Phosphorus-containing polyether plasticizer and flame-retardant single-component silane modified sealant, and preparation methods and application thereof

A technology of silane modification and silane modified resin, which is applied in the field of sealants, can solve the problems of poor compatibility between plasticizers and silane modified resins, achieve reduced smoke density and smoke toxicity, low production cost, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

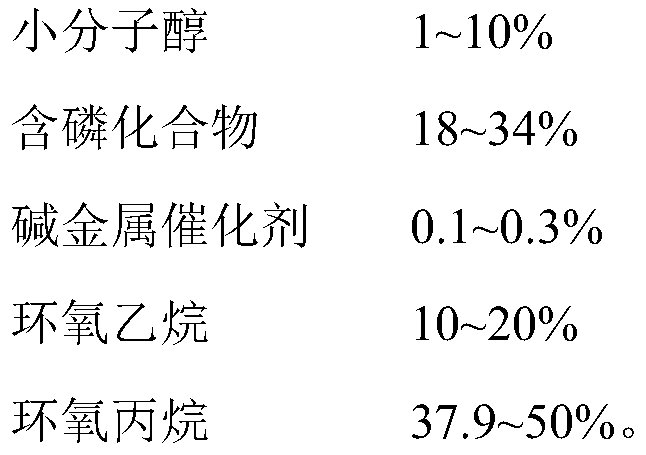

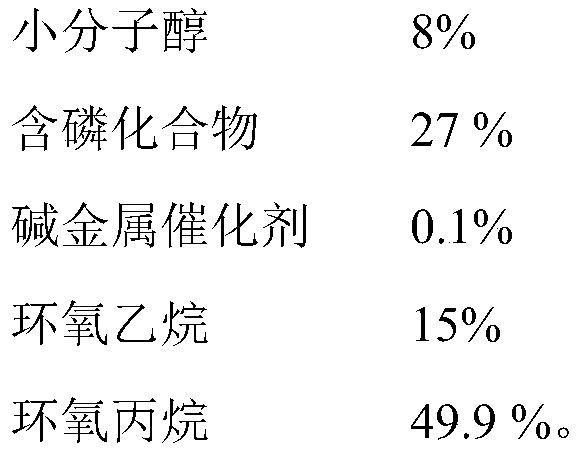

[0072] This example provides a series of phosphorus-containing polyether plasticizers, the formula and preparation method of which are as follows.

[0073] Table 1 Phosphorus-containing polyether plasticizer formula

[0074]

[0075] The preparation method is as follows:

[0076] (1) Slowly add the small molecule alcohol dropwise into the reaction vessel containing the phosphorus-containing compound under ice-salt bath conditions and stir for 3 hours, then gradually heat up to 80° C. for 3.5 to 4 hours under the protection of nitrogen (specifically, the formula in Example 1 The reaction time is 3.5h, and the reaction time of the remaining examples is 4h), the temperature is raised to 125°C for evacuation and aging for 2.5h, and the initiator is obtained when the water content is less than or equal to 200ppm;

[0077] (2) Under the protection of nitrogen, add an alkali metal catalyst into the initiator, and add propylene oxide and ethylene oxide in turn, and react at a temp...

Embodiment 6~16

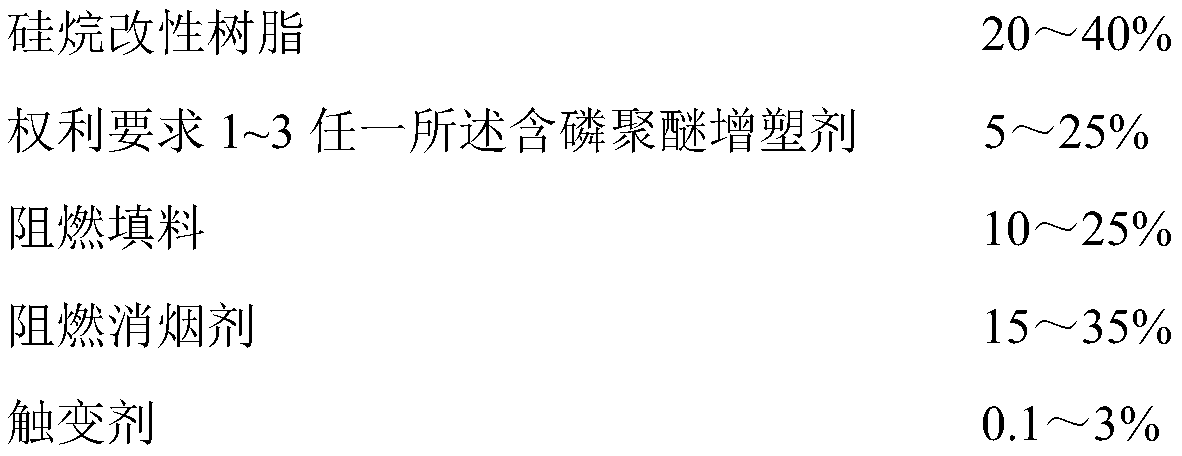

[0082] This example provides a series of flame-retardant one-component silane-modified sealants, the formulations of which are shown in Table 2.

[0083] Table 2 Formula (mass fraction) of flame-retardant one-component silane-modified sealant

[0084]

[0085]

[0086] Each flame-retardant one-component silane-modified sealant is prepared through the following process:

[0087] (1) Disperse the silane-modified resin, phosphorus-containing polyether plasticizer, flame-retardant filler, flame-retardant smoke suppressant, thixotropic agent, ultraviolet light absorber and light stabilizer in the planetary reactor for 15 minutes, Then vacuumize and dehydrate at 95°C for 120 minutes, and then lower the temperature to below 50°C in a vacuum state to obtain a homogeneous paste mixture with a moisture content of ≤1000ppm;

[0088] (2) To the reaction kettle in (1), add the formula amount of water remover, coupling agent and catalyst in sequence, and stir for 30 minutes under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com