Micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material and preparation method thereof

A technology of flame-retardant cable material and interpenetrating network, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as inability to meet requirements, and achieve non-flammable spread, good dielectric properties and insulation , easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

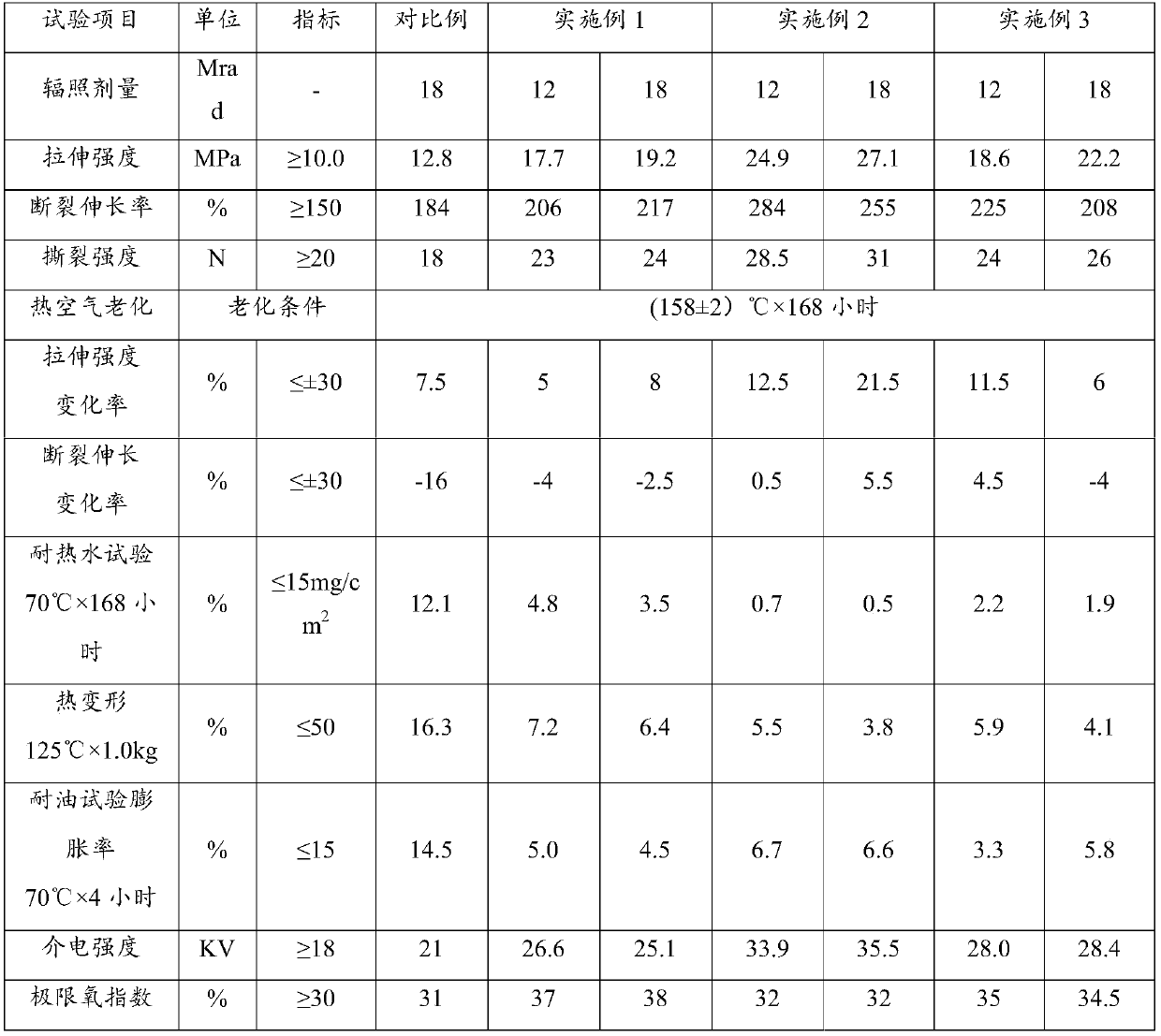

Embodiment 1

[0025] Micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material, in parts by weight, the cable material includes 25 parts of ethylene-vinyl acetate copolymer, 20 parts of silane-grafted linear low-density polyethylene, polyolefin thermoplastic elastic 25 parts of body, 15 parts of ultra-low density polyethylene, 15 parts of functional polyolefin resin, 2.5 parts of high molecular weight polysiloxane, 1.5 parts of cross-linking sensitizer, 2 parts of auxiliary cross-linking agent, 0.5 parts of chain extender, 180 parts of high-efficiency composite flame retardant, 2.5 parts of tubular microcrystalline nano-char forming agent, 2 parts of organosilane, 2 parts of antioxidant, and 1.5 parts of processing aid.

[0026] The ethylene-vinyl acetate copolymer is Dow 265, its vinyl acetate content is 28%, and its melt index is 3.0 g / 10 min.

[0027] Further, the grafting rate of silane-grafted linear low-density polyethylene is 1.5%, the unsatura...

Embodiment 2

[0040] The difference from Example 1 is to adjust the consumption of each component of the cable material, as follows:

[0041] Micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material, in parts by weight, the cable material includes 10 parts of ethylene-vinyl acetate copolymer, 40 parts of silane-grafted linear low-density polyethylene, polyolefin thermoplastic elastic 15 parts of body, 25 parts of ultra-low density polyethylene, 10 parts of functional polyolefin resin, 0.5 parts of high molecular weight polysiloxane, 0.5 parts of crosslinking sensitizer, 0.5 parts of auxiliary crosslinking agent, 0.1 part of chain extender, 120 parts of high-efficiency composite flame retardant, 2.5 parts of tubular microcrystalline nano-char forming agent, 1 part of organosilane, 0.5 part of antioxidant, and 0.5 part of processing aid.

Embodiment 3

[0043] The difference from Example 1 is to adjust the consumption of each component of the cable material, as follows:

[0044] Micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material, in parts by weight, the cable material includes 20 parts of ethylene-vinyl acetate copolymer, 30 parts of silane-grafted linear low-density polyethylene, polyolefin thermoplastic elastic 15 parts of body, 20 parts of ultra-low density polyethylene, 15 parts of functional polyolefin resin, 1 part of high molecular weight polysiloxane, 1 part of cross-linking sensitizer, 2 parts of auxiliary cross-linking agent, 0.25 parts of chain extender, 150 parts of high-efficiency composite flame retardant, 0.5 parts of tubular microcrystalline nano-char forming agent, 1 part of organosilane, 1.5 parts of antioxidant, and 1 part of processing aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com