Sound-absorbing flame-retardant vegetable oil-based polyurethane foam material and preparation method thereof

A foaming material and vegetable oil-based technology, which is applied in the field of vegetable oil-based polyurethane foaming materials and its preparation to achieve the effects of high mechanical strength, fast thermal conductivity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

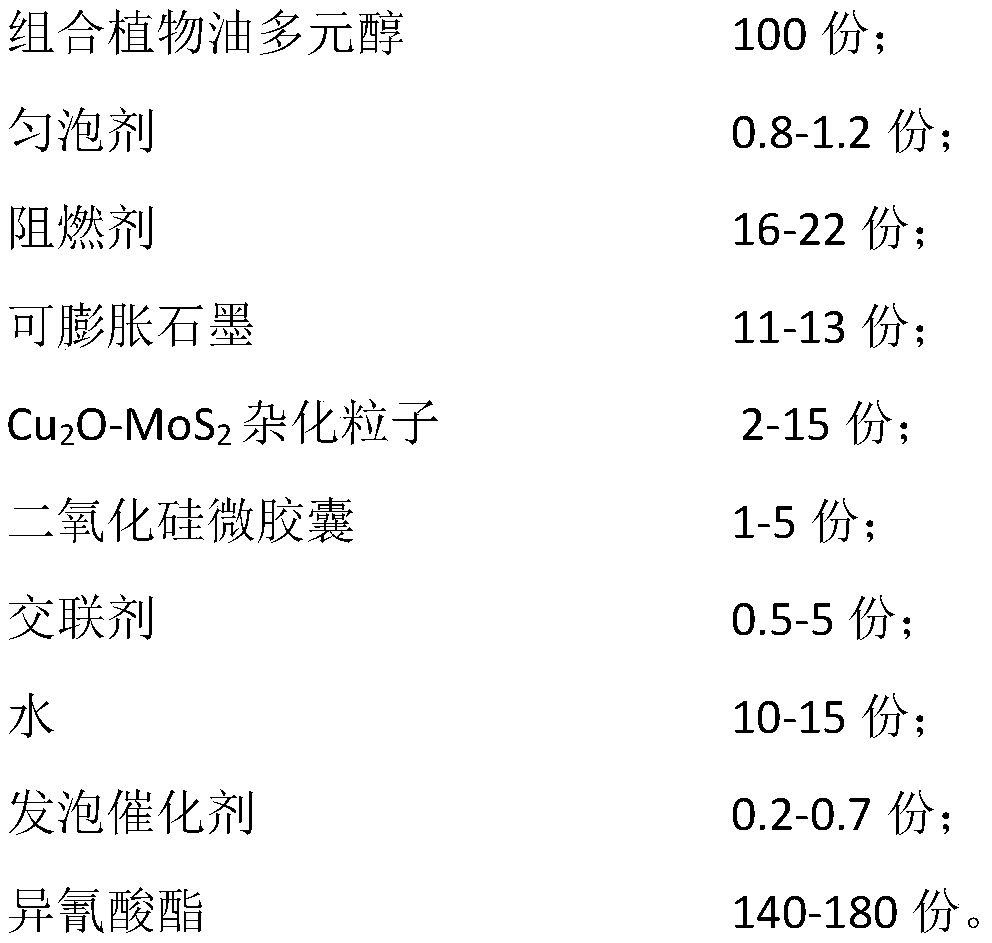

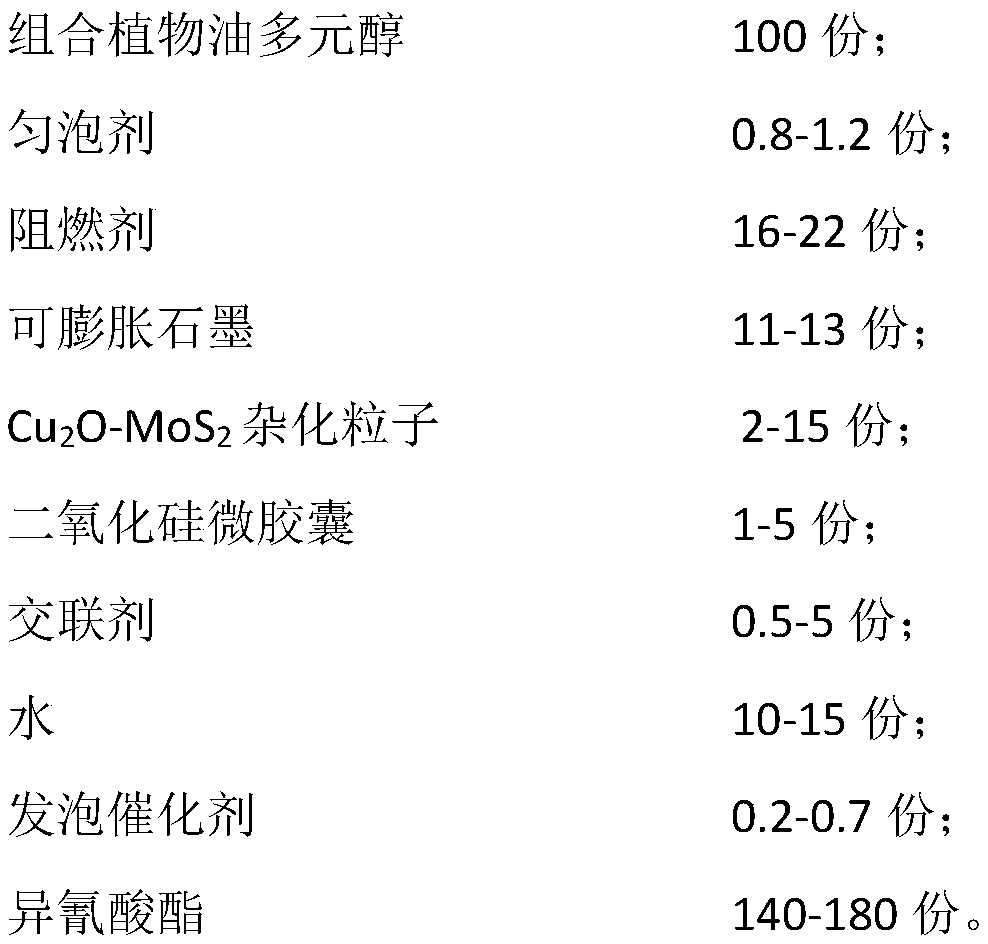

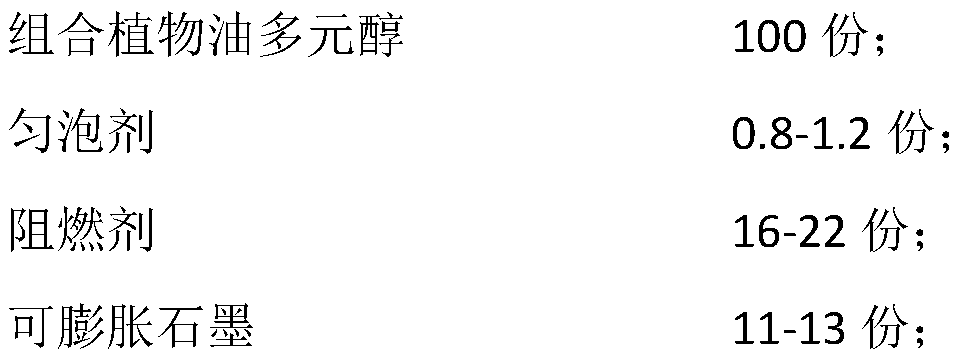

Method used

Image

Examples

Embodiment 6

[0048] Example 6 According to the formula of Example 5 in Table 1, mix material A and material C evenly, weigh the powder and place it in the same container, control the temperature of material A and B at 22-25°C, and control the temperature of material C At 18-20°C, add material A and material B into the foaming barrel, stir at 400r / min for 25s, then add the powder together, stir again at the same speed for 25s, then add material C into the foaming barrel, and stir at 1000r / min 12s, then quickly cast in the mold for reaction, trim the edges after the foam is matured, and cut according to the set thickness to obtain a bare foam board, and heat the bare board in an oven at 200°C for 2 minutes to obtain a polyurethane foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com