High temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material and preparation method thereof

A flame-retardant sheath and low-shrinkage technology, which is applied in the field of high-temperature-resistant, low-shrinkage, halogen-free flame-retardant sheath material and its preparation, can solve problems such as poor heat resistance, and achieve good dimensional stability, not easy to ignite and spread, and not easy to shrink deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

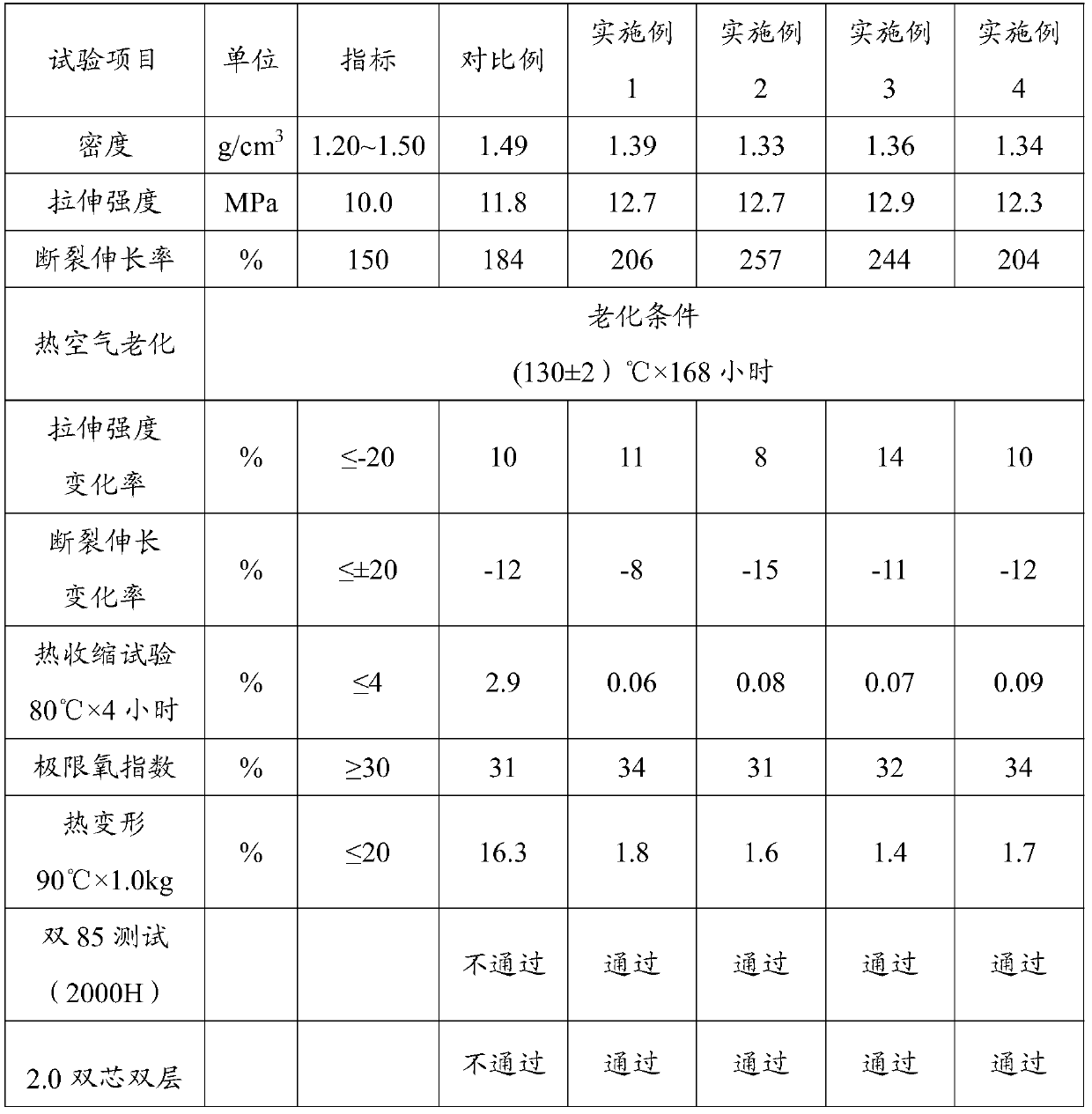

Examples

Embodiment 1

[0027] A high-temperature-resistant, low-shrinkage, halogen-free flame-retardant sheath material, comprising 56 parts of thermoplastic elastomer, 24 parts of functionalized polyolefin resin, 20 parts of grafted linear low-density polyethylene, and 2 parts of surface slippery agent in parts by weight , 2 parts of antioxidant, 3 parts of processing aid, 160 parts of flame retardant and 2 parts of tubular microcrystalline nano-char forming agent.

[0028] The thermoplastic elastomer is an ester elastomer (PET), and its melt index is 5.0 g / 10 min.

[0029] The melt index of the functionalized polyolefin resin (poe / eba) is 4.0 g / 10 min.

[0030] The grafted linear low-density polyethylene is maleic anhydride grafted, the grafting rate is 1%, and the density of the low-density polyethylene is 0.90g / cm 3 , The melt index is 4.0g / 10min.

[0031] The surface slippery agent is a compound of hyperdispersant DP-310 produced by Lubrizol and erucamide at a weight ratio of 2:3.

[0032] T...

Embodiment 2

[0041] A high-temperature-resistant, low-shrinkage, halogen-free flame-retardant sheathing material, comprising 55 parts of thermoplastic elastomer, 24 parts of functional polyolefin resin, 21 parts of grafted linear low-density polyethylene, and 2 parts of surface slippery agent in parts by weight , 2 parts of antioxidant, 3 parts of processing aid, 150 parts of flame retardant and 3 parts of tubular microcrystalline nano-char forming agent.

[0042] The thermoplastic elastomer is urethane elastomer (TPU), and its melt index is 5.0 g / 10 min.

[0043] The melt index of the functionalized polyolefin resin (poe / eba) is 4.0 g / 10 min.

[0044] The grafted linear low-density polyethylene is maleic anhydride grafted, the grafting rate is 1%, and the density of the low-density polyethylene is 0.90g / cm 3 , The melt index is 4.0g / 10min.

[0045]The surface slippery agent is a compound of hyperdispersant DP-310 produced by Lubrizol and oleic acid amide at a weight ratio of 1:2.

[00...

Embodiment 3

[0051] A high-temperature-resistant, low-shrinkage, halogen-free flame-retardant sheathing material, comprising 50 parts of thermoplastic elastomer, 26 parts of functionalized polyolefin resin, 24 parts of grafted linear low-density polyethylene, and 2 parts of surface slippery agent in parts by weight , 2 parts of antioxidant, 3 parts of processing aid, 150 parts of flame retardant and 1.5 parts of tubular microcrystalline nano-char forming agent.

[0052] The thermoplastic elastomer is a polyolefin elastomer with a melt index of 5.0 g / 10 min.

[0053] The melt index of the functionalized polyolefin resin (poe / eba) is 4.0 g / 10 min.

[0054] The grafted linear low-density polyethylene is maleic anhydride grafted, the grafting rate is 1%, and the density of the low-density polyethylene is 0.90g / cm 3 , The melt index is 4.0g / 10min.

[0055] The surface slippery agent is a compound of hyperdispersant DP-310 produced by Lubrizol and erucamide at a weight ratio of 1:3.

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com