Preparation method of EVA nano flame-retardant compound based on magnesium/zinc/boron/nitrogen synergy

A nano flame retardant and composite technology, applied in the field of nano materials, can solve the problem of low flame retardant efficiency of EVA/MH system, and achieve the effects of slowing heat/mass exchange, improving mechanical properties, reducing heat release and smoke release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

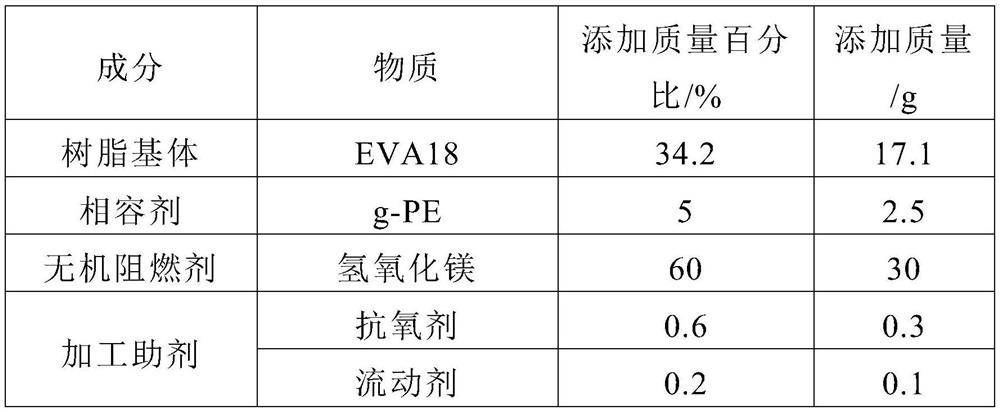

[0035] An ethylene-vinyl acetate copolymer flame-retardant composite material, based on the total mass of the composite material as 100%, the components and mass percentages are as follows:

[0036]

[0037]

[0038] Specific steps are as follows:

[0039] (1) Dry ethylene-vinyl acetate copolymer, compatibilizer, magnesium hydroxide, and processing aids in an oven at 60°C, and then mix all raw materials in an internal mixer for 15 minutes. The temperature is 175°C, the rotation speed is 70rpm, and the mixed sample is preliminarily pressed into a sheet using a double-roll mill, and the roller temperature is 105°C.

[0040] (3) The sheet is hot-pressed with a preset program by a flat vulcanizer, and the molding temperature is 150°C.

[0041] Test results: vertical combustion V-1 level, oxygen index 36.2%. Cone calorimeter test results show that the peak heat release rate is 180.84kW / m 2 , the total smoke release rate is 584.66m 2 / m 2 , 47.90% of residual carbon quali...

Embodiment 2

[0043] An ethylene-vinyl acetate copolymer flame-retardant composite material, based on the total mass of the composite material as 100%, the components and mass percentages are as follows:

[0044]

[0045] Specific steps are as follows:

[0046] (1) Dry ethylene-vinyl acetate copolymer, compatibilizer, magnesium hydroxide, and processing aids in an oven at 60°C, and then mix all raw materials in an internal mixer for 15 minutes. The temperature is 150°C, the rotation speed is 80rpm, and the mixed sample is preliminarily pressed into a sheet using a double-roll mill, and the roller temperature is 105°C.

[0047] (3) The sheet is hot-pressed with a preset program by a flat vulcanizer, and the molding temperature is 150°C. Test results: vertical combustion V-1 level, oxygen index 36.0%. Cone calorimeter test results show that the peak heat release rate is 185.14kW / m 2 , the total smoke release rate is 610.34m 2 / m 2 , residual carbon mass 47.54%. The tensile strength is ...

Embodiment 3

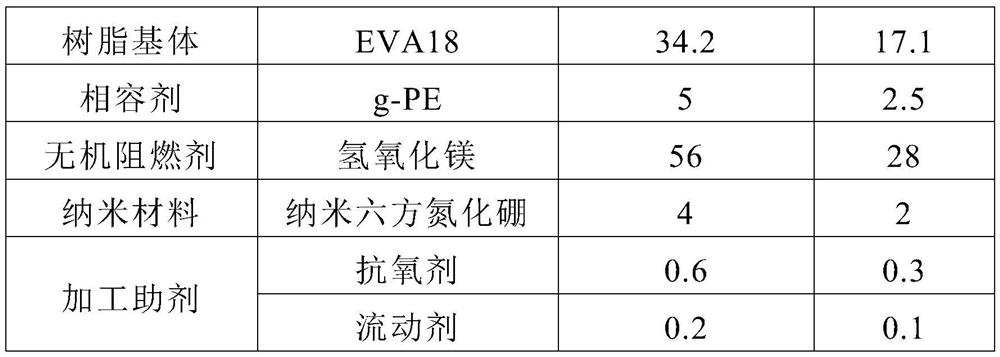

[0049] An ethylene-vinyl acetate copolymer flame-retardant composite material, based on the total mass of the composite material as 100%, the components and mass percentages are as follows:

[0050]

[0051] Specific steps are as follows:

[0052] (1) Dry ethylene-vinyl acetate copolymer, compatibilizer, magnesium hydroxide, and processing aids in an oven at 60°C, and then mix all raw materials in an internal mixer for 20 minutes. The temperature is 150°C, the rotation speed is 80rpm, and the mixed sample is preliminarily pressed into a sheet using a double-roll mill, and the roller temperature is 110°C.

[0053] (3) The sheet is hot-pressed with a preset program by a flat vulcanizer, and the molding temperature is 150°C.

[0054] Test results: vertical combustion V-0 level, oxygen index 36.5%. Cone calorimeter test results show that the peak heat release rate is 169.14kW / m 2 , the total smoke release rate is 362.59m 2 / m 2 , The residual carbon mass is 50.88%. The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat release rate | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com