High flame-retardant, halogen-free, low-smoke, low-toxicity single-component polyurethane foam sealant with oxygen index ≥ 32 and preparation method thereof

A polyurethane foam, high flame-retardant technology, applied in the field of one-component polyurethane foam caulking agent, can solve the problems of poor flame-retardant effect, high toxicity of combustion products, etc., to overcome technical prejudice, high flame retardancy, low smoke toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

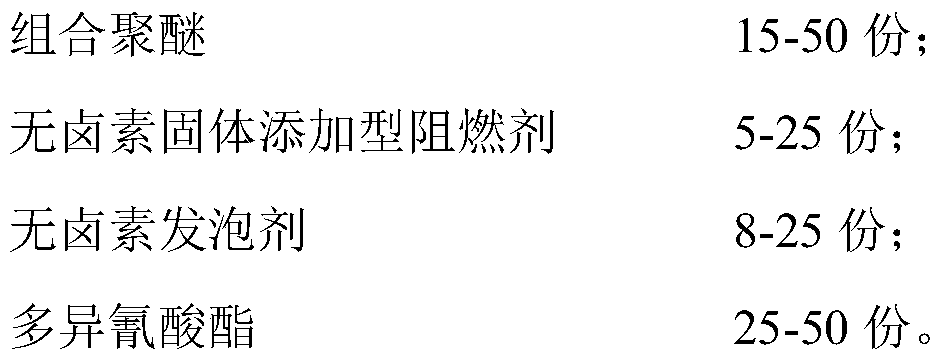

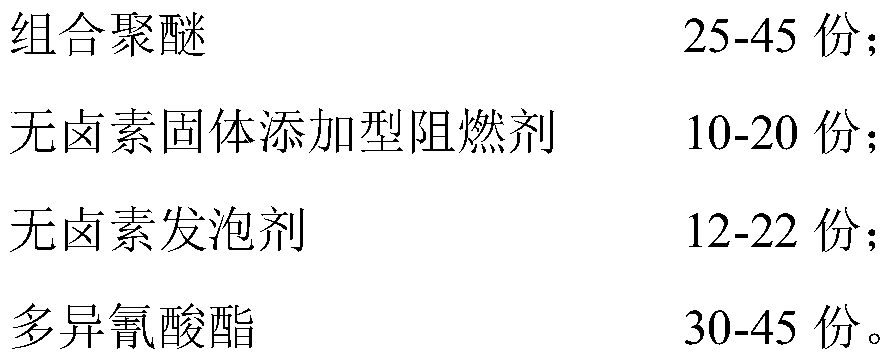

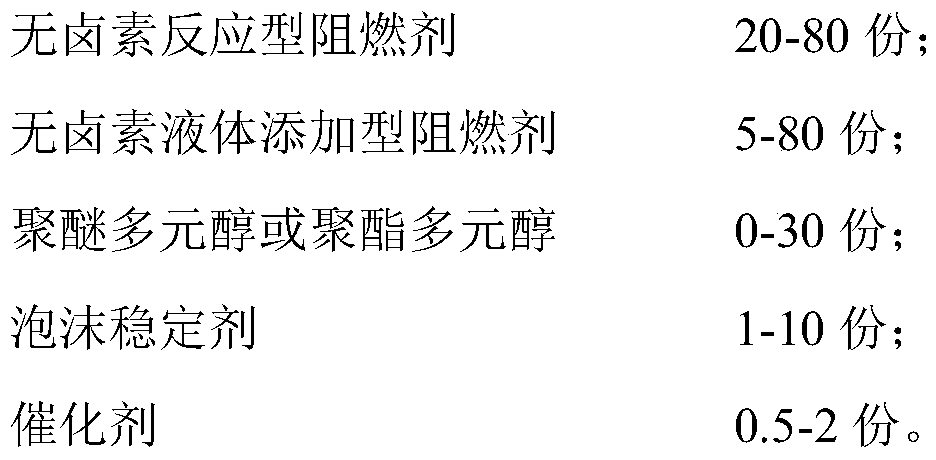

Method used

Image

Examples

Embodiment 1

[0074] Mix 10 parts of reactive halogen-free flame retardant polyether polyol AD-9958, 54 parts of halogen-free reactive flame retardant polyether polyol AD-9968, 8 parts of halogen-free liquid additive flame retardant TEP, 24 parts of halogen-free liquid The additive flame retardant DMMP, 3 parts of foam stabilizer B-8871, and 1 part of catalyst DMDEE are mixed. The mixing method can be carried out by any common physical means, such as stirring. Mix evenly to obtain combined polyether.

[0075] Using the aerosol filling equipment, add 30 parts of the combined polyether prepared above, 15 parts of expandable graphite KP9980-200 and 38 parts of polyisocyanate M20S into the aerosol tank, and seal the valve. Pour in 7.5 parts of dimethyl ether and 9.5 parts of propylene butane (a total of 17 parts of the mixture of dimethyl ether and propylene butane) foaming agent, shake and mix for 5 minutes, and stand at room temperature for 24 hours to obtain the product of the present inven...

Embodiment 2

[0078] In addition to taking 20 parts of reactive halogen-free flame-retardant polyether polyol DMD-509, 40 parts of halogen-free reactive flame-retardant polyether AD-9968, 36 parts of halogen-free liquid additive flame retardant DMMP, and 3 parts of foam stabilizer B -8871, 1 part of catalyst DMDEE, except for the composition and proportion of the combined polyether, the others are the same as in Example 1. The foam sample of the high flame-retardant, halogen-free, low-smoke and low-toxicity one-component polyurethane foam sealant product of the present invention is tested according to the standard GB / T2406.2-2009 for the oxygen index of the product, and according to GB / T8323.2- The smoke density of the product was tested according to the 2008 standard, and the smoke toxicity of the product was tested according to the method 4.4 in the TB / 3237-2010 standard. The test results are shown in Table 1.

Embodiment 3

[0080] In addition to taking 10 parts of reactive halogen-free flame-retardant polyol AD-9958, 46 parts of halogen-free reactive flame-retardant polyether AD-9968, 8 parts of polyester polyol PS-2352, and 32 parts of liquid-added halogen-free polyol Combustion agent DMMP, 3 parts of foam stabilizer B-8871, 1 part of catalyst DMDEE, except for the composition and proportioning of the combined polyether, the others are the same as in Example 1. The foam sample of the high flame-retardant, halogen-free, low-smoke and low-toxicity one-component polyurethane foam sealant product of the present invention is tested according to the standard GB / T2406.2-2009 for the oxygen index of the product, and according to GB / T8323.2- The smoke density of the product was tested according to the 2008 standard, and the smoke toxicity of the product was tested according to the method 4.4 in the TB / 3237-2010 standard. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com