Flame-retardant high impact polystyrene compound and preparation method thereof

A technology of flame-retardant high-impact polystyrene and polystyrene, which is applied in the field of flame-retardant high-impact polystyrene composites and its preparation, can solve the problems of reduced impact resistance, large proportion of BaSO4, and high cost, and achieve Effect of reducing mass loss rate, improving anti-aging performance, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

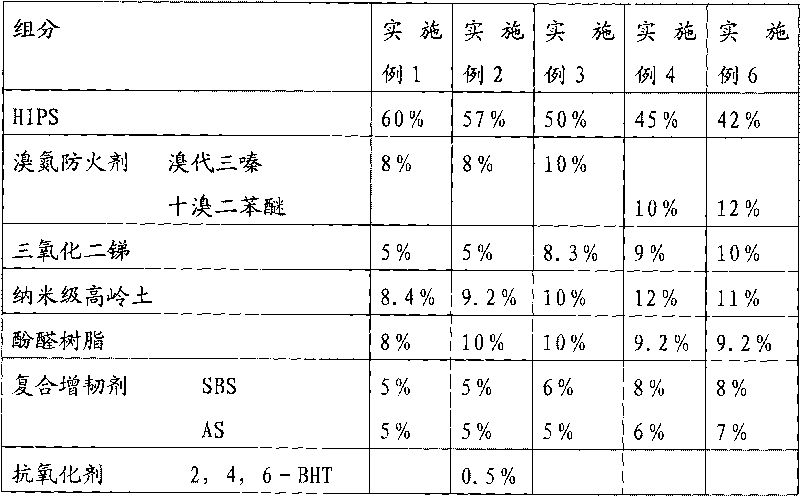

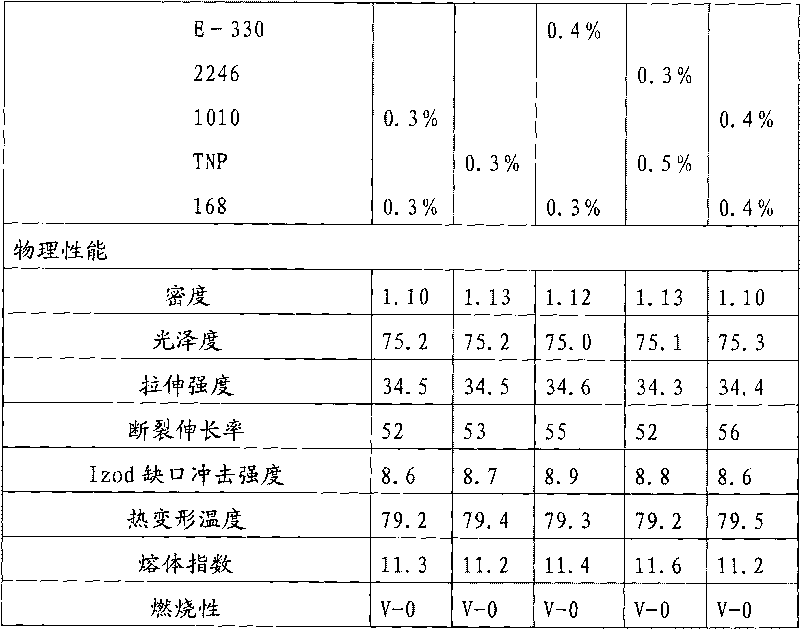

[0024] The preparation method is as follows: take nano-scale kaolin containing silicon dioxide, aluminum oxide, ferric oxide, magnesium oxide, and antimony dioxide with fireproofing effects, dry it, put it into a high-speed mixer, heat, and stir , when the temperature rises to 120°C, add chelating plastic additives to carry out affinity modification; the modified nano-scale kaolin and high-impact polystyrene, phenolic resin, bromine-nitrogen flame retardant, three Antimony oxide, styrene-butadiene-styrene block copolymer, acrylonitrile-styrene resin, phenolic antioxidant and phosphate antioxidant, put into a mixer, stir well; the mixture after stirring Melting, pressure 15~30MPa, temperature 175℃~230℃, extrusion from mixer, pelletizing, packaging.

[0025] In this experiment, HIPS with a butadiene rubber content of 3-10% was used, and bromine nitrogen flame retardants were brominated triazine and decabromodiphenyl ether.

[0026] The composites prepared in each embodiment wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com