Halogen-free expanded flame retardant cable outer sheath material composition and preparation method thereof

An intumescent flame retardant and composition technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of damage, loss of material mechanical properties, etc., and achieve the effect of simple process, good mechanical properties, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

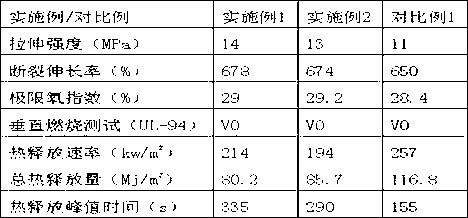

Embodiment 1

[0015] Embodiment 1: Weigh 1.5% of halloysite and 1% of silane coupling agent, pour them into a high-speed mixer and mix for more than 5 minutes; then weigh 21% of ammonium polyphosphate flame retardant, 7% of pentaerythritol flame retardant Pour into a high-speed mixer and mix for more than 5 minutes; then add 66% ethylene vinyl acetate resin with a vinyl acetate content of 18%, 4% ethylene-vinyl acetate-maleic anhydride copolymer compatibilizer, 2% Mix antioxidant and 1% release agent for more than 3 minutes; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, and the release agent is hard Calcium fatty acid, the silane coupling agent is γ-aminopropyltriethoxysilane. The mixed material is put into a double-roll mill for melt blending to obtain the composition for the halogen-free intumescent flame-retardant cable outer sheath material of the present invention.

[0016] The obtained composition was vulcanized into a sheet in a vulca...

Embodiment 2

[0017] Embodiment 2, take 1.5% halloysite, 1% silane coupling agent by weighing, pour into high-speed mixer and mix for more than 5 minutes; Then weigh 21% ammonium polyphosphate flame retardant, 7% pentaerythritol flame retardant Pour the agent into a high-speed mixer and mix for more than 5 minutes; then add 64% ethylene vinyl acetate resin with a vinyl acetate content of 18%, 6% ethylene-vinyl acetate-maleic anhydride copolymer compatibilizer, 2% anti Oxygen agent and 1% release agent are mixed for more than 3 minutes; the antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, and the release agent is stearin Calcium acid, the silane coupling agent is γ-aminopropyltriethoxysilane. The mixed material is put into a double-roll mill for melt blending to obtain the composition for the halogen-free intumescent flame-retardant cable outer sheath material of the present invention.

[0018] The obtained composition was vulcanized into a sheet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com