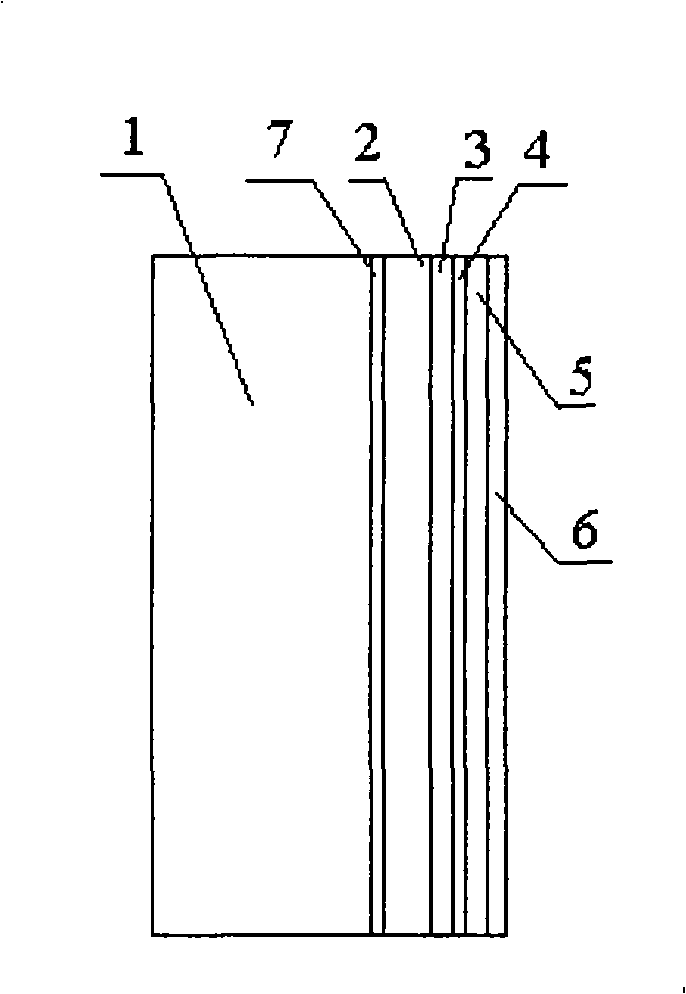

Pnenolic aldehyde foam board exterior wall internal insulation system and construction method

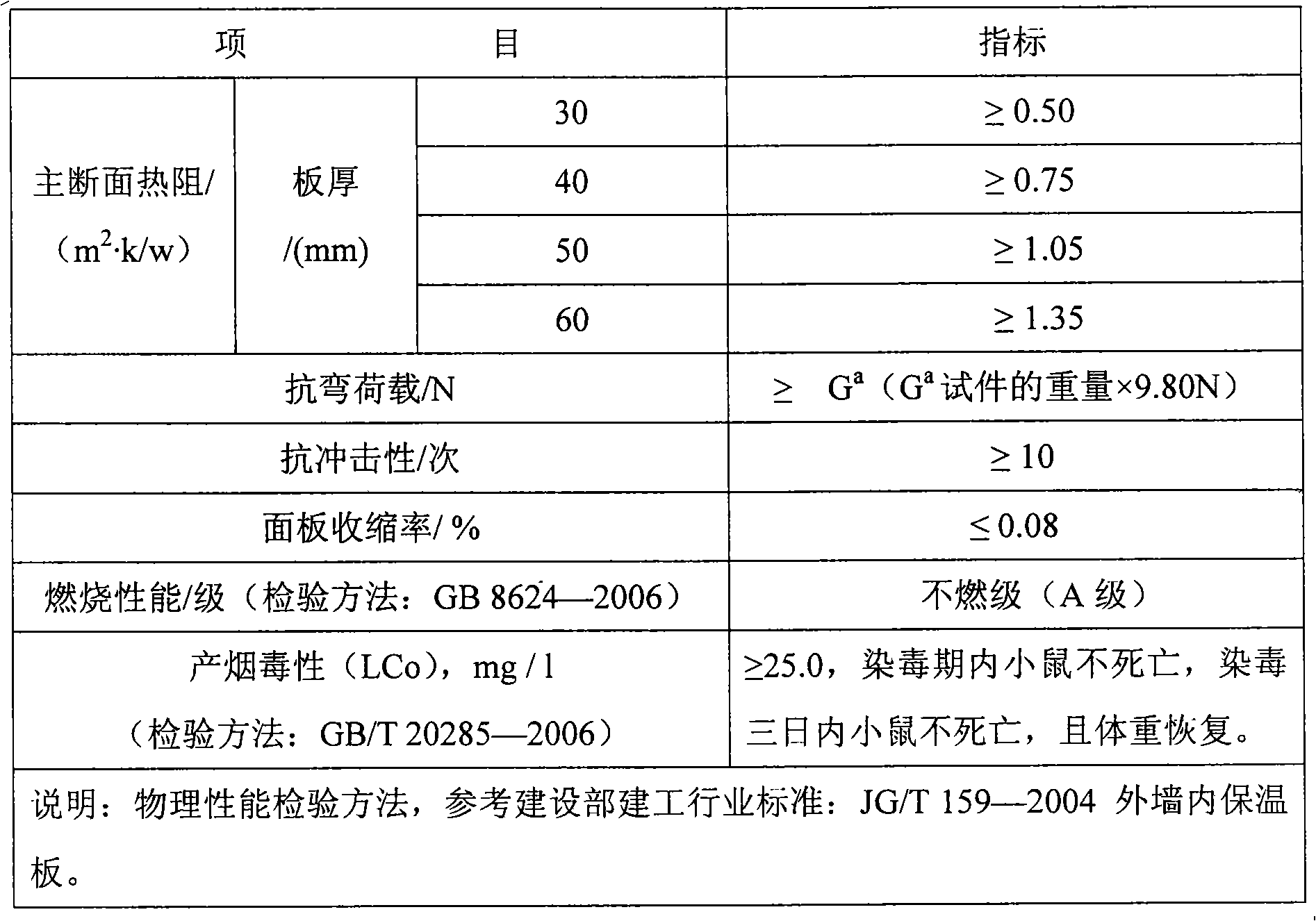

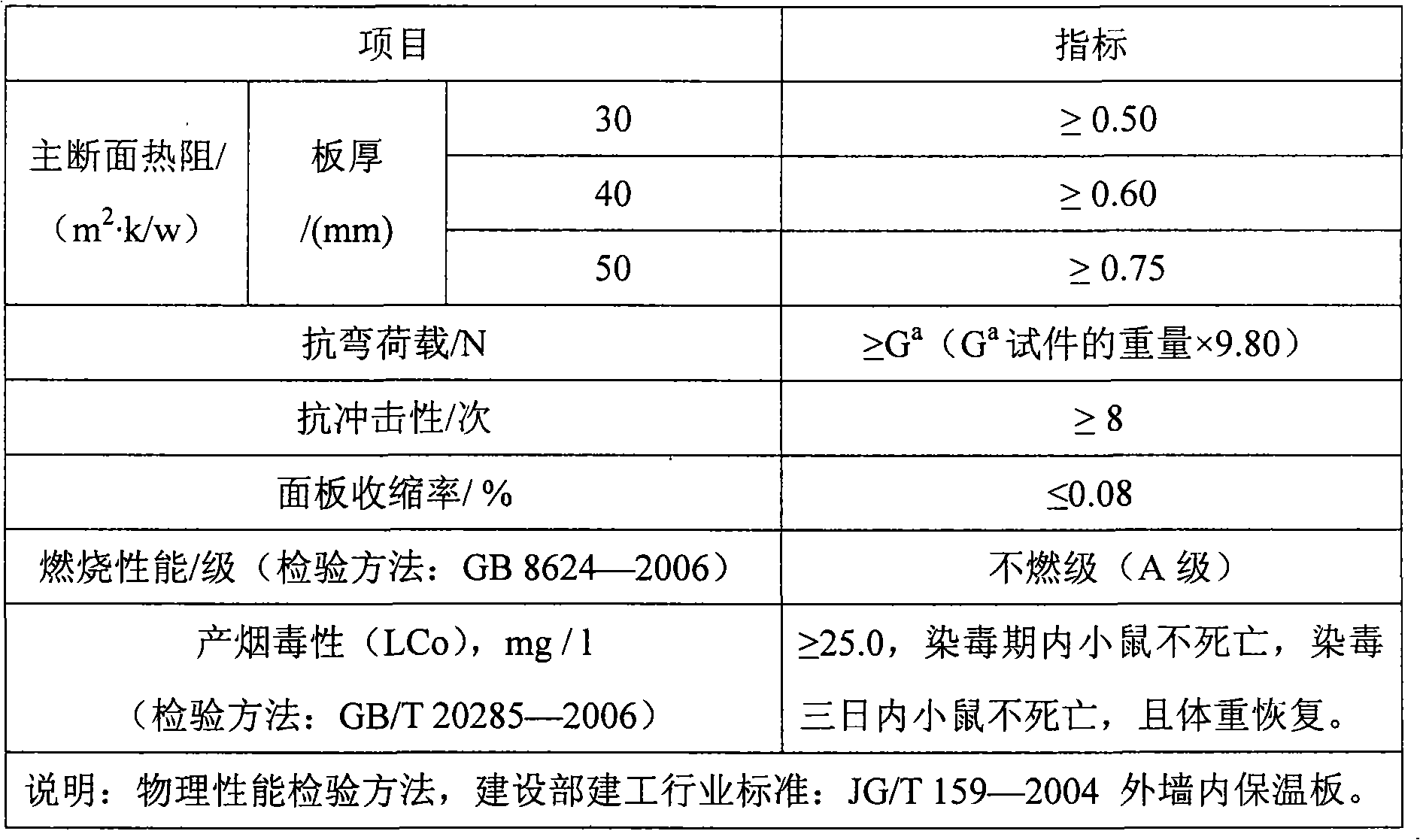

A phenolic foam board and thermal insulation system technology, applied in thermal insulation, building components, climate change adaptation and other directions, can solve problems such as threats to life and property safety, non-compliance with fire protection requirements, and general thermal insulation performance, achieving a wide range of uses and good environmental performance. , the effect of low smoke toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of the whole skin phenolic foam board:

[0041] Mix the A-stage phenolic resin, surfactant, initiator and foaming agent, inject it into the mold, mature and mold it at 80°C for 2 hours, and demould to obtain the phenolic foam;

[0042] The weight percent of each raw material is as follows:

[0043] A stage phenolic resin 80%

[0044] Surfactant 5%

[0045] Initiator 5%

[0046] Foaming agent 10%

[0047] Products produced by Shanghai Wangyue Engineering Material Technology Co., Ltd.;

[0048] Surfactant adopts foam stabilizer polysiloxane polyoxyethylene-polyoxypropylene (DC-193) produced by U.S. Air Products Company;

[0049] Initiator is selected from weight concentration and is 50% sulfuric acid;

[0050] The blowing agent is selected from trichlorofluoromethane.

[0051] (2) The construction process is as follows:

[0052] (1) Make a leveling layer with a thickness of 20mm on the inner base wall of the outer wall whose flatness is less than 2...

Embodiment 2

[0065] 1) Preparation of the whole skin phenolic foam board:

[0066] Mix the A-stage phenolic resin, surfactant, initiator and foaming agent, inject it into the mold, mature it at 90°C for 0.5 hours, demould, and obtain the phenolic foam;

[0067] The weight percent of each raw material is as follows:

[0068] A stage phenolic resin 86%

[0069] Surfactant 3%

[0070] Initiator 3%

[0071] Blowing agent 8%

[0072] The A-stage phenolic resin is produced by Shanghai Wangyue Engineering Material Technology Co., Ltd.;

[0073] Surfactant adopts foam stabilizer polysiloxane polyoxyethylene-polyoxypropylene (DC-193) produced by U.S. Air Products Company;

[0074] The initiator is selected from p-toluenesulfonic acid;

[0075] Foaming agent is selected from pentane;

[0076] (2) The construction process is as follows:

[0077] (1) Make a leveling layer with a thickness of 10mm on the inner base wall of the outer wall with a flatness of less than 2mm, and then apply an adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com