Hyperbranched polyurethane finishing coat for urban railway vehicles

A technology for hyperbranched polyurethane and urban rail vehicles, which is applied in the field of hyperbranched polyurethane topcoat for urban rail vehicles and its preparation, can solve the problems of increased color difference and reduced gloss of the coating, and achieves improved smoothness and weather resistance, The effect of maintaining gloss and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A hyperbranched polyurethane topcoat for urban rail vehicles, comprising two parts of a paint material and a curing agent, characterized in that said polyurethane paint is made from the following raw materials and steps:

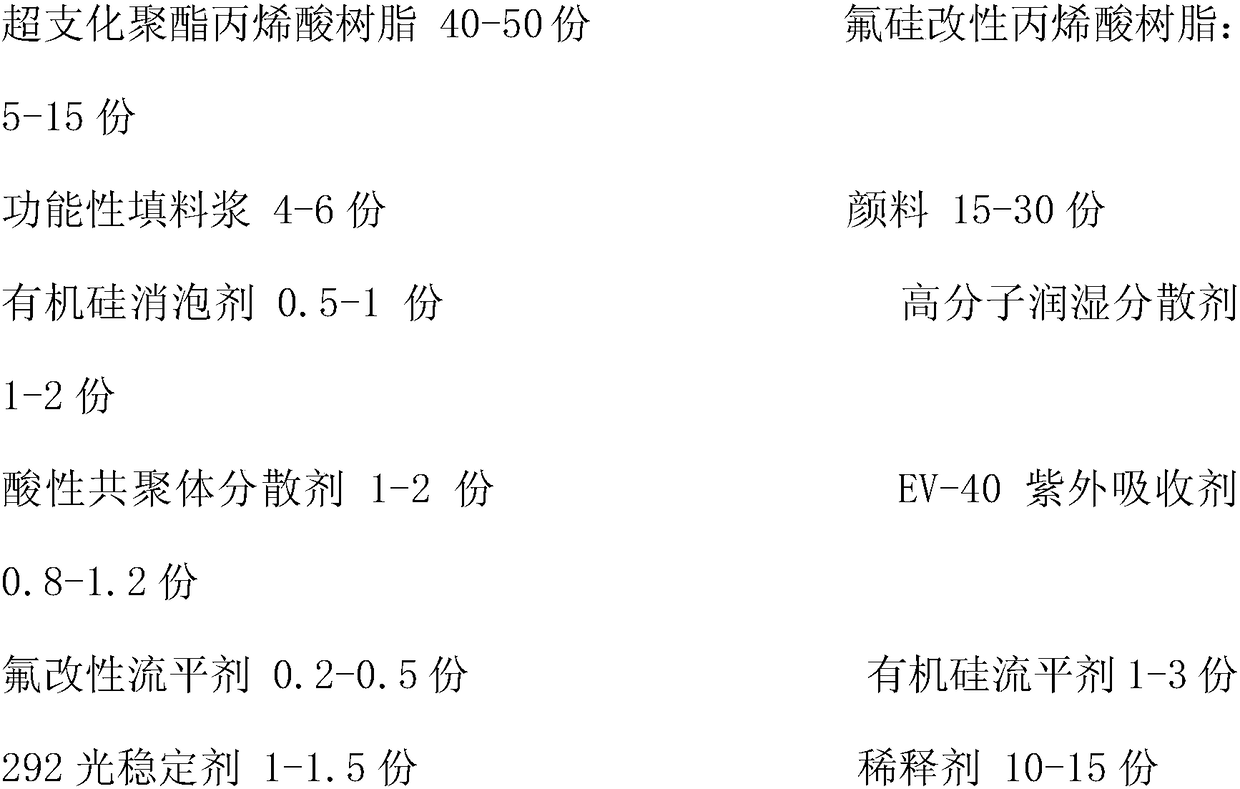

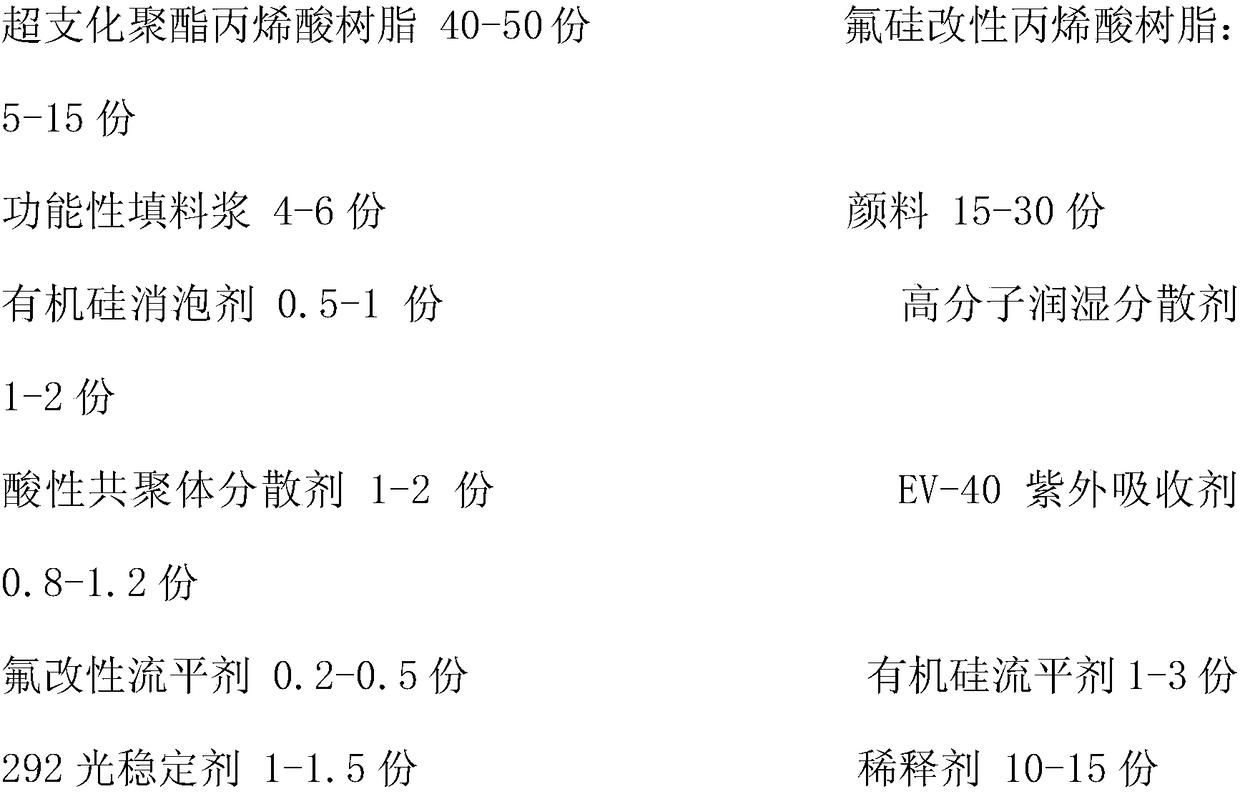

[0051] (1) The weight ratio of each raw material forming the paint is:

[0052]

[0053] Wherein the diluent is xylene: butyl acetate: a mixed solvent of PMA=1:1:1;

[0054] The functional filler slurry is nanocrystalline carbon powder: nano-dispersant: hyperbranched polyester acrylic resin: diluent=50:5:40:5;

[0055] (2) The weight proportion of each raw material forming curing agent is:

[0056] 45-55 parts of isophorone diisocyanate (IPDI),

[0057] 20-25 parts of xylene,

[0058] 20-25 parts of butyl acetate;

[0059] The steps are:

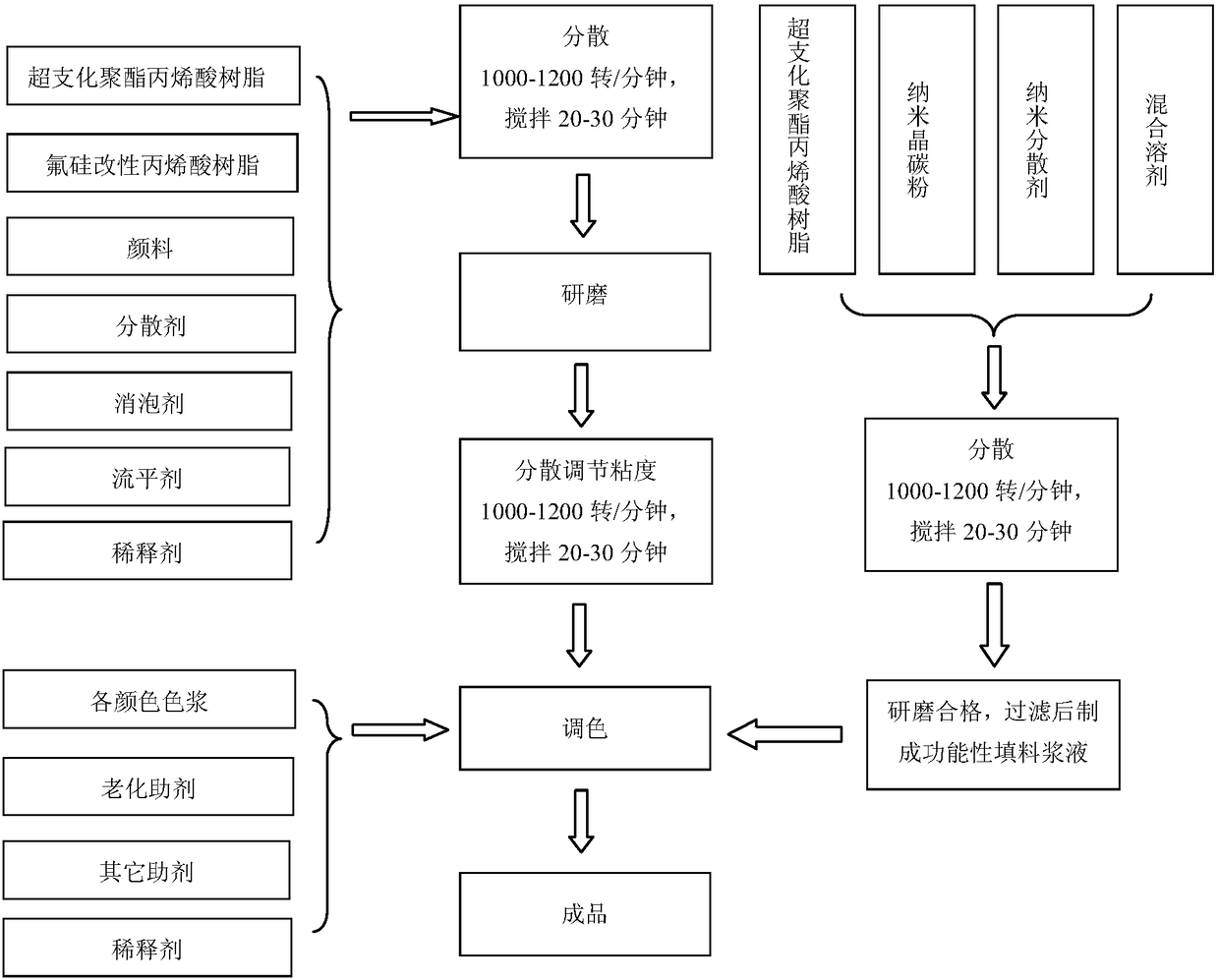

[0060] A. Preparation of functional filler slurry: first add hyperbranched polyester acrylic resin in the container by weight, and place the container cylinder under the disperser, turn on the disperser, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com