A kind of carbon quantum dot-polymer composite material and its preparation and application

A technology of carbon quantum dots and composite materials, which is applied in the field of carbon quantum dot-polymer composite materials and its preparation and application, and can solve problems such as complex process, poor dispersion, and unsatisfactory flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

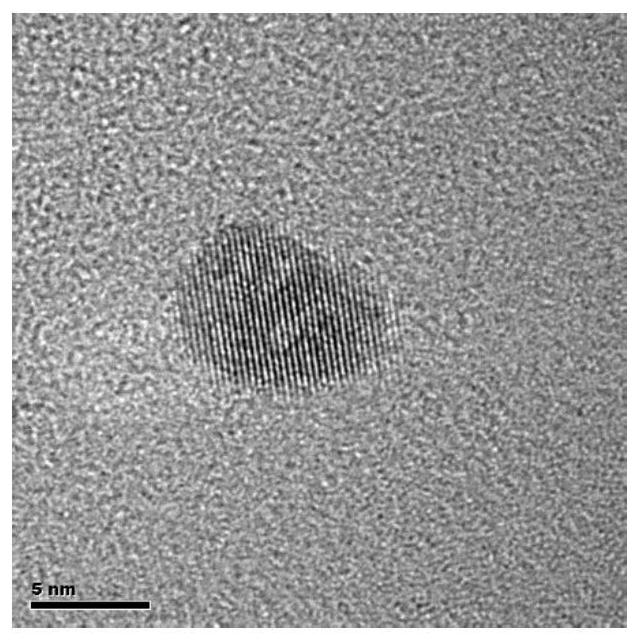

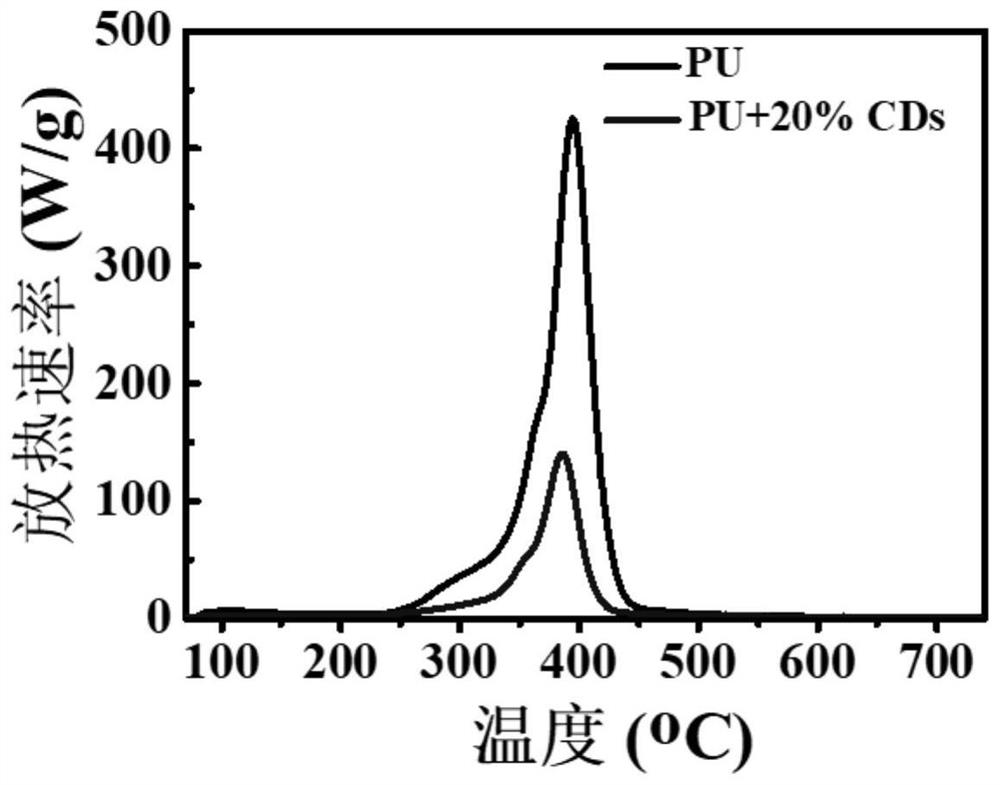

[0021] The carbon powder quantum dots (QDs carbon TEM see FIG. figure 1 ) Mixed with the polyurethane, and then the mixture was extruded by a screw extruder and pelletized. Wherein the carbon polyurethane quantum dots 1: 4 ratio by mass were mixed, melt-screw extruder set to 190 deg.] C temperature, host speed 25r / min. Subsequently extruded masterbatch of flame retardant performance test. figure 2 Said screw extruder and pelletizing the masterbatch physical FIG. Uniform black masterbatch, quantum dots indicate the carbon uniformly dispersed in the polymer. image 3 Carbon quantum dots polyurethane material according to 1: 4 by mass mixed graph of heat release rate of the composite ratio. Table 1 flame test for other parameters. Heat release ability decreased by 57.5%, the peak heat release rate decreased by 65.8%, the total heat release decreased 61.3%, the maximum decomposition temperature dropped 1.7 ℃.

[0022] Table 1 Carbon quantum dot - Polyurethane flame retardant properti...

Embodiment 2

[0026] The carbon powder and the quantum dots polyvinyl pyrrolidone (PVP) particles are mixed uniformly, then the mixture was extruded by a screw extruder and pelletized. Wherein the carbon polyurethane quantum dots 1: 4 ratio by mass were mixed, melt-screw extruder set to 140 deg.] C temperature, host speed 30r / min. Subsequently extruded masterbatch of flame retardant performance test. Heat release ability decreased by 50.6%, the peak heat release rate decreased by 62.8%, the total heat release decreased 58.8%, the maximum decomposition temperature decreased 2.3 ℃. Figure 4 Pure polymer and carbon quantum dot / polyvinylpyrrolidone FIG composite flame-retardant effect. in, Figure 4 A-d in a pure polyvinyl pyrrolidone burning time of 1s, 2s, 3s, 4s when the picture; Figure 4 E-h of the quantum dots is a carbon composite polyvinylpyrrolidone burn time of 1s, 2s, 3s, 4s when the photograph. As can be seen from the figure, the quantum dots polyvinylpyrrolidone carbon composites exh...

Embodiment 3

[0028] The carbon powder and the quantum dots nylon 6 (PA6) resin is mixed, then the mixture was extruded by a screw extruder and pelletized. Wherein the quantum dots nylon 6 carbon by 1: 9 mass ratio of mixing, screw extruder melt temperature is set to 260 ℃, host speed 30r / min. Subsequently extruded masterbatch of flame retardant performance test. Heat release ability decreased by 21.5%, the peak heat release rate decreased by 28.3%, the total heat release decreased by 25.6%, the maximum decomposition temperature dropped 0.6 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com