High-reflection thermal insulation coating

A heat-insulating coating and high-reflection technology, which is applied in the direction of reflection/signal coating, anti-fouling/underwater coating, coating, etc., can solve the problems of weak reflection ability of nano-scale visible light and infrared light, weak reflection ability of infrared light, etc. Achieve excellent color and gloss retention, smooth feel, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

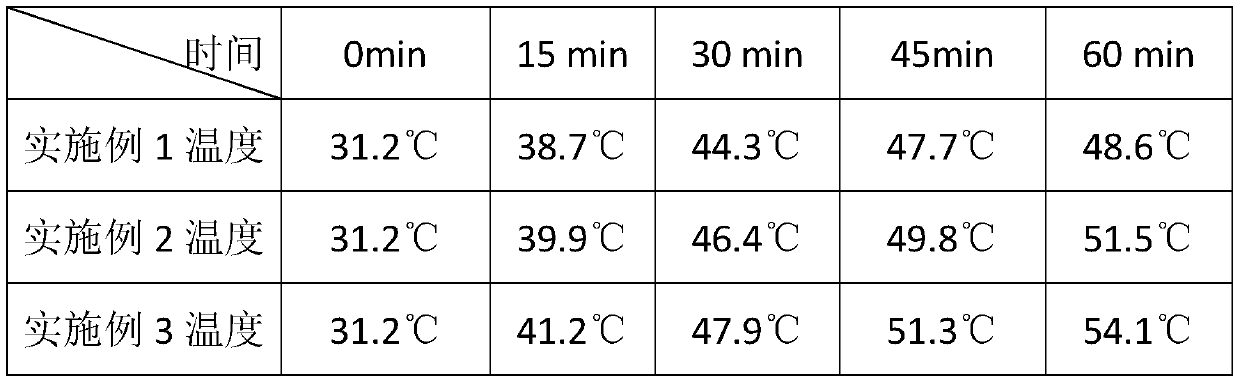

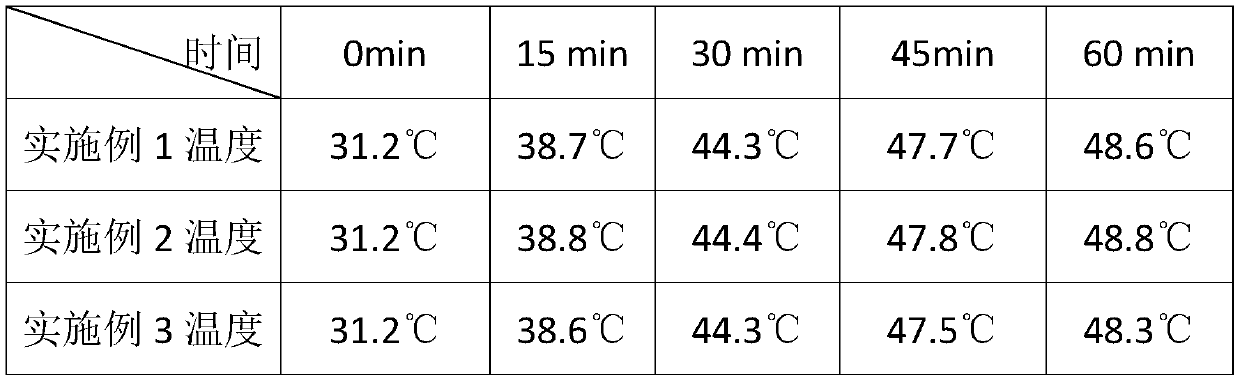

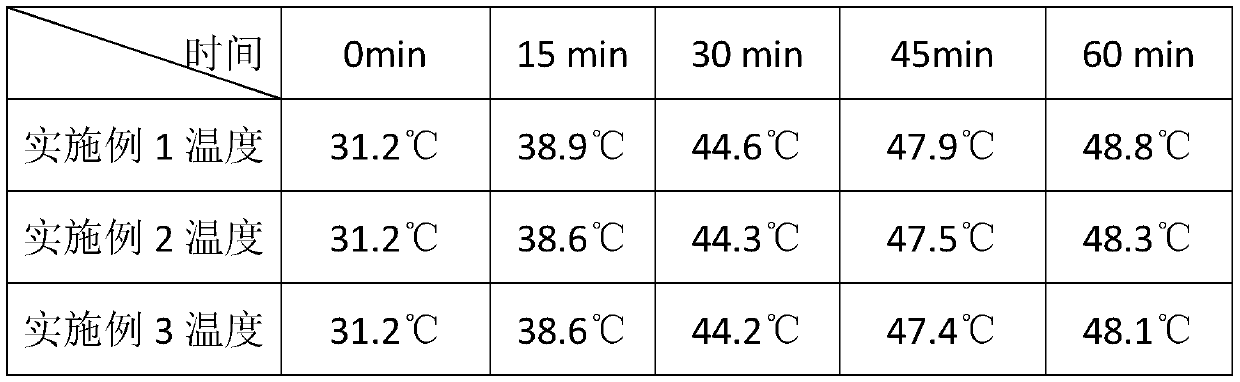

Embodiment 1

[0027] The present embodiment comprises a primer layer and a topcoat layer, and the primer layer is made up of the following components (parts by weight): the proportions by mass of each raw material of the primer layer are: average particle diameter 300nm rutile titanium dioxide 13%, 16% of hollow glass microspheres with an average particle size of 300nm, 7% of talcum powder with an average particle size of 200nm, 1% of ferric chloride, 46% of organosilicon-modified acrylic acid, and 17% of purified water.

[0028] The parts by mass of the raw materials of the topcoat layer are: 5% of kaolin with an average particle size of 10 μm, 10% of rutile titanium dioxide with an average particle size of 10 μm, 18% of hollow glass microspheres with an average particle size of 20 μm, and 8% of talc powder with an average particle size of 20 μm. %, ferric chloride 1%, silicone modified acrylic acid 42%, purified water 16%.

[0029] When spraying, the spraying thickness of the primer layer...

Embodiment 2

[0031] The present embodiment comprises a primer layer and a topcoat layer, and the primer layer is made up of the following components (parts by weight): the proportions by mass of each raw material of the primer layer are: average particle diameter 300nm rutile titanium dioxide 13%, 16% of hollow glass microspheres with an average particle size of 300nm, 7% of talcum powder with an average particle size of 200nm, 1% of ferric chloride, 46% of organosilicon-modified acrylic acid, and 17% of purified water.

[0032] The parts by mass of the raw materials of the topcoat layer are: 8% of kaolin with an average particle size of 10 μm, 7% of rutile titanium dioxide with an average particle size of 10 μm, 18% of hollow glass microspheres with an average particle size of 20 μm, and 8% of talc powder with an average particle size of 20 μm %, ferric chloride 1%, silicone modified acrylic acid 42%, purified water 16%.

[0033] When spraying, the spraying thickness of the primer layer i...

Embodiment 3

[0035] The present embodiment comprises a primer layer and a topcoat layer, and the primer layer is made up of the following components (parts by weight): the proportions by mass of each raw material of the primer layer are: average particle diameter 300nm rutile titanium dioxide 13%, 16% of hollow glass microspheres with an average particle size of 300nm, 7% of talcum powder with an average particle size of 200nm, 1% of ferric chloride, 46% of organosilicon-modified acrylic acid, and 17% of purified water.

[0036] The parts by mass of the raw materials of the topcoat layer are: 11% of kaolin with an average particle size of 10 μm, 4% of rutile titanium dioxide with an average particle size of 10 μm, 18% of hollow glass microspheres with an average particle size of 20 μm, and 8% of talc powder with an average particle size of 20 μm. %, ferric chloride 1%, silicone modified acrylic acid 42%, purified water 16%.

[0037] When spraying, the spraying thickness of the primer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com