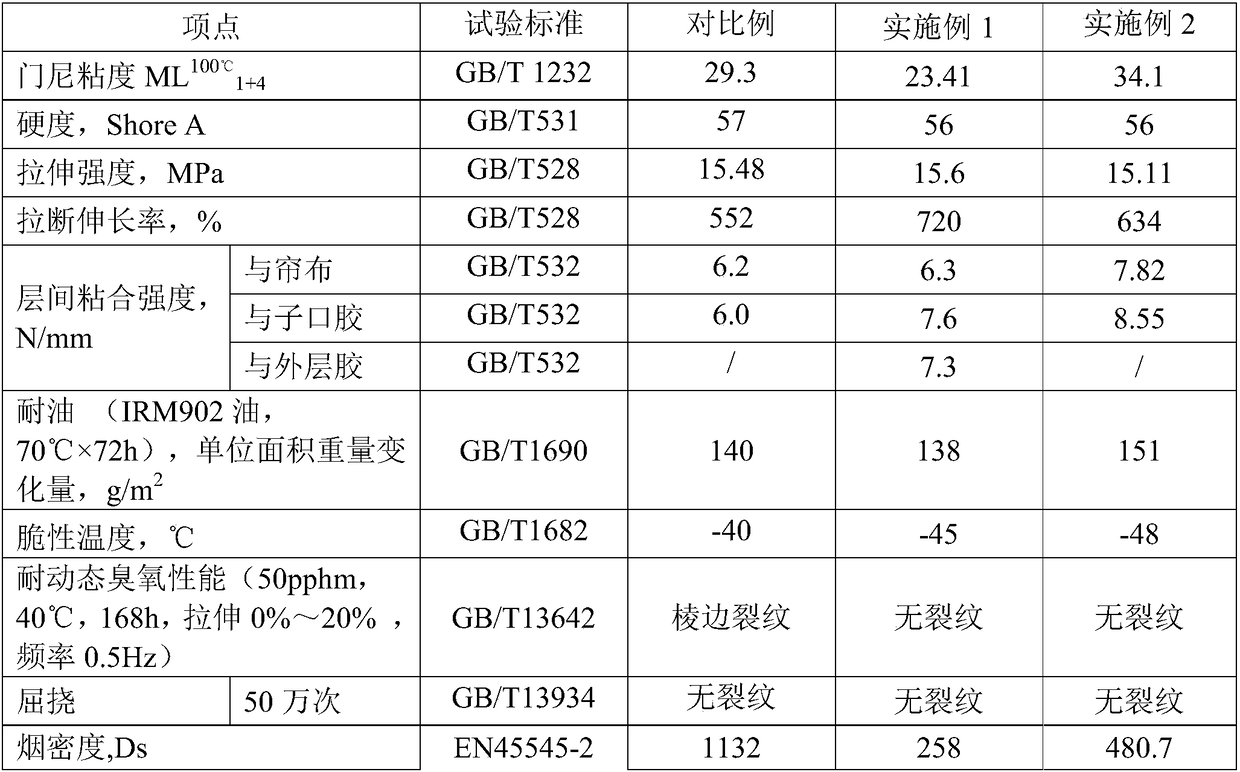

Examples

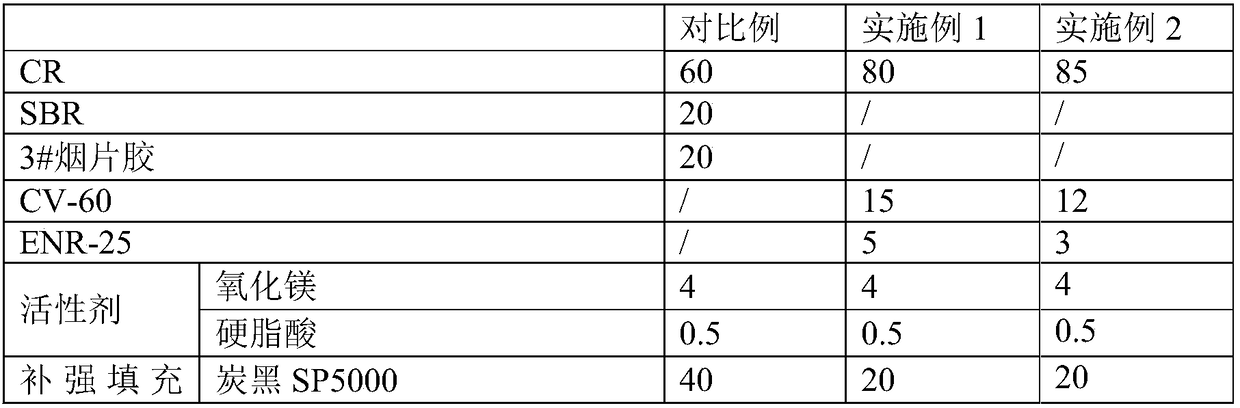

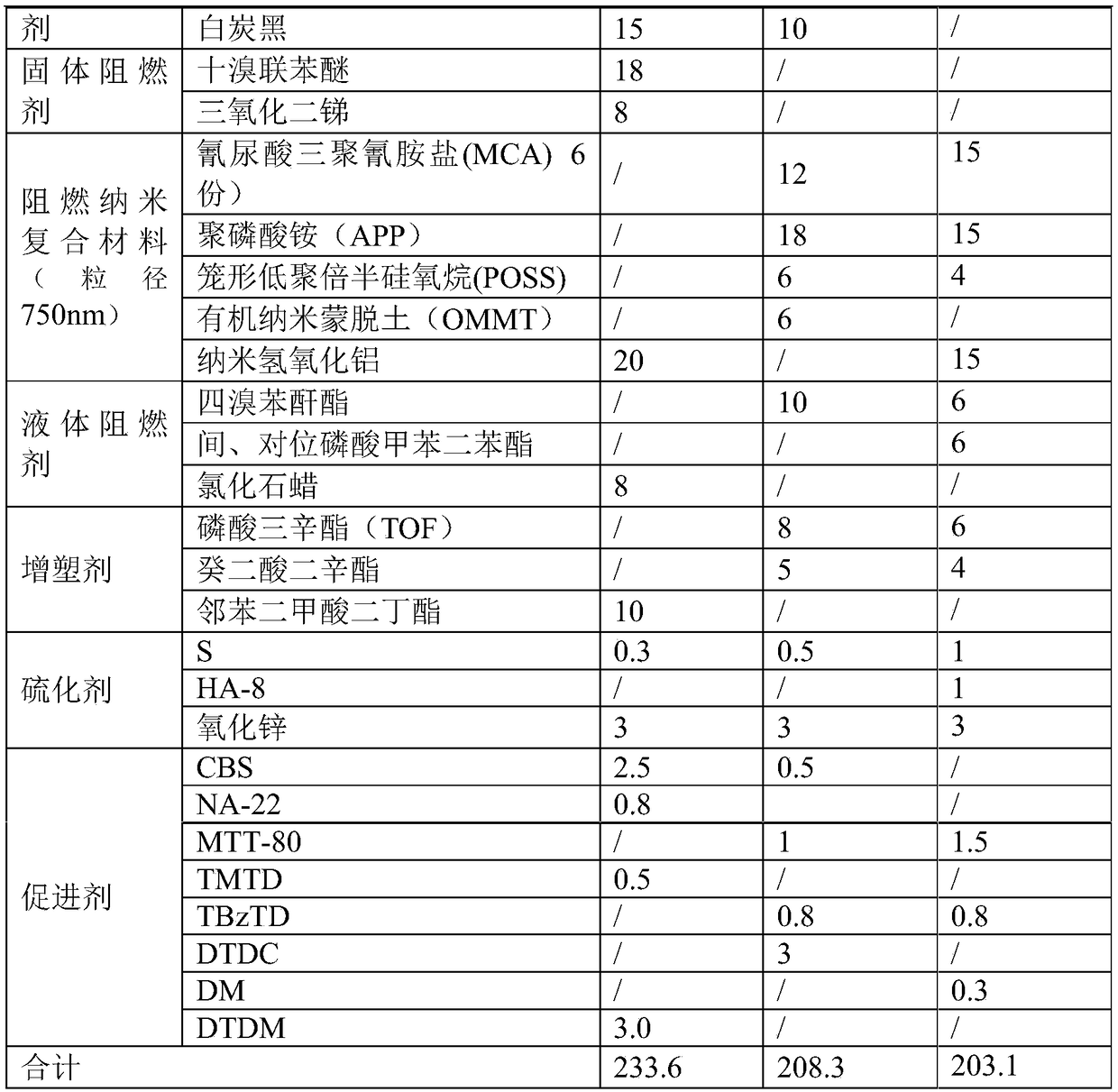

Embodiment 1

[0047] The preparation method of the air spring in the present embodiment comprises the following steps:

[0048] (1) Add chloroprene rubber, general-purpose solid natural rubber and epoxidized natural rubber into the internal mixer and mix evenly, and the mixing temperature is controlled at 40-80°C; then add magnesium oxide and stearic acid, and mix for 3 Minutes; then add carbon black SP5000, white carbon black, flame retardant nanocomposite (a mixture of melamine cyanurate, ammonium polyphosphate, cage oligosilsesquioxane and organic nano-montmorillonite), tetrabromophthalic anhydride , plasticizer (trioctyl phosphate and dioctyl sebacate) were mixed for 8 minutes, and the mixing temperature was controlled at 70-115°C; then the mixed rubber was cooled to below 60°C, and the vulcanizing agent, accelerator Put the agent together in the internal mixer and knead. When the temperature of the rubber material reaches 95°C or more, the glue is discharged, and the fireproof rubber m...

Embodiment 2

[0051] The preparation method of the air spring in the present embodiment comprises the following steps:

[0052] (1) Add chloroprene rubber, general-purpose solid natural rubber and epoxidized natural rubber into an internal mixer and mix evenly, and the mixing temperature is controlled at 40-80°C; then add magnesium oxide and stearic acid for 3 minutes of mixing ; Then add carbon black SP5000, flame retardant nanocomposite material (the mixture of melamine cyanurate, ammonium polyphosphate, cage oligosilsesquioxane and nano aluminum hydroxide), tetrabromophthalic anhydride ester, plasticizer (phosphoric acid Trioctyl ester and dioctyl sebacate) were mixed for 8 minutes, and the mixing temperature was controlled at 70-115°C; then the mixed rubber was cooled to below 60°C, and the vulcanizing agent and accelerator were added to the internal mixer together Medium mixing, when the temperature of the rubber material reaches above 95°C, the rubber is discharged, and the fireproof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com