Carbon quantum dot-polymer composite material, and preparation method and application thereof

A technology of carbon quantum dots and composite materials, which is applied in the field of carbon quantum dot-polymer composite materials and its preparation and application, and can solve problems such as poor dispersion, unsatisfactory flame retardant effect, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

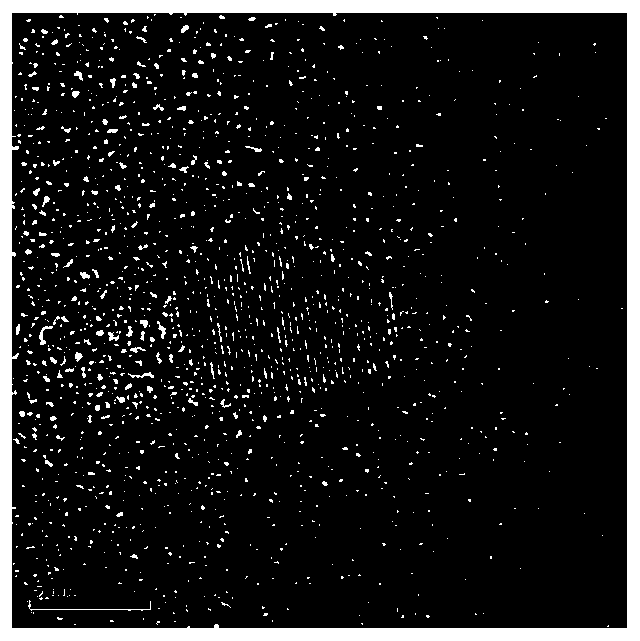

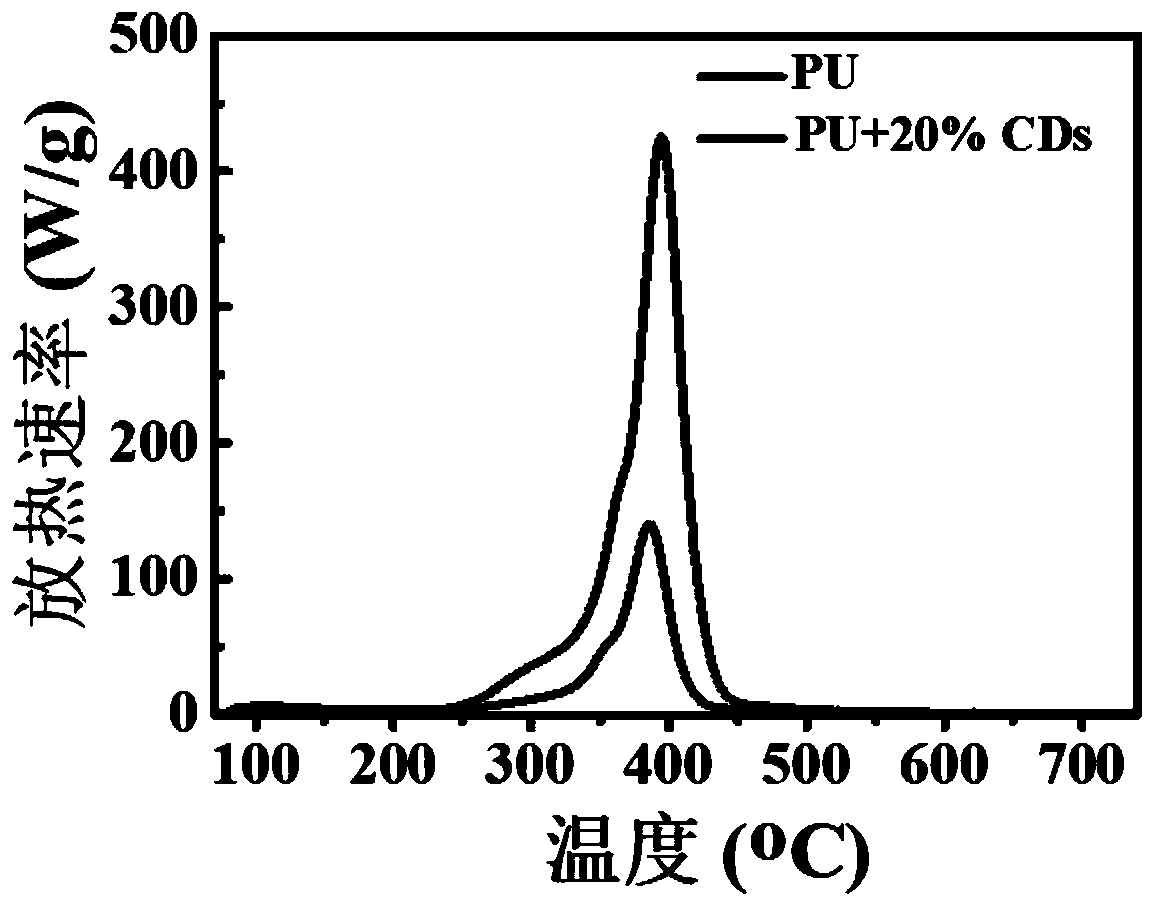

[0021] With carbon quantum dot powder (the TEM figure of carbon quantum dot sees figure 1 ) mixed with polyurethane evenly, then the mixture is extruded by a screw extruder and pelletized. Among them, carbon quantum dots and polyurethane are mixed at a mass ratio of 1:4, the melting temperature of the screw extruder is set at 190°C, and the speed of the main machine is 25r / min. The flame retardant properties of the extruded masterbatch were then tested. figure 2 It is the physical picture of the masterbatch extruded and pelletized by the screw extruder. The masterbatch is uniform black, indicating that the carbon quantum dots are uniformly dispersed in the polymer. image 3 It is the heat release rate curve of the composite material mixed with carbon quantum dots and polyurethane material at a mass ratio of 1:4. Table 1 is other flame retardant test parameters. The heat release ability decreased by 57.5%, the peak heat release rate decreased by 65.8%, the total heat relea...

Embodiment 2

[0026] The carbon quantum dot powder is uniformly mixed with polyvinylpyrrolidone (PVP) particles, and then the mixture is extruded through a screw extruder and pelletized. Among them, carbon quantum dots and polyurethane are mixed at a mass ratio of 1:4, the melting temperature of the screw extruder is set at 140°C, and the speed of the main machine is 30r / min. The flame retardant properties of the extruded masterbatch were then tested. The heat release ability decreased by 50.6%, the peak heat release rate decreased by 62.8%, the total heat release decreased by 58.8%, and the maximum decomposition temperature decreased by 2.3°C. Figure 4 It is the flame retardant effect diagram of pure polymer and carbon quantum dots / polyvinylpyrrolidone composite. in, Figure 4 Middle a-d are photos of pure polyvinylpyrrolidone when the burning time is 1s, 2s, 3s, 4s; Figure 4 Middle e-h are photos of carbon quantum dots and polyvinylpyrrolidone composites when the burning time is 1s, ...

Embodiment 3

[0028] The carbon quantum dot powder is uniformly mixed with nylon 6 (PA6) resin, and then the mixture is extruded through a screw extruder and pelletized. Among them, carbon quantum dots and nylon 6 are mixed at a mass ratio of 1:9, the melting temperature of the screw extruder is set at 260°C, and the speed of the main machine is 30r / min. The flame retardant properties of the extruded masterbatch were then tested. The heat release ability decreased by 21.5%, the peak heat release rate decreased by 28.3%, the total heat release decreased by 25.6%, and the maximum decomposition temperature decreased by 0.6°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com