Pnenolic aldehyde foam board exterior wall internal insulation system and construction method

A phenolic foam board and thermal insulation system technology, applied in thermal insulation, building components, climate change adaptation and other directions, can solve problems such as non-compliance with fire protection requirements, threatening life and property safety, general thermal insulation performance, etc., achieving good environmental protection performance and a wide range of uses , the effect of low smoke toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

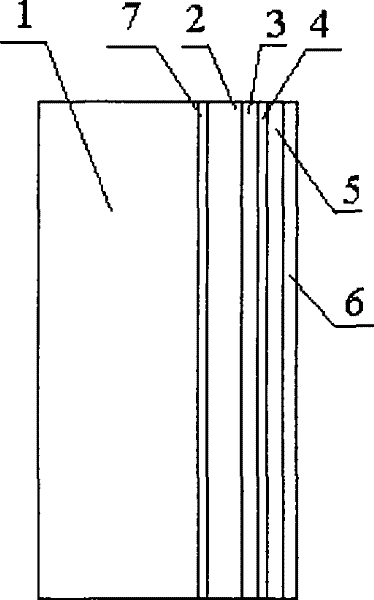

Image

Examples

Embodiment 1

[0040] (1) Preparation of whole skin phenolic foam board:

[0041] Mix the A-stage phenolic resin, surfactants, initiators and foaming agents and inject them into the mold, cure them at 80°C for 2 hours, and demold to obtain phenolic foam;

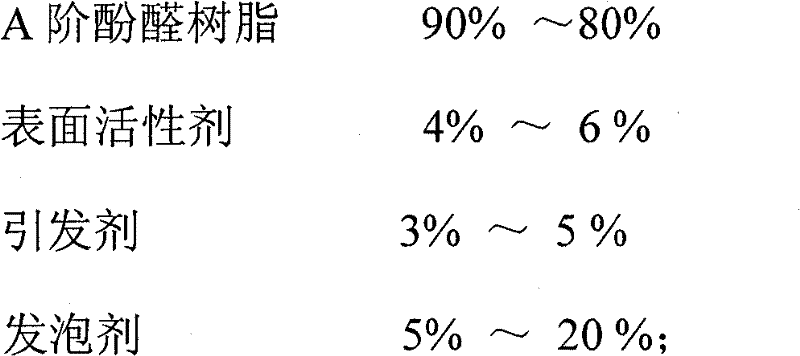

[0042] The weight percentage of each raw material is as follows:

[0043] A-stage phenolic resin 80%

[0044] Surfactant 5%

[0045] Initiator 5%

[0046] Blowing agent 10%

[0047] Use products produced by Shanghai Wangyue Engineering Material Technology Co., Ltd.;

[0048] Surfactant adopts foam stabilizer polysiloxane·polyoxyethylene-polyoxypropylene (DC-193) produced by American Air Products;

[0049] The initiator is selected from sulfuric acid with a weight concentration of 50%;

[0050] The blowing agent is selected from trichlorofluoromethane.

[0051] (2) The construction process is as follows:

[0052] (1) Make a leveling layer with a thickness of 20mm on the inner base surface of the outer wall with a flatness of less than 2mm, and then apply an...

Embodiment 2

[0065] 1) Preparation of whole skin phenolic foam board:

[0066] Mix the A-stage phenolic resin, surfactant, initiator and foaming agent and inject them into the mold, cure and mold at 90°C for 0.5 hours, demold, and obtain phenolic foam;

[0067] The weight percentage of each raw material is as follows:

[0068] A-stage phenolic resin 86%

[0069] Surfactant 3%

[0070] Initiator 3%

[0071] Foaming agent 8%

[0072] A-stage phenolic resin adopts products produced by Shanghai Wangyue Engineering Materials Technology Co., Ltd.;

[0073] Surfactant adopts foam stabilizer polysiloxane·polyoxyethylene-polyoxypropylene (DC-193) produced by American Air Products;

[0074] The initiator is selected from p-toluenesulfonic acid;

[0075] The blowing agent is selected from pentane;

[0076] (2) The construction process is as follows:

[0077] (1) Make a leveling layer with a thickness of 10mm on the inner base wall of the outer wall with a flatness lower than 2mm, and then apply an adhesive with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com