High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

A flame-retardant fiber and high-strength technology, which is applied in the field of high-strength environmentally friendly flame-retardant fiberboard and its preparation, can solve the problems of increased carbon monoxide concentration, increased smoke hazards, and inability to meet processing and use requirements, so as to reduce heat release and heat release rate, reduce hygroscopicity and solubility, and reduce the effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

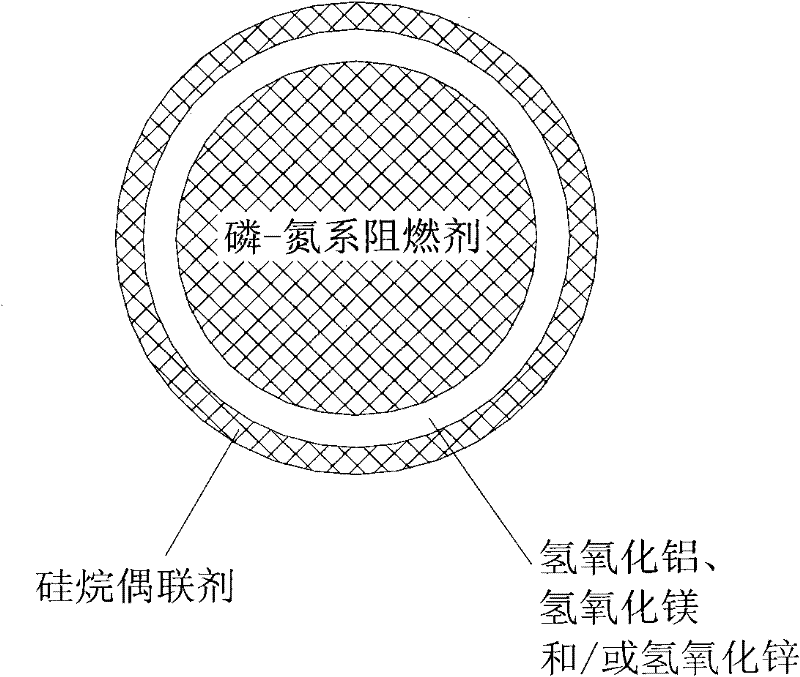

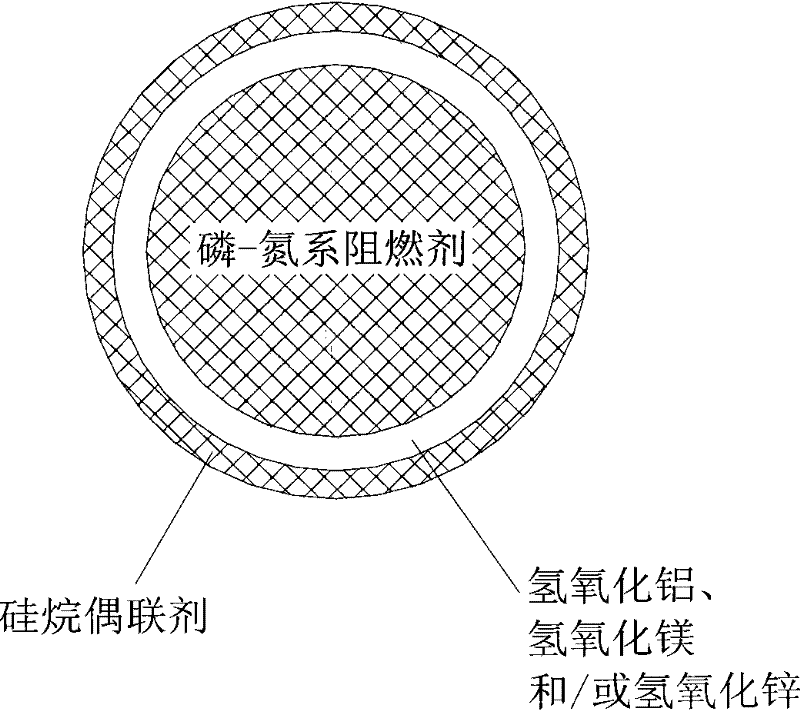

Method used

Image

Examples

Embodiment 1

[0045] A high-strength environmentally friendly flame-retardant fiberboard, which includes the following raw materials: wood fiber, flame retardant, urea-formaldehyde resin and solid paraffin; the weight ratio of the raw materials is: wood fiber: flame retardant: urea-formaldehyde resin: solid paraffin=100:3 :3:0.1.

[0046] The preparation method of the aforementioned high-strength environment-friendly flame-retardant fiberboard comprises the following steps:

[0047] 1) Preparation of flame retardant

[0048] a) adding melamine pyrophosphate to ethanol to form a suspension while stirring;

[0049] b) adding an aqueous solution of aluminum sulfate to the suspension, and keeping it at 5°C for 120 minutes to obtain a mixture A;

[0050] c) adding an aqueous ammonia solution to the mixture A and keeping it at 5° C. for 5 minutes; obtaining a mixture B;

[0051] d) Add r-aminoethyl-B-aminopropyltrimethoxysilane to the mixture B, keep it at 5°C for 120 minutes; filter to make a...

Embodiment 2

[0056] A high-strength environment-friendly flame-retardant fiberboard, which includes the following raw materials: bamboo fiber, flame retardant, melamine-modified urea-formaldehyde resin and liquid paraffin; the weight ratio of the raw materials is: bamboo fiber: flame-retardant: melamine-modified urea-formaldehyde resin: Liquid paraffin=100:30:30:4.

[0057] The preparation method of the aforementioned high-strength environment-friendly flame-retardant fiberboard comprises the following steps:

[0058] 1) Preparation of flame retardant

[0059] a) adding melamine pyrophosphate to water to form a suspension while stirring;

[0060] b) adding an aqueous solution of aluminum sulfate to the suspension, and keeping it at 5°C for 120 minutes to obtain a mixture A;

[0061] c) adding an aqueous ammonia solution to the mixture A and keeping it at 5° C. for 5 minutes; obtaining a mixture B;

[0062] d) Add r-aminoethyl-B-aminopropyltrimethoxysilane to the mixture B, keep it at 5°...

Embodiment 3

[0067] A high-strength environment-friendly flame-retardant fiberboard, which includes the following raw materials: sugarcane fiber, flame retardant, melamine-modified urea-formaldehyde resin and liquid paraffin; the weight ratio of the raw materials is: sugarcane fiber: flame retardant: melamine-modified urea-formaldehyde resin: Liquid paraffin=100:6:6:1.

[0068] The preparation method of the aforementioned high-strength environment-friendly flame-retardant fiberboard comprises the following steps:

[0069] 1) Preparation of flame retardant

[0070] a) adding melamine phosphate into toluene to form a suspension while stirring;

[0071] b) adding an aqueous solution of magnesium chloride to the suspension, and keeping it at 95° C. for 5 minutes to obtain a mixture A;

[0072] c) Add aqueous sodium hydroxide solution to mixture A, and keep it at 95° C. for 5 minutes; obtain mixture B;

[0073] d) Add r-vinyltriethoxysilane to the mixture B, keep it at 95°C for 30°C; rotary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com