A sound-absorbing and flame-retardant vegetable oil-based polyurethane foam material and its preparation method

A foaming material, vegetable oil-based technology, applied in the field of vegetable oil-based polyurethane foaming materials and preparation, to achieve the effect of improving constant temperature characteristics, regular cells, and good cell opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

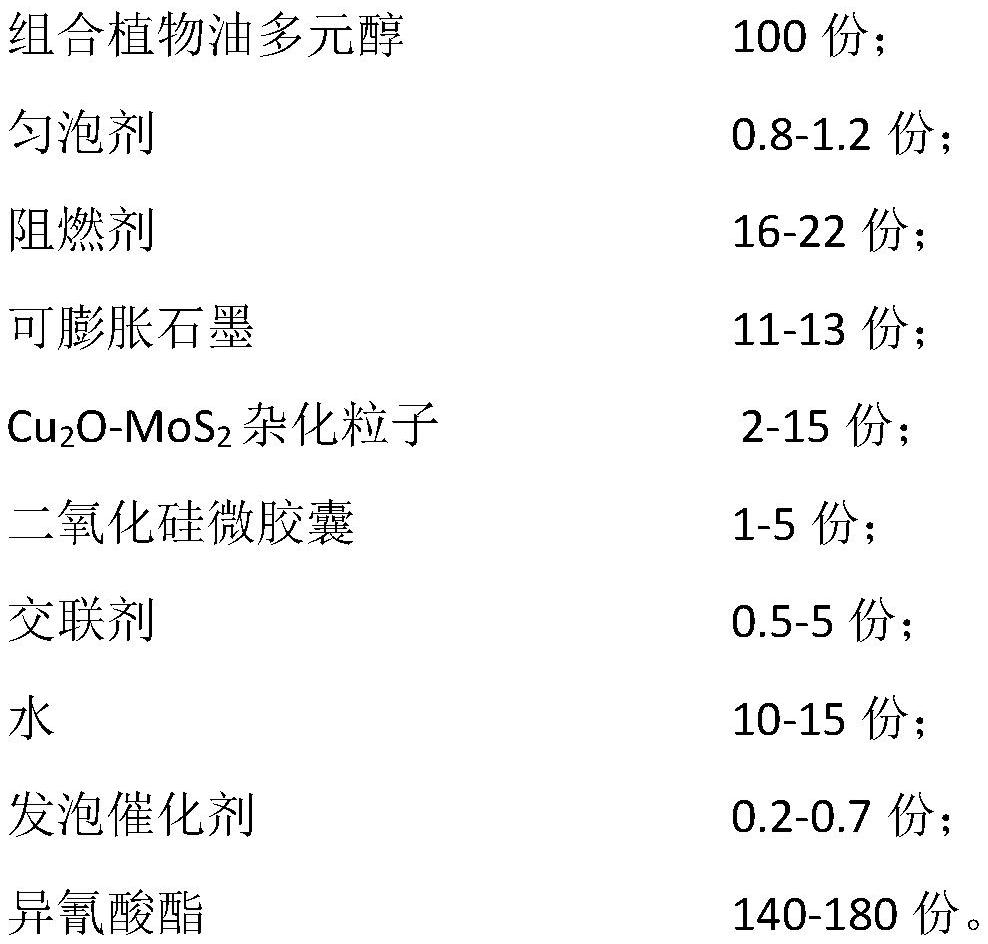

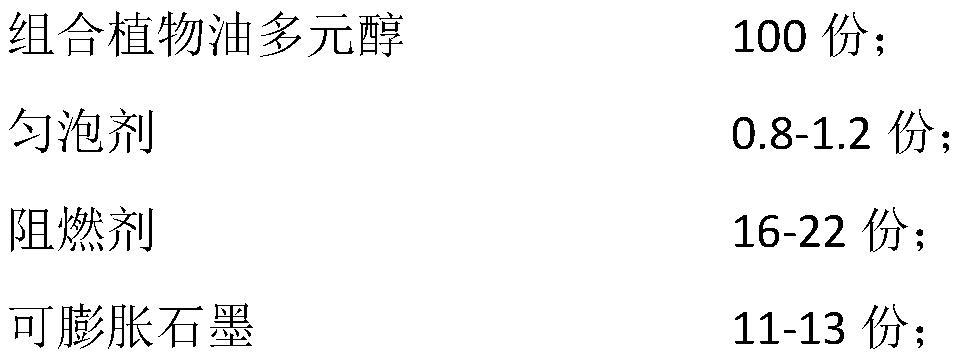

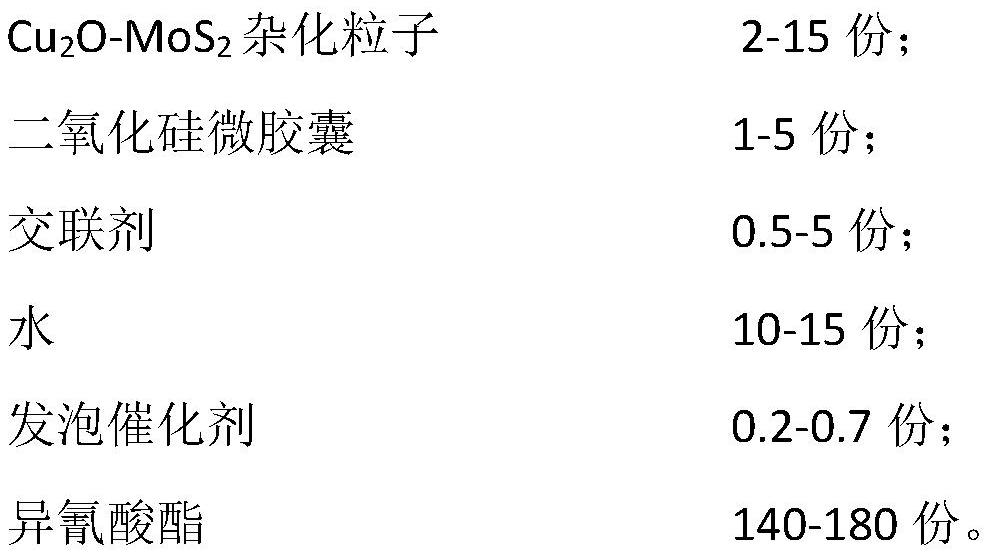

Method used

Image

Examples

Embodiment 6

[0048] Example 6 According to the formula of Example 5 in Table 1, material A and material C were mixed uniformly, the powder was weighed and placed in the same container, the temperature of material A and material B was controlled at 22-25 ° C, and the temperature of material C was controlled At 18-20°C, add materials A and B into the foaming barrel, stir at 400r / min for 25s, then add powder together, stir again at the same speed for 25s, then add material C into the foaming barrel, stir at 1000r / min 12s, and then quickly cast in the mold for reaction, the foam is matured and then trimmed and cut according to the set thickness to obtain a foamed bare board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com