Patents

Literature

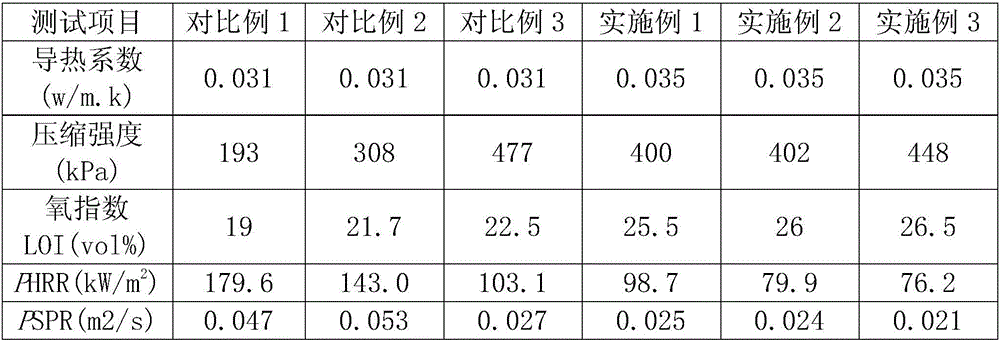

30results about How to "Reduce peak heat release rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified amino resin expansion type water flame-proof paint

InactiveCN101117510AImprove flame retardant performanceIncreased resistance to ignitionFireproof paintsEmulsion paintsPliabilityMelamine

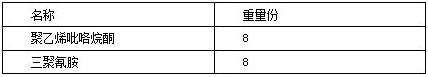

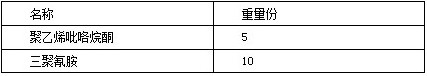

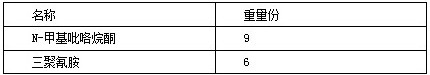

The present invention relates to amino resin intumescent aqueous flame retardant coating, in particular to an intumescent aqueous flame retardant coating. The present invention eliminates the release of harmful organic volatile compounds of the inflaming-retardant coating in use, improving poor fire resistant performance of dewatering catalyst due to a high disassembling temperature, solving the problems of long manufacturing period, low efficiency and high cost of the inflaming-retardant wood materials. The materials for the present invention comprises amino resin, polyvinyl acetal resin, dewatering catalyst, melamine, charring agents, dope assistant, antifoaming agent, palette filling and water. The present invention has storage for a long time, good cohesion, slow and low emission of heat and low emission of smoke, enjoying good flexibility and good strike-resistant performance; furthermore, the present invention can be manufactured easily and used conveniently and can be easily popularized without emission of harmful organic volatile in use. Compared with a prior wooden inflaming-retardant liquid, the present invention has the advantages of simple process, convenient operation, low cost and high efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY

Micro foam polystyrene group composite material of wood and plastic, and method of producing the same

A micro-foaming polystyrene wood-plastic composite material and the preparation method relates to a micro foaming wood-plastic composite material and the preparation method. The present invention solves the problems of poor impact resistance and easy combustion of the current wood-plastic composite material. The present invention is made of wood fiber material, coupling agent, plasticizer, lubricant, polystyrene, foamer, assistant foamer, fire retardants and smoke suppressant according to a weight portion. The preparation method is as follows: first, hot mixing; secondly, cooling and mixing; thirdly, extruding and molding. Then the micro-foaming polystyrene wood-plastic composite material can be made. The micro-foaming polystyrene wood-plastic composite material of the present invention has the advantages of small density, good fire-resistant and smoke-suppression effects, and impact resistance.

Owner:NORTHEAST FORESTRY UNIVERSITY

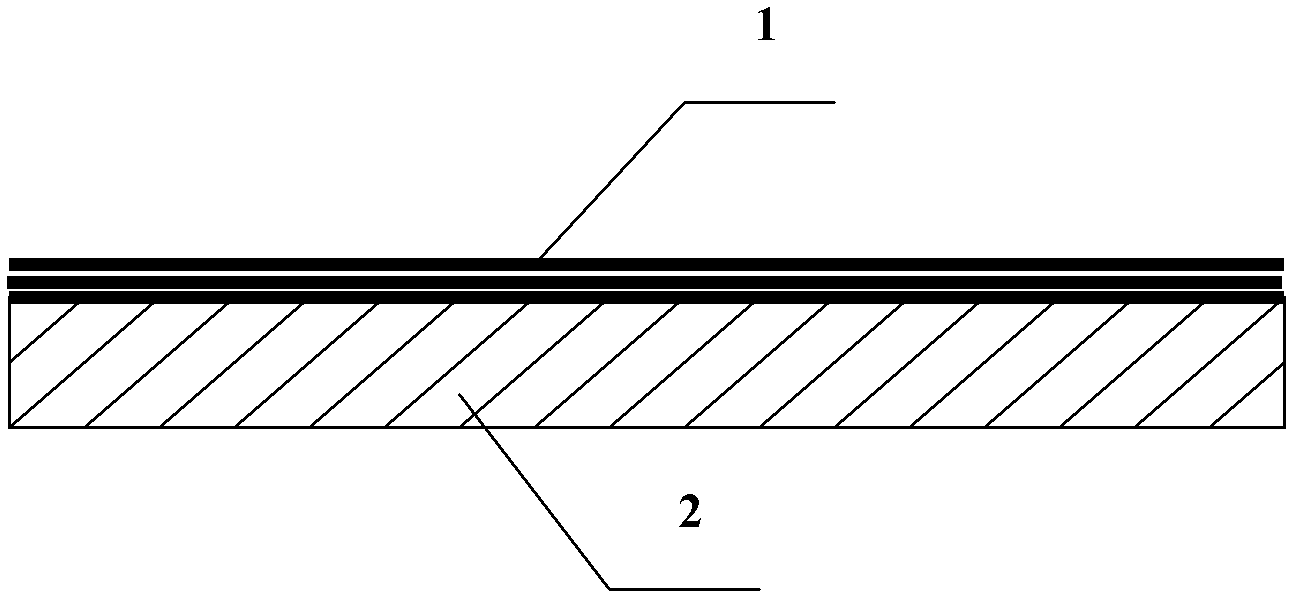

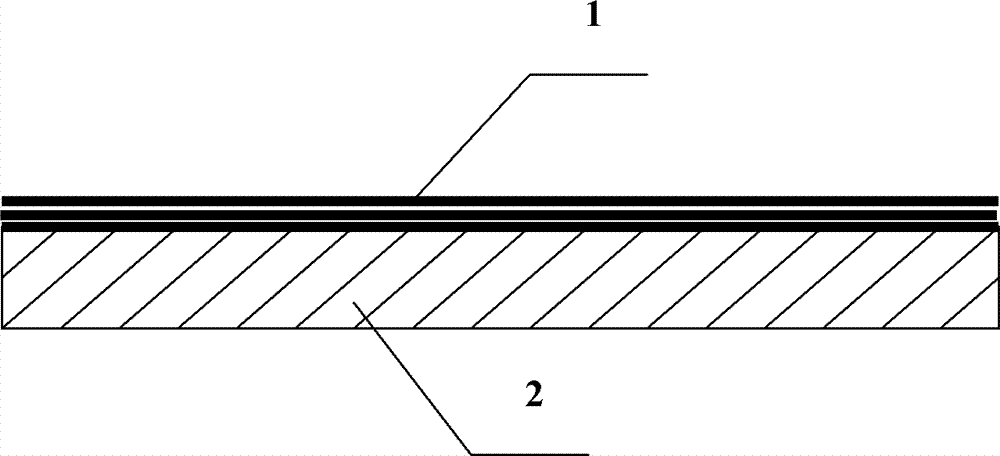

Method for preparing carbon nanometer paper flame resistant polymer matrix composite material

InactiveCN103317785AImprove flame retardant propertiesShorten ignition timeGlass/slag layered productsCarbon nanotubePeak value

The invention provides a method for preparing a carbon nanometer paper flame resistant polymer matrix composite material, which is intended to solve problems that: the current resin-based fiber reinforced composite materials exist unsafe factors of flammability, high combustion speed, difficult extinguishing, and environment pollution because of toxic gas generation; and addition of nano-materials like carbon nanotubes in a composite material can improves flame resistance of the composite material, but flame resistant and fireproof characteristics, and dispersibility and content of the nano-materials like carbon nanotubes affect integral mechanical properties of the composite material. The method comprises: adding at least one flame resistant material into a carbon nanometer paper structure, and then using the carbon nanometer paper structure as a flame resistant external layer of the composite material to form the carbon nanometer paper flame resistant polymer matrix composite material. The carbon nanometer paper flame resistant polymer matrix composite material has a good flame resistant characteristic, and a plurality of flame resistant materials is added into the carbon nanometer paper structure, thereby greatly raising flame resistant and fireproof characteristics of the composite material. Compared to a composite material without carbon nanometer paper, ignition time of the carbon nanometer paper flame resistant composite material can be reduced more than 10-30%, and a peak value of heat releasing speed can be reduced more than 15-45%, and a smoke releasing total amount can be reduced more than 10-30%.

Owner:SHENYANG AEROSPACE UNIVERSITY

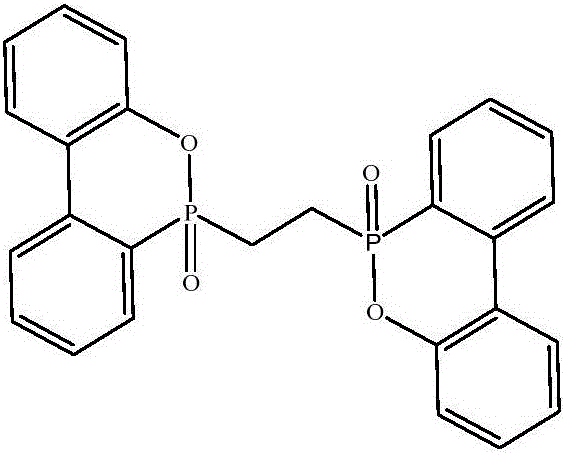

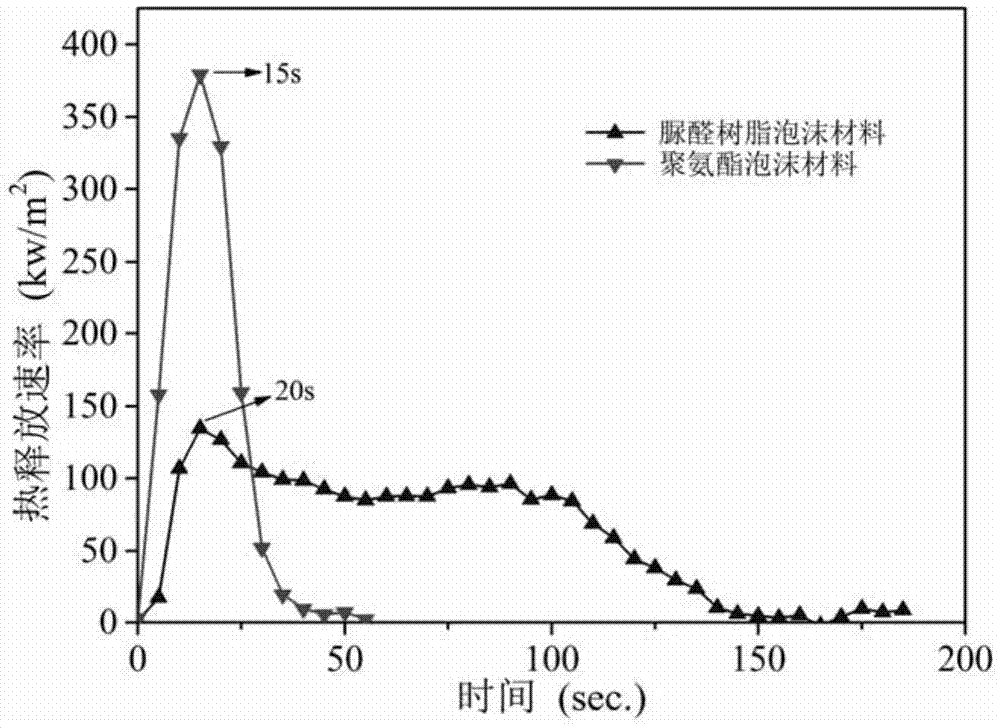

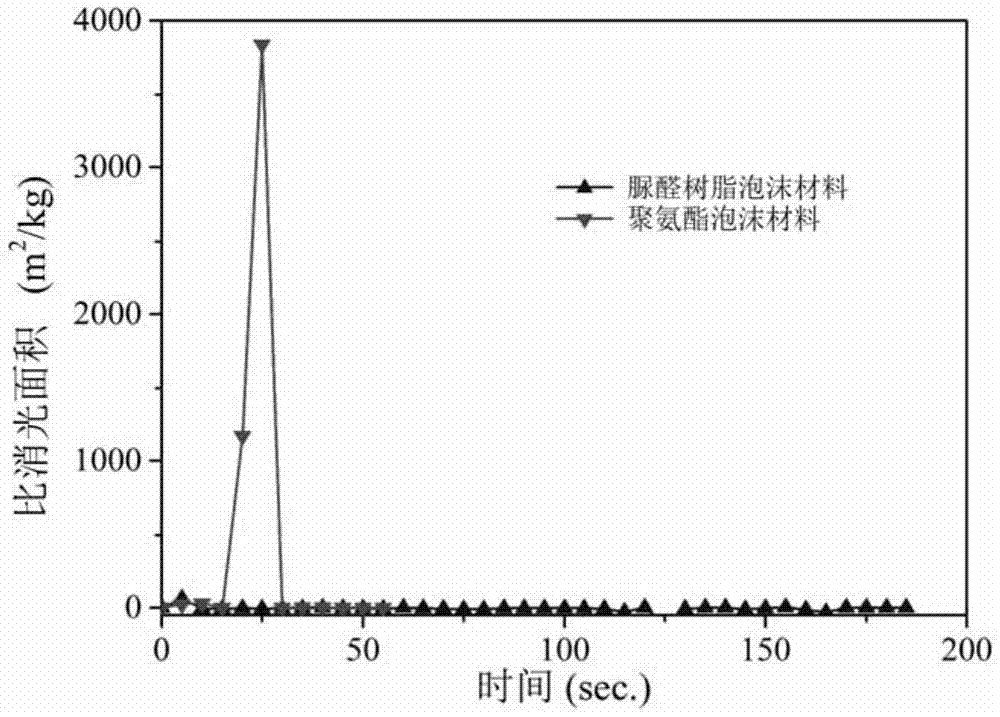

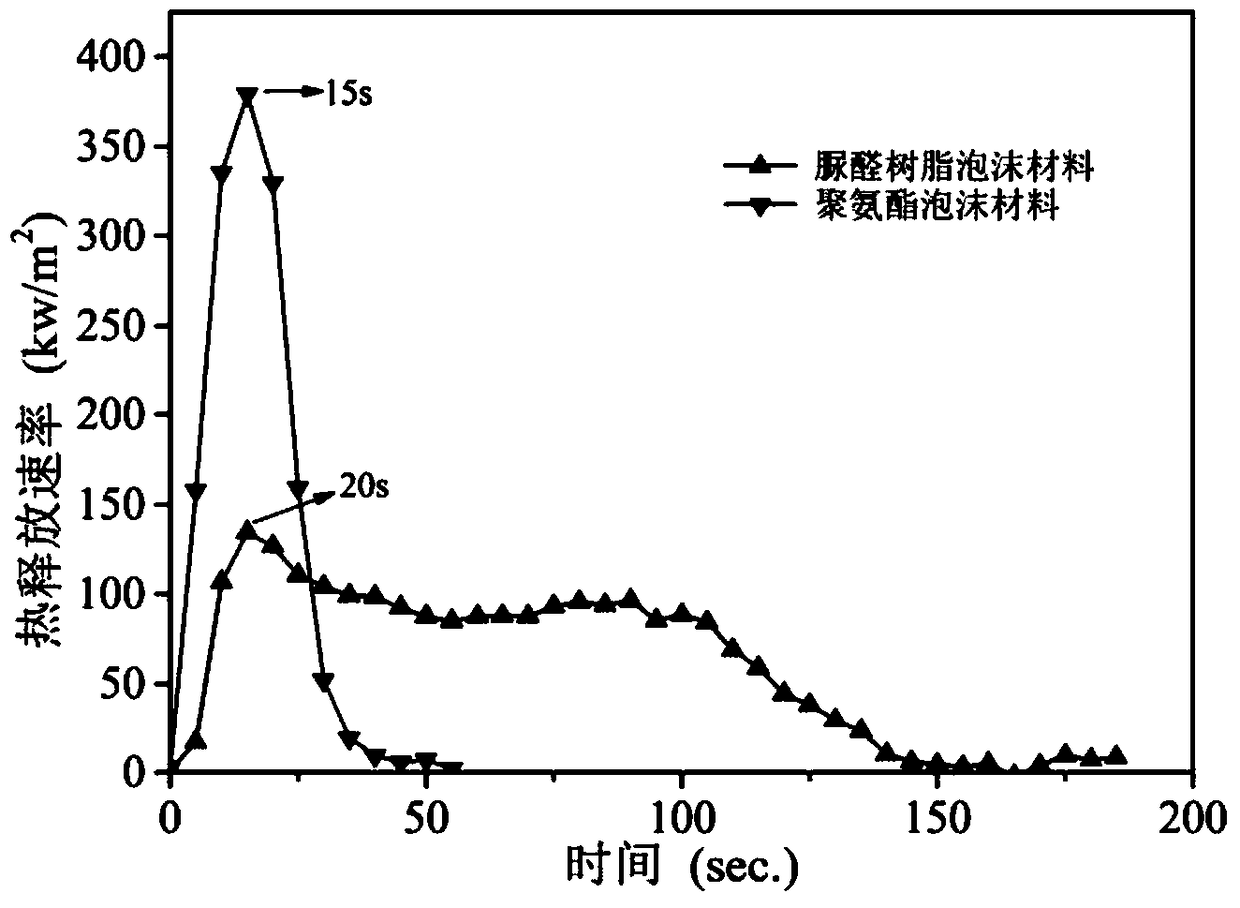

Flame-retardant hard polyurethane foam material with expanded graphite in synergy with phosphorous-containing flame retardant, and preparation method thereof

InactiveCN106279606AHave synergistic effectImprove flame retardant performanceFoaming agentCombustion

The invention relates to a flame-retardant hard polyurethane foam material with expanded graphite in synergy with phosphorous-containing flame retardant, made from, by weight, 100 parts of polyether polyol, 158-173 parts of isocyanate, 20-40 parts of DHDOPO (dihydroxy-containing DOPO), 15-25 parts of expanded graphite, 20-25 parts of a foaming agent, 2-5 parts of a foam stabilizer, and 1-1.5 parts of a catalyst; a preparation method of the flame-retardant hard polyurethane foam material with expanded graphite in synergy with phosphorous-containing flame retardant comprises the steps of preparing reactive flame retardant DHDOPO and preparing hard polyurethane foam. The invention has the advantages the phosphorus-containing flame retardant and the expanded graphite may cooperate to retard flaming, retarding effect is good, smoke production by combustion is low, and the retarding effect is permanent.

Owner:CHANGZHOU UNIV

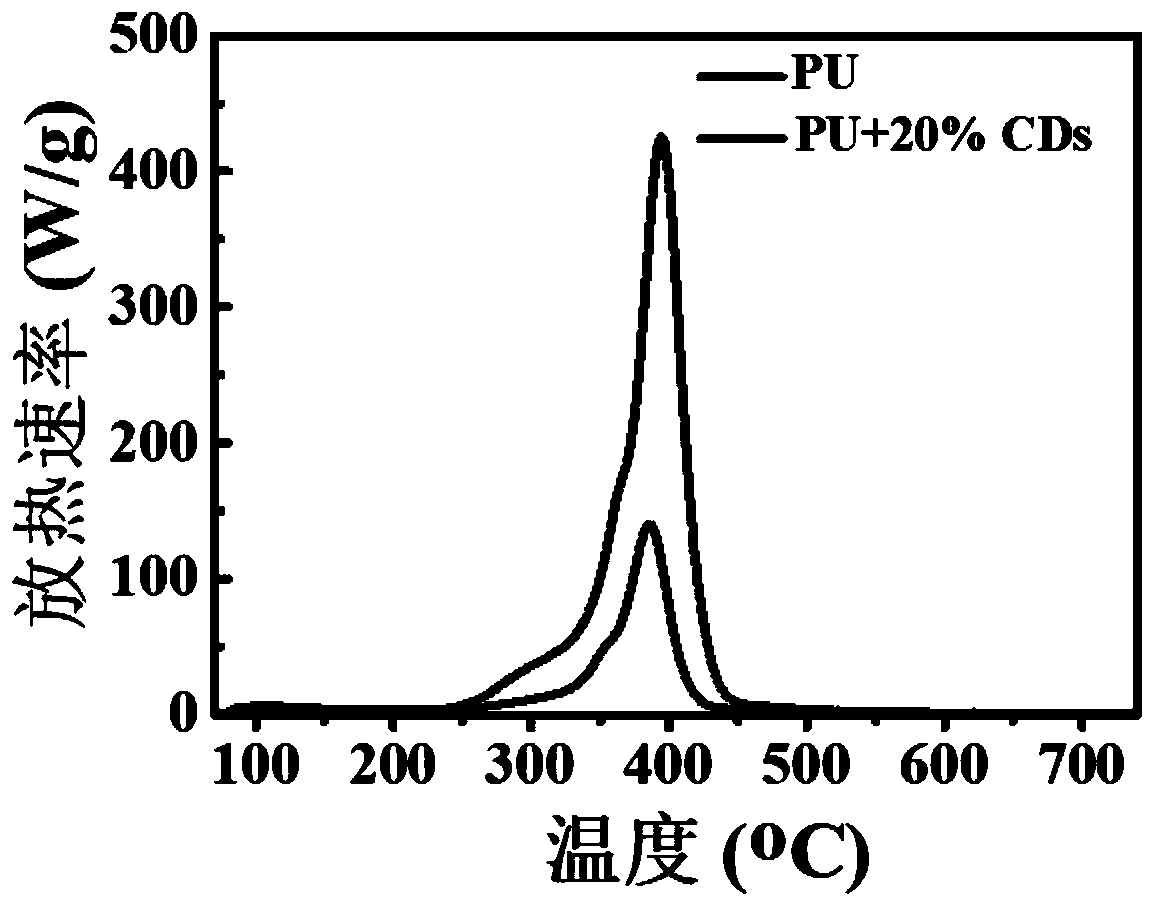

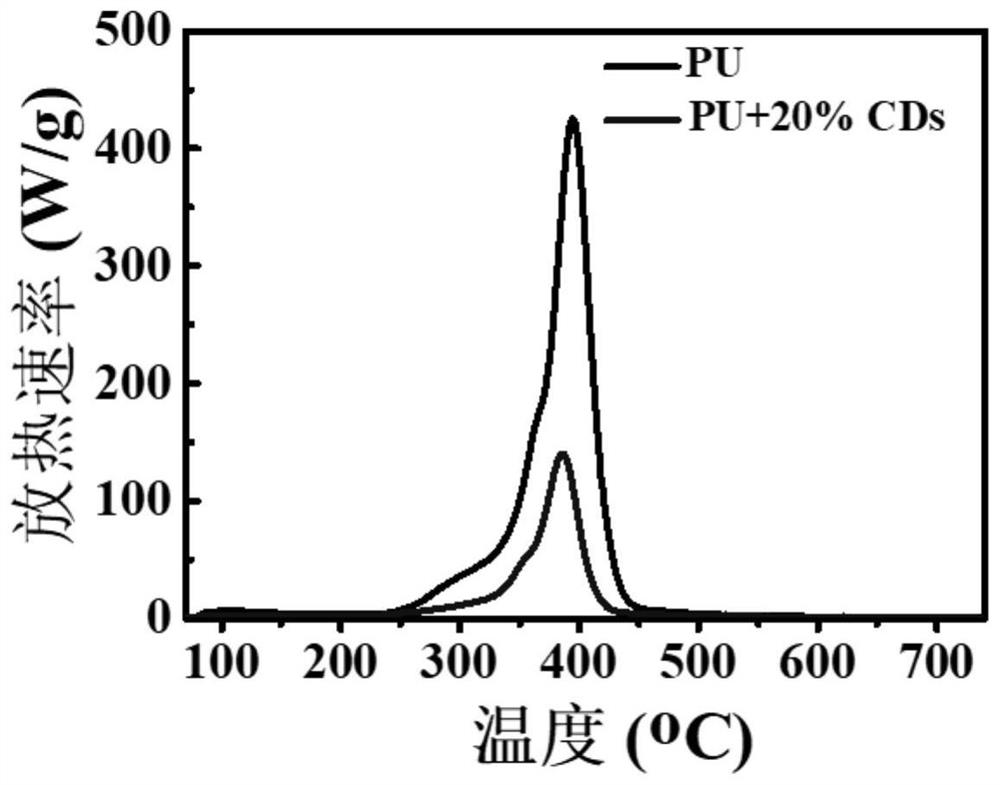

Carbon quantum dot-polymer composite material, and preparation method and application thereof

The invention discloses a carbon quantum dot-polymer resin composite material, and a preparation method and an application thereof. The carbon quantum dot-polymer resin composite material is a composite material prepared from carbon quantum dots and a polymer resin material through melt blending, wherein a mass ratio of the carbon quantum dots to the polymer resin material is 1:(2.3-10). The invention also discloses an application of the carbon quantum dot-polymer resin composite material in different fields. The carbon quantum dot-polymer resin composite material has the advantages of simplicity in operation, mild conditions, and easiness in large-scale preparation. The flame retardant application of the carbon quantum dots as a green halogen-free flame retardant in polymers is disclosedfor the first time. The carbon quantum dot-polymer resin composite material has the advantages of good flame retardant effect, greenness, environmental protection and the like, and provides a new ideafor the preparation of brand new environmentally-friendly halogen-free flame retardants.

Owner:NANJING UNIV OF TECH

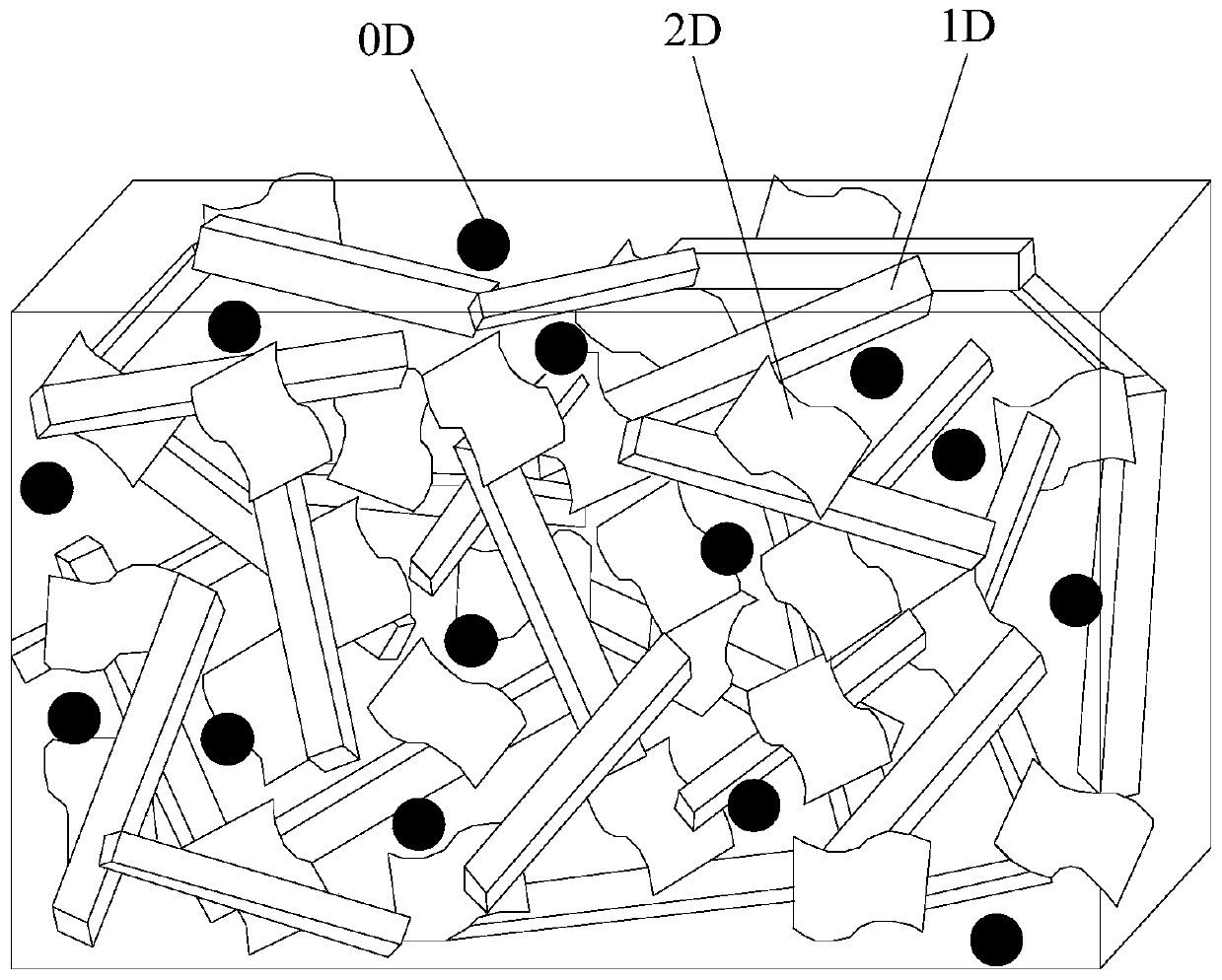

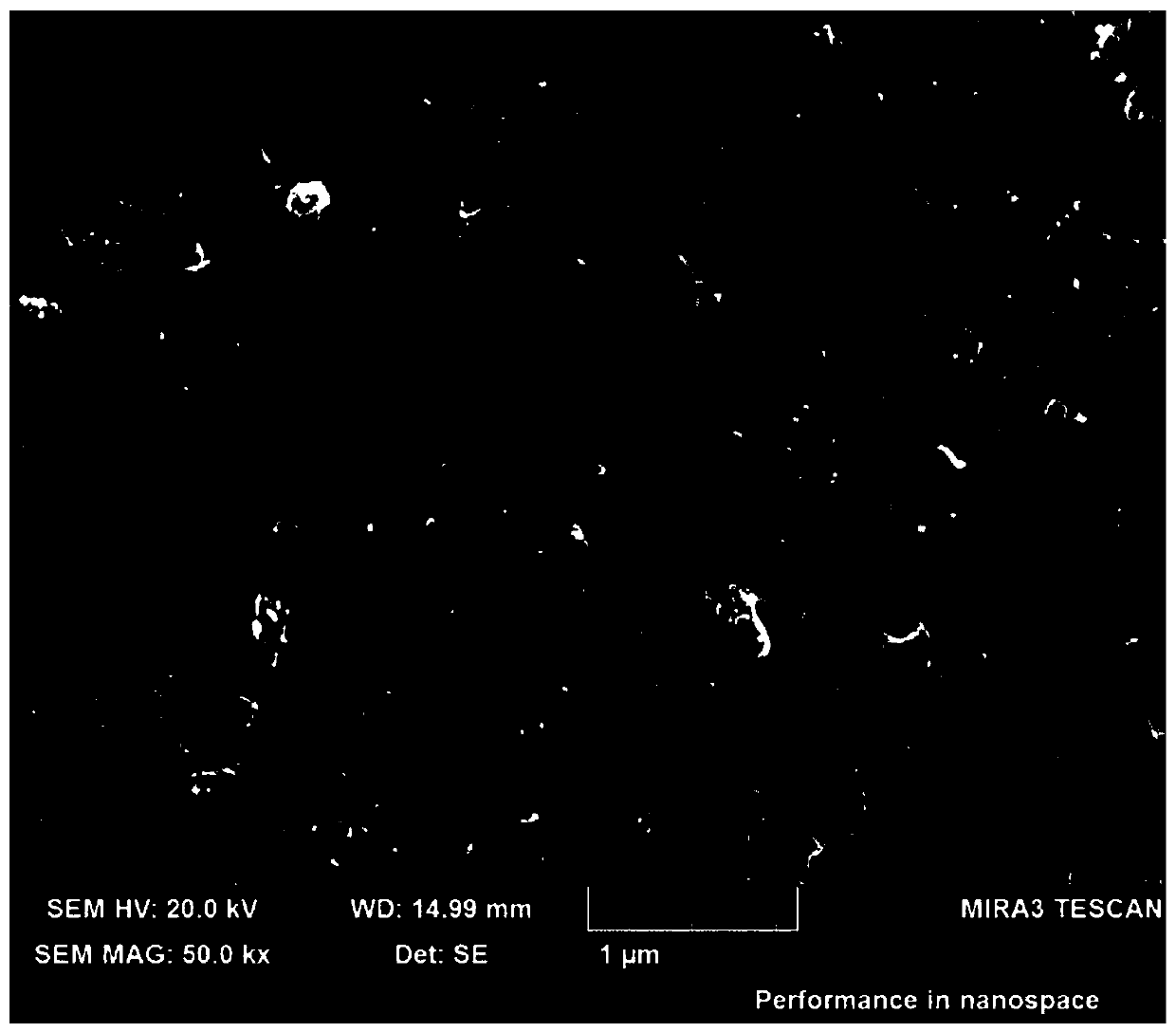

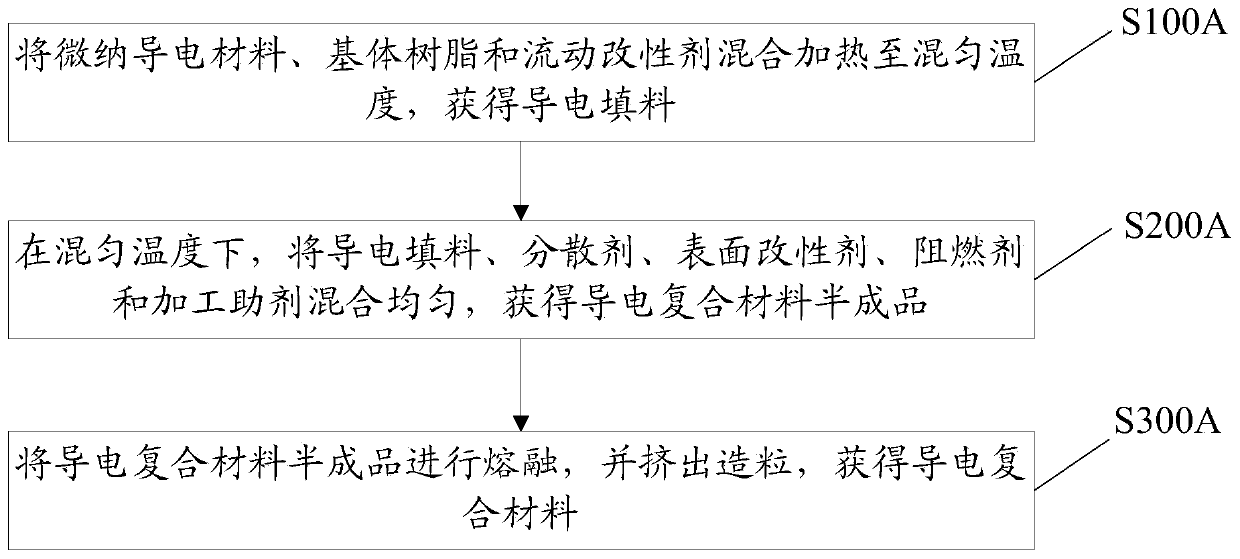

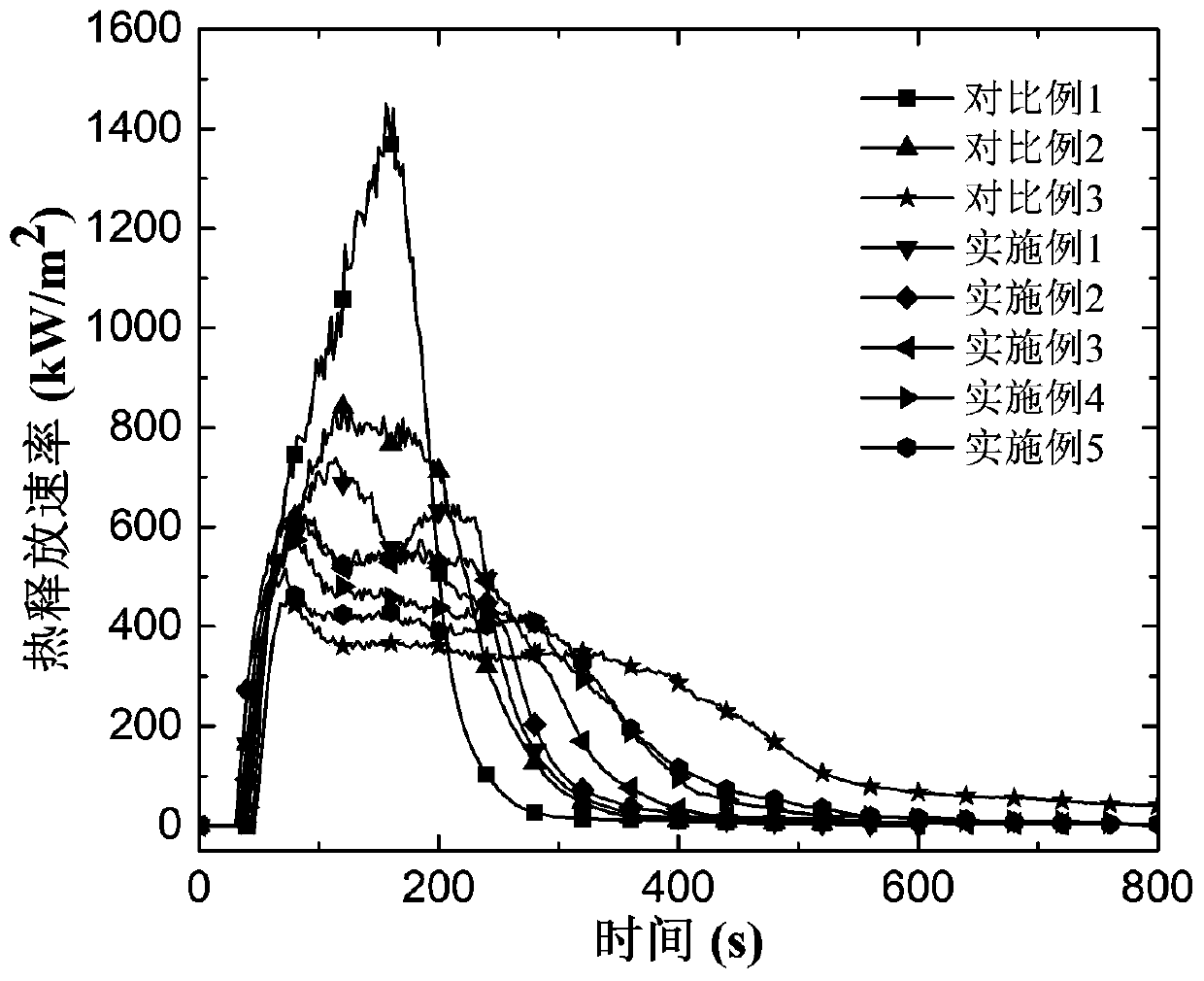

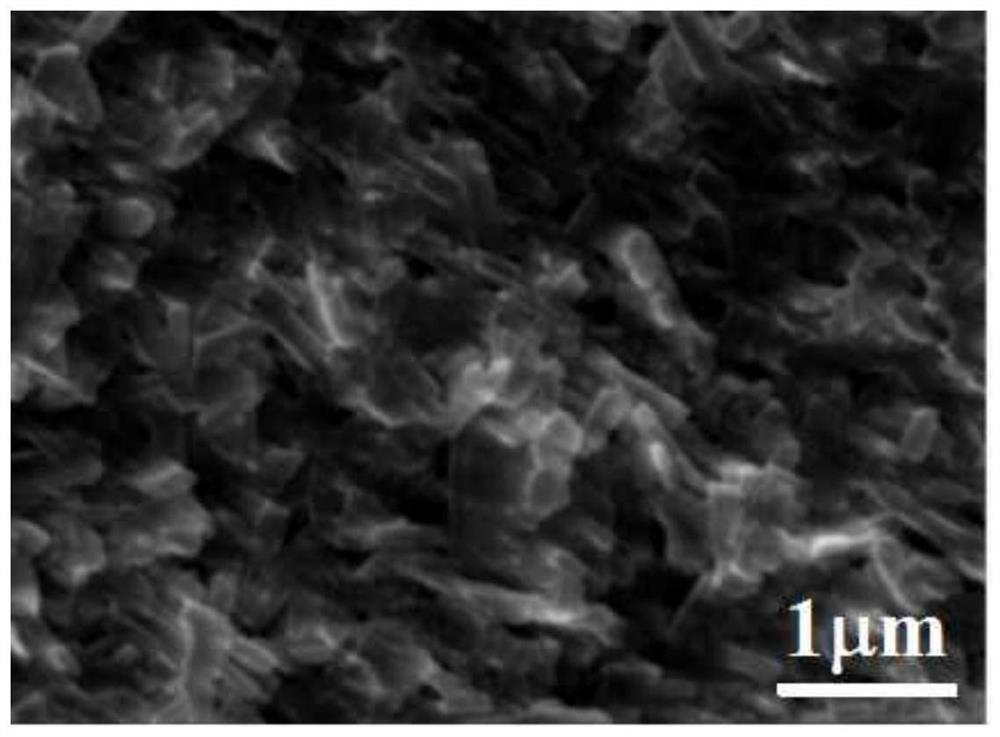

Conductive additive and application, conductive composite material and preparation method and application thereof

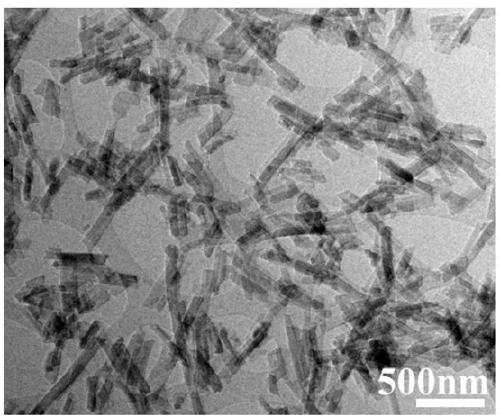

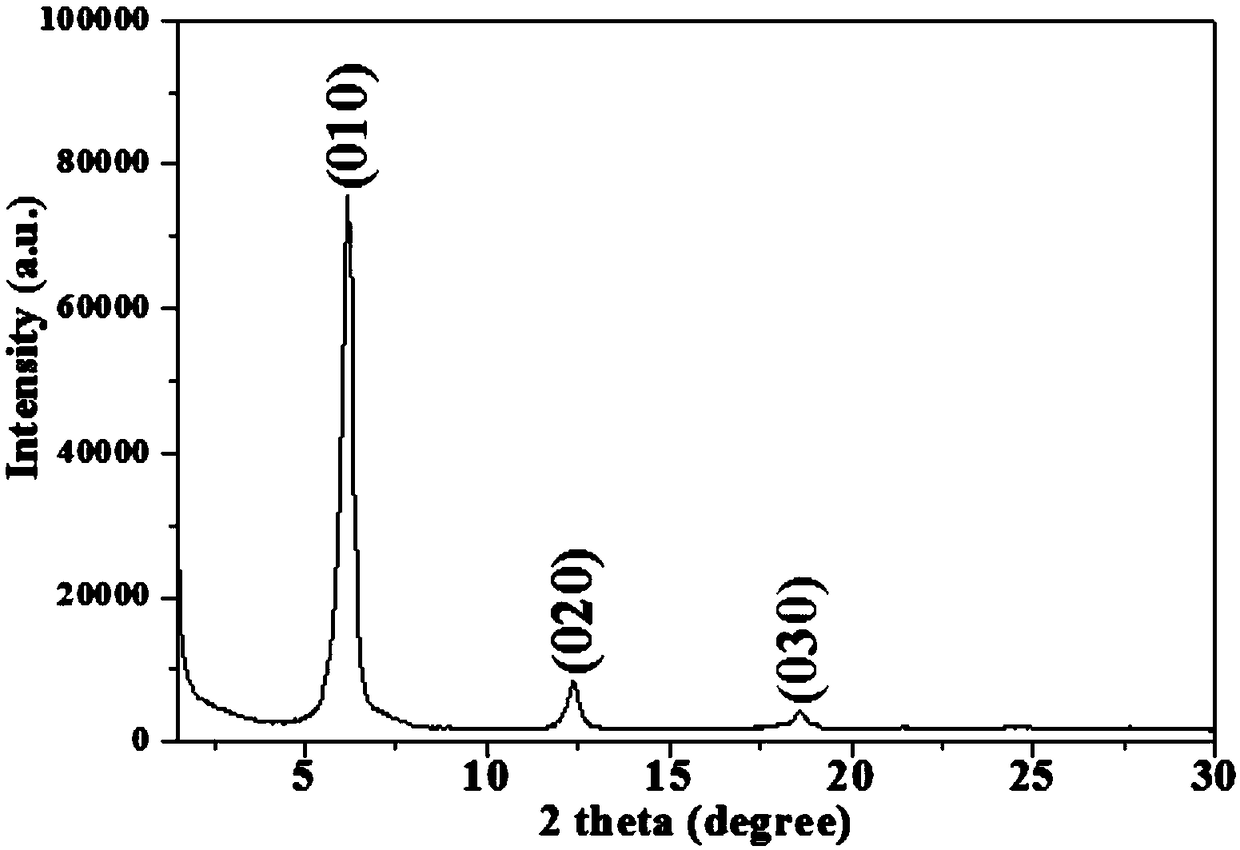

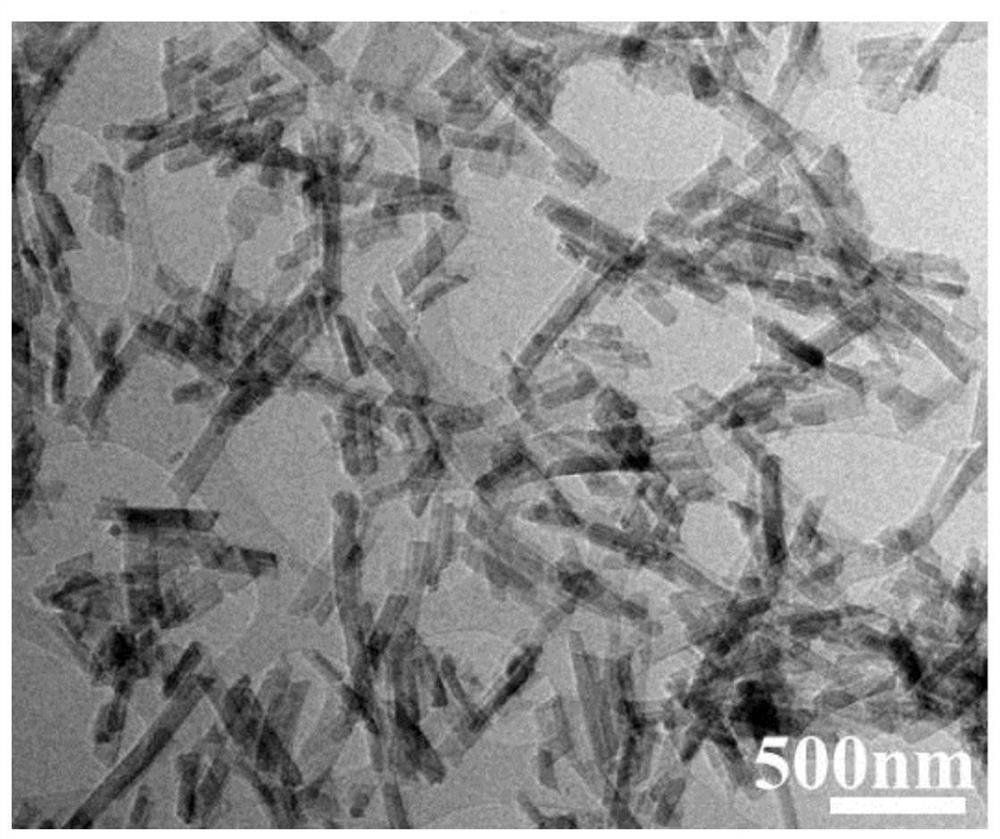

InactiveCN110511429ADoes not affect mechanical propertiesAchieving spatial complementarityMicro nanoConductive polymer composite

The invention discloses a conductive additive and application, a conductive polymer composite material and a preparation method and application thereof, relates to the technical field of polymer nanocomposite materials, and aims to improve the mechanical strength of the conductive composite material and reduce the flammability and melting rate of the conductive composite material. The conductiveadditive at least comprises micro-nano hybrid conductive materials, and the micro-nano conductive materials comprise zero-dimensional conductive materials, one-dimensional conductive materials and two-dimensional conductive materials. The conductive composite material comprises the conductive additive. The conductive additive is used in conductive polymer products.

Owner:内蒙古信敏惠纳米科技有限公司

Flame-retardant high-impact polystyrene composite material and preparation method thereof

The invention provides a flame-retardant high-impact polystyrene composite material and a preparation method thereof. The flame-retardant high-impact polystyrene composite material comprises the following components in parts by mass: 85 parts of high-impact polystyrene, 3-15 parts of a modified phosphorus-based flame retardant, and 3-15 parts of a nano flame retardant. Wherein the modified phosphorus-based flame retardant is a silane coupling agent modified phosphorus-based flame retardant, and the mass ratio of the silane coupling agent to the phosphorus-based flame retardant is (2-7): 100. The phosphorus-containing flame retardant and the nano flame retardant have a synergistic effect in flame retardant effect, so that the flame retardant property of the composite flame retardant can beimproved, and the flame retardant property of the high-impact polystyrene composite material is enhanced. The preparation method is simple in process flow, wide in raw material source, non-toxic, harmless, green and environment-friendly, and has a good application prospect.

Owner:NANJING UNIV OF TECH

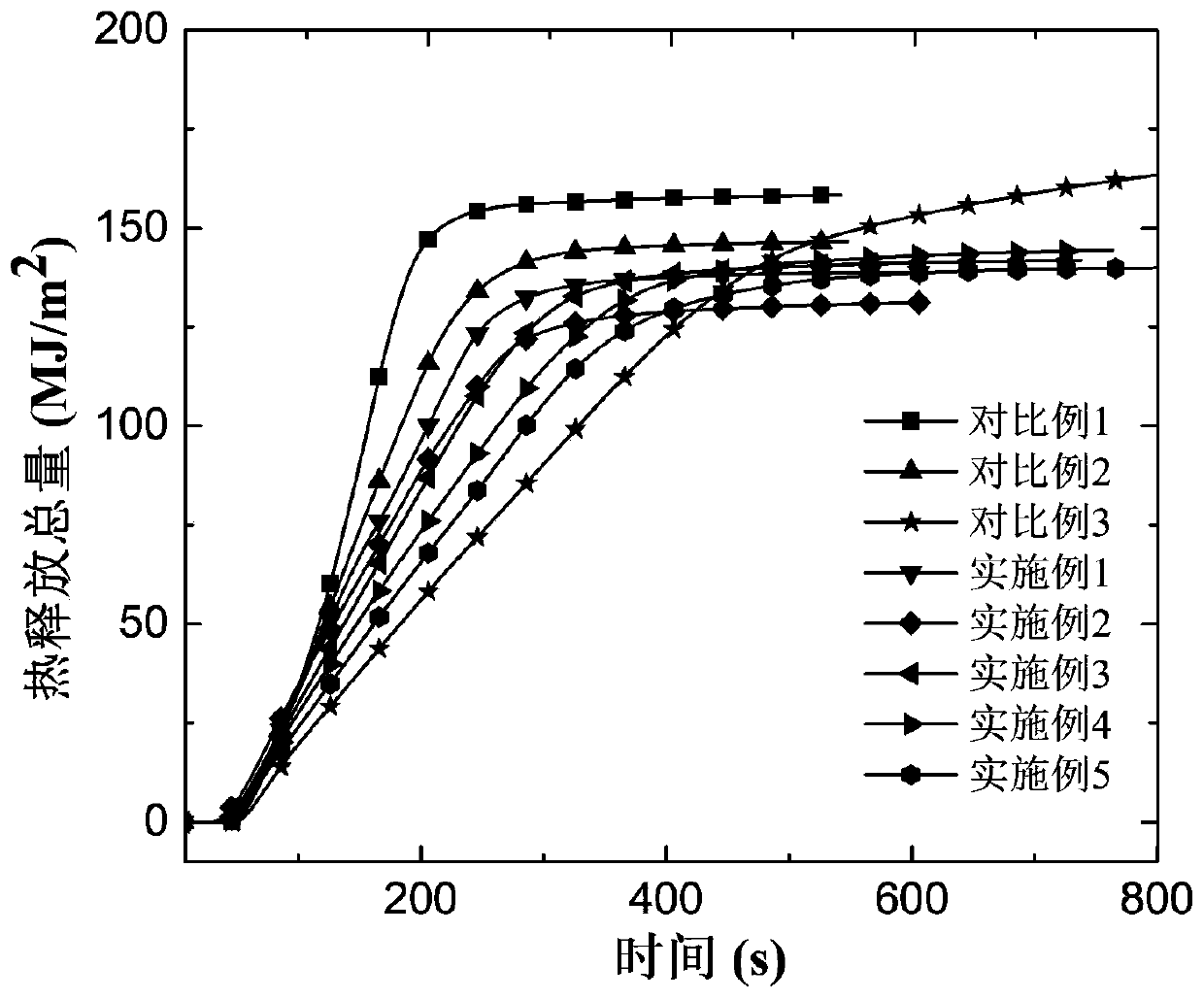

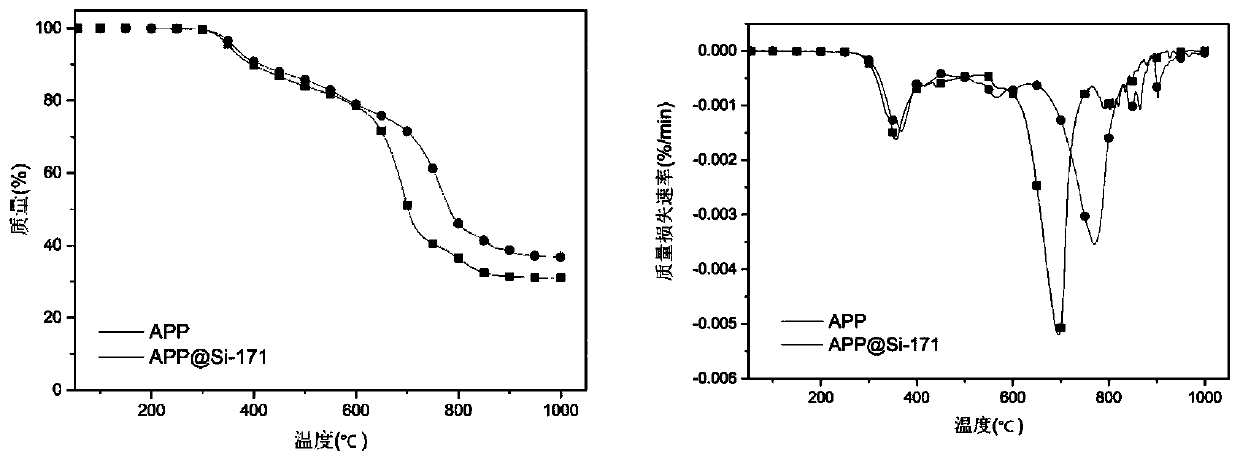

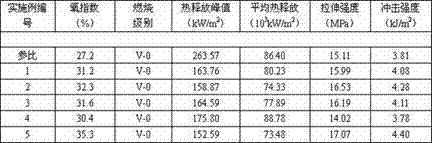

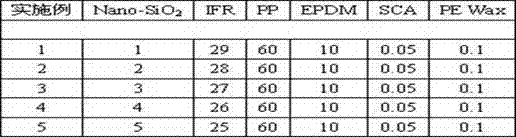

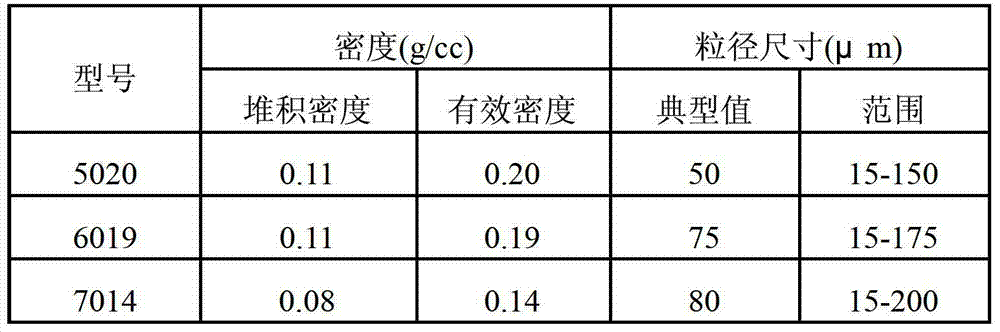

Nano silicon dioxide and intumescent flame retardant synergistic flame-resistance polypropylene/ethylene propylene diene monomer rubber composite material and preparation method thereof

InactiveCN107022147AHigh flame retardant efficiencyImprove mechanical propertiesPolymer scienceEthylene-propylene-diene-monomer

The invention discloses a nano silicon dioxide and intumescent flame retardant synergistic flame-resistance polypropylene / ethylene propylene diene monomer rubber composite material and a preparation method thereof. In parts by weight, a formula of the composite material consists of: 1 to 5 parts of nano silicon dioxide, 20 to 30 parts of intumescent flame retardant, 0.1 to 1.0 part of silane coupling agent, 50 to 70 parts of polypropylene, 5 to 15 parts of ethylene propylene diene monomer rubber, and 0.1 to 0.2 part of oxidized polyethlene wax. In the preparing process, the nano silicon dioxide and the intumescent flame retardant are surface-modified by the silane coupling agent. The surface-modified synergistic flame retardant is mixed with polypropylene / ethylene propylene diene monomer rubber and the like, and mixing and granulation are carried out by utilizing a three-screw extruder to prepare the nano silicon dioxide and intumescent flame retardant synergistic flame-resistance polypropylene / ethylene propylene diene monomer rubber composite material. The nano silicon dioxide provided by the invention not only can obviously improve flame retardant efficiency of the intumescent flame retardant for polypropylene / ethylene propylene diene monomer rubber alloy, but also greatly promotes mechanical performance of the intumescent flame retardant composite material.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

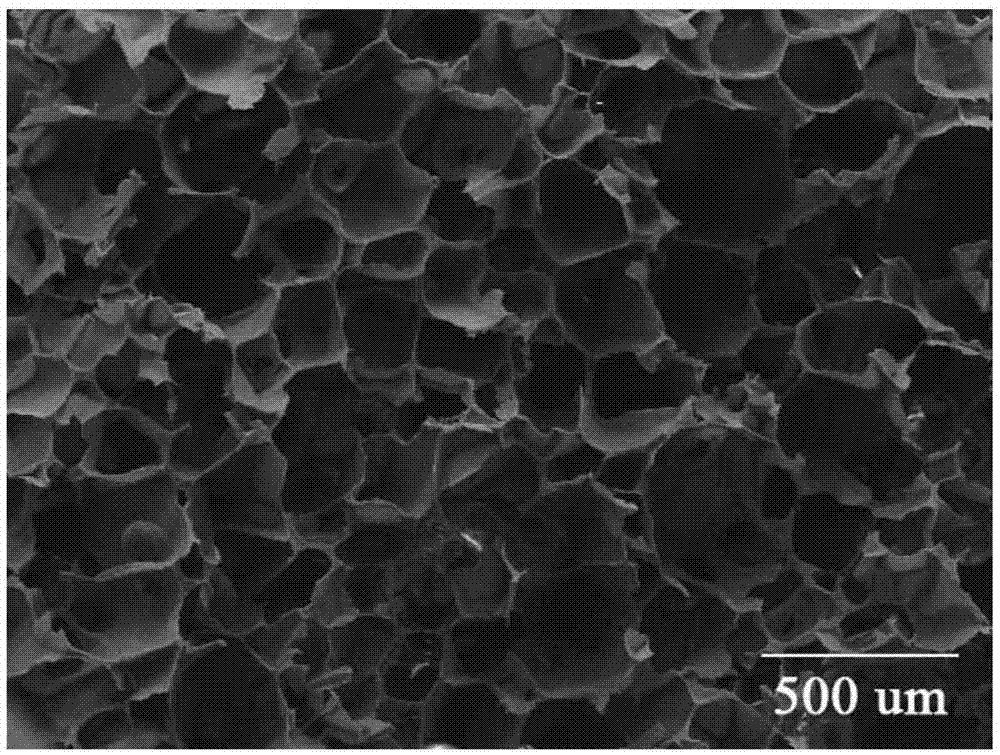

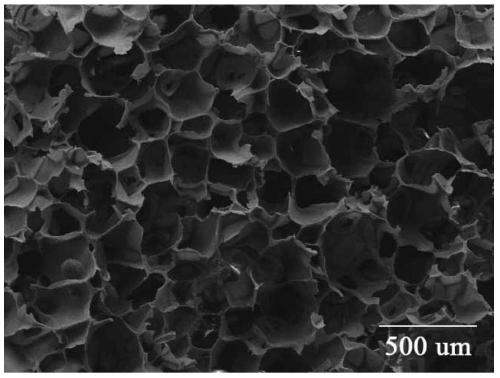

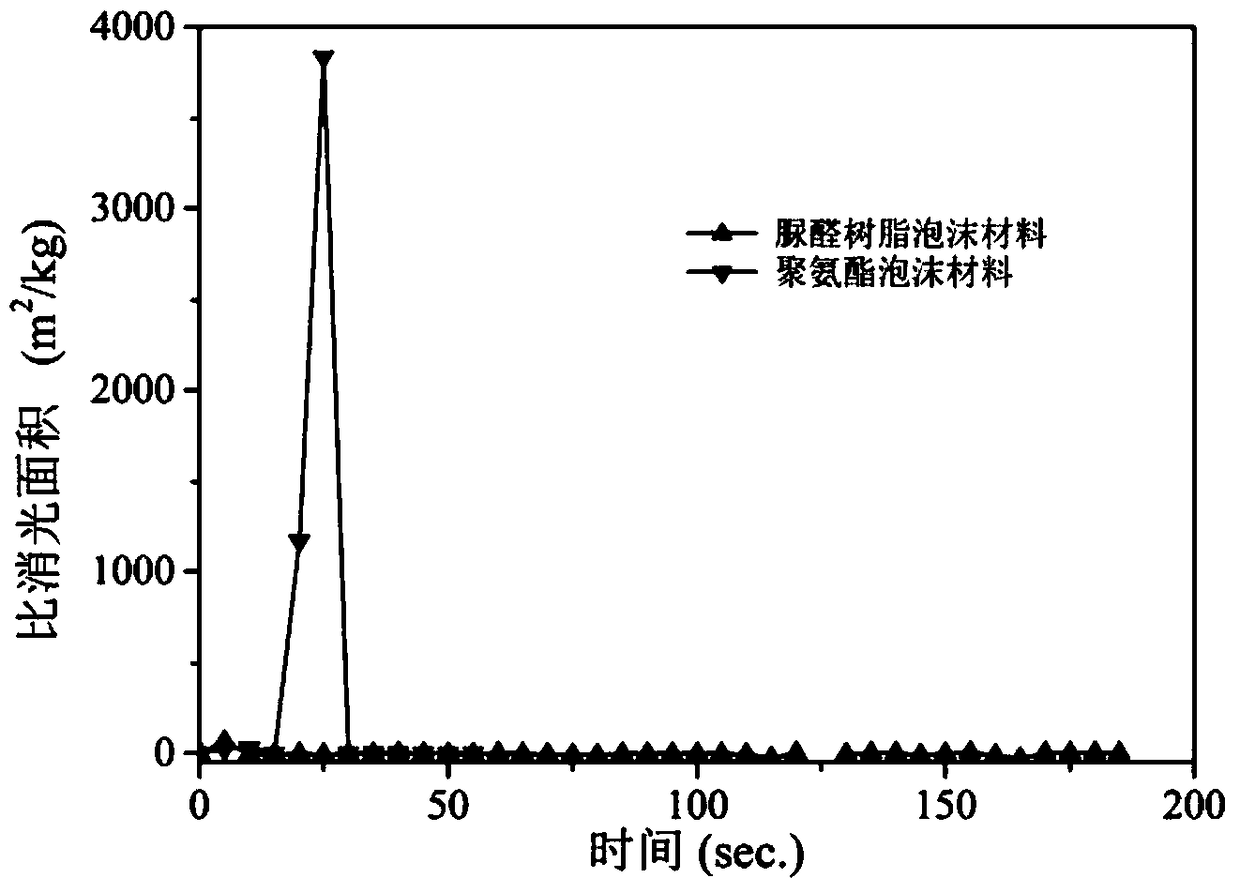

Strength/toughness-modified urea formaldehyde resin foam thermal-insulation material and preparation method thereof

The invention discloses a strength / toughness-modified urea formaldehyde resin foam thermal-insulation material and a preparation method thereof. The urea formaldehyde resin foam material is prepared from the following raw materials in percentage by weight: 80-97% of urea formaldehyde resin, 0.1-3% parts of foaming agent, 0.5-4% of surfactant, 0.1-1% of thickener, 0.1-1.5% of curing agent and 0.1-10% of modifier. The urea formaldehyde resin is synthesized by a three-step method; and the modifier can be added in the urea formaldehyde resin synthesis and foam emulsion preparation process. By adopting the physical foaming method, the uniform and stable foam emulsion is firstly prepared, and then, the foam emulsion is freely expanded in an open container. The strength / toughness-modified urea formaldehyde resin foam thermal-insulation material has the advantages of simple technique, low cost, favorable flame retardancy, small heat conductivity coefficient and small fire hazard coefficient, and can be applied to the field of building thermal-insulation materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of epoxy resin/iron phenyl phosphate composite

ActiveCN109486105AImprove flame retardant performanceHigh smoke suppression effectEpoxyHexamethylenetetramine

The invention belongs to the field of new materials and particularly discloses a preparation method of epoxy resin / iron phenyl phosphate composite. The preparation method includes: adding phenyl phosphoric acid, iron nitrate, polyvinylpyrrolidone and hexamethylenetetramine into a mixed solvent of ethanol, ethylene glycol and water to obtain FePP nanosheets; mixing the FePP nanosheets with epoxy resin L20, heating by oil bath, adding a curing agent, dissolving, vacuumizing to remove bubbles, and solidifying in staged manner to obtain epoxy resin / iron phenyl phosphate composite. Combustion performance results show that when the addition of the FePP nanosheets reaches 4% by weight, oxygen index increases to 35.1, reaching V-1 level (t1+t2 equals 15 s), heat release rate peak is 42.6% less than that of pure epoxy resin, and heat release total quantity decreases by about 26.3%; additionally, smoke release total quantity decreases by 32.8%, and CO release quantity decreases by 50.0%. The preparation method herein is simple and feasible, the epoxy resin / iron phenyl phosphate composite has excellent flame retardance and smoke-inhibiting efficiency and is applicable to flame-retardant protection for the matrix materials, such as foam, plastics, and rubber.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

High-efficient, environmentally-friendly, anti-corrosion and waterproof coating for subway shield segment and preparation method thereof

InactiveCN107964320AHigh antibacterial rateHas a synergistic antibacterial effectFireproof paintsAntifouling/underwater paintsEnvironmental resistanceSilicon dioxide

The invention provides a high-efficient, environmentally-friendly, anti-corrosion and waterproof coating for a subway shield segment and a preparation method thereof and relates to the technical fieldof coatings. The coating is prepared from a material A: 35 to 50 parts by weight of modified epoxy resin, 5 to 10 parts by weight of nano-zinc oxide, 5 to 8 parts by weight of chitosan, 15 to 20 parts by weight of nanometer light calcium carbonate, 10 to 15 parts by weight of nano-silica, 20 to 35 parts by weight of a styrene-acrylic emulsion, 15 to 25 parts by weight of titanium dioxide, 0.5 to1 part by weight of paraffin, 0.5 to 1 part of calcium stearate, 5 to 12 parts by weight of silicone oil, 3 to 5 parts by weight of polyacrylic acid, 5 to 8 parts by weight of texanol, 5 to 7 parts byweight of disodium EDTA, 3 to 5 parts by weight of sorbic acid, 5 to 10 parts by weight of cassia bark extract and 3 to 8 parts by weight of a flame retardant. The coating has the characteristics ofstrong weather resistance and low use cost and is waterproof, efficient, anticorrosion and environmentally friendly.

Owner:合肥卓立雅工程材料科技有限公司

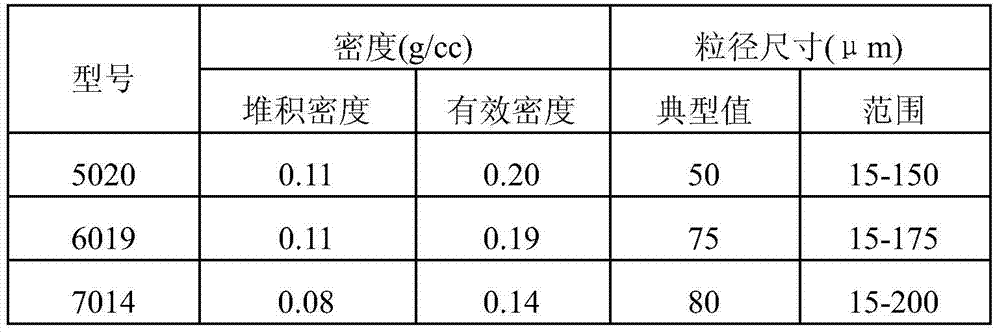

Application of homogeneous A2-grade polyurethane foam in thermal insulation material and preparation process of homogeneous A2-grade polyurethane foam

ActiveCN112679938AImprove thermal conductivityGood dimensional stabilityPolymer scienceInorganic particle

The invention relates to the technical field of polyurethane foam, and in particular, relates to an application of homogeneous A2-grade polyurethane foam in a thermal insulation material and a preparation process of the homogeneous A2-grade polyurethane foam. The homogeneous A2-grade polyurethane foam is mainly prepared from a component A, a component B and a component C according to a weight ratio of (5.4-10.3):(4.5-6.7):(80-90); the component A is prepared by mixing the following raw materials in parts by weight: 80-88 parts of urethane combined polyether, 9-14 parts of a toughening agent, 1-2 parts of an opening agent, 1-2 parts of a smoke suppressant and 1-2 parts of a light stabilizer; the component B is prepared by mixing the following raw materials in parts by weight: 65-85 parts of polymethylene polyphenyl isocyanate and 20-30 parts of a diisocyanate monomer; and the component C is a modified inorganic particle filler. The combustion performance of the polyurethane foam reaches A2 level, the advantages of low heat conductivity coefficient, low water absorption, good dimensional stability and the like of rigid polyurethane foam are reserved, and the polyurethane foam can be widely applied to the field of thermal insulation materials.

Owner:WEIHAI YUNSHAN TECH

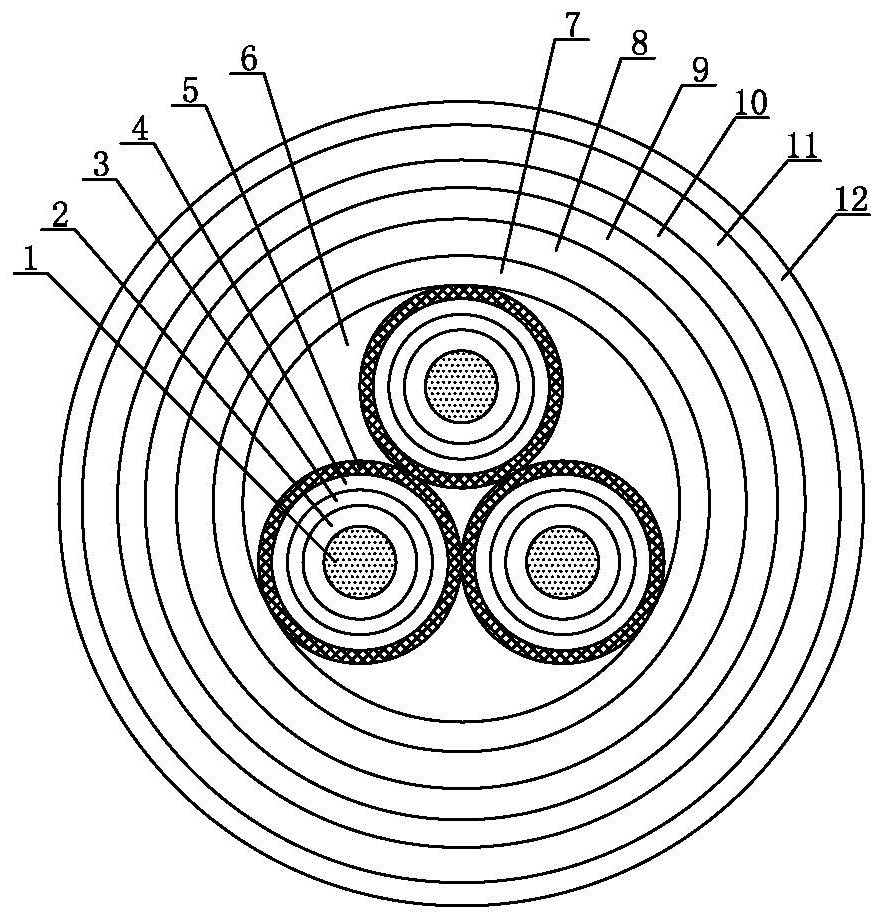

Jet flame and hydrocarbon flame resistant medium-voltage cable for offshore oil platform and manufacturing method thereof

ActiveCN112466536AEasy to slideSmall outer diameterClimate change adaptationInsulated cablesCopper conductorPolyolefin

The invention relates to a jet flame and hydrocarbon flame resistant medium-voltage cable for an offshore oil platform and a manufacturing method thereof. A semi-conductive conductor shielding layer,an insulating layer and a semi-conductive insulating shielding layer wrap the periphery of a stranded tin-plated annealed copper conductor from inside to outside in a three-layer co-extrusion mode; atinned copper wire shielding layer is woven on the periphery of a semi-conductive insulation shielding layer to form a shielding wire core, a plurality of shielding wire cores are twisted to form a cable core, an inner silicone oil layer is extruded on the periphery of the cable core, an inner lining layer is extruded on the periphery of the inner silicone oil layer, a fireproof wrapping tape is wrapped on the periphery of the inner lining layer, and an armor layer is wrapped on the periphery of the fireproof wrapping tape; the periphery of the armor layer is extruded with an outer silicone oil layer, the periphery of the outer silicone oil layer is extruded with a jet flame and hydrocarbon flame resistant inner sheath, and the periphery of the jet flame and hydrocarbon flame resistant inner sheath is extruded with a slurry resistant cross-linked polyolefin outer sheath. The cable adopts a double-layer composite sheath, can bear high-temperature flame of 1300 DEG C for 120 minutes under rated voltage, and does not have a grounding fault or a short circuit.

Owner:WUXI MINGZHU CABLE

Micro foam polystyrene group composite material of wood and plastic, and method of producing the same

A micro-foaming polystyrene wood-plastic composite material and a preparation method thereof, which relates to a micro foaming wood-plastic composite material and the preparation method thereof. The present invention solves the problems of poor impact resistance and easy combustion of the current wood-plastic composite material. The present invention is made of wood fiber material, coupling agent, plasticizer, lubricant, polystyrene, foamer, assistant foamer, fire retardants and smoke suppressant according to a weight portion. The preparation method is as follows: first, hot mixing; secondly,cooling and mixing; thirdly, extruding and molding. Then the micro-foaming polystyrene wood-plastic composite material can be made. The micro-foaming polystyrene wood-plastic composite material of the present invention has the advantages of small density, good fire-resistant and smoke-suppression effects, and impact resistance.

Owner:NORTHEAST FORESTRY UNIVERSITY

Modified amino resin expansion type aqueous flame-proof paint

InactiveCN101117510BImprove flame retardant performanceIncreased resistance to ignitionFireproof paintsEmulsion paintsPliabilityMelamine

The present invention relates to amino resin intumescent aqueous flame retardant coating, in particular to an intumescent aqueous flame retardant coating. The present invention eliminates the releaseof harmful organic volatile compounds of the inflaming-retardant coating in use, improving poor fire resistant performance of dewatering catalyst due to a high disassembling temperature, solving theproblems of long manufacturing period, low efficiency and high cost of the inflaming-retardant wood materials. The materials for the present invention comprises amino resin, polyvinyl acetal resin, dewatering catalyst, melamine, charring agents, dope assistant, antifoaming agent, palette filling and water. The present invention has storage for a long time, good cohesion, slow and low emission of heat and low emission of smoke, enjoying good flexibility and good strike-resistant performance; furthermore, the present invention can be manufactured easily and used conveniently and can be easily popularized without emission of harmful organic volatile in use. Compared with a prior wooden inflaming-retardant liquid, the present invention has the advantages of simple process, convenient operation, low cost and high efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY

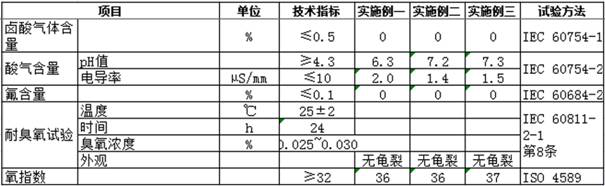

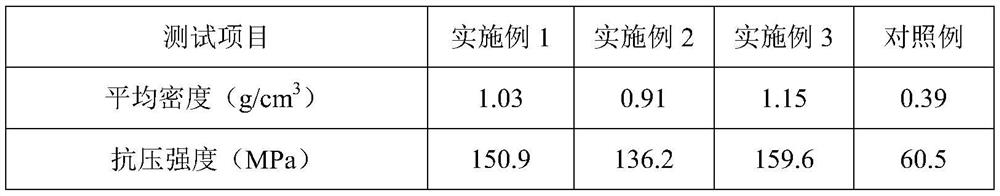

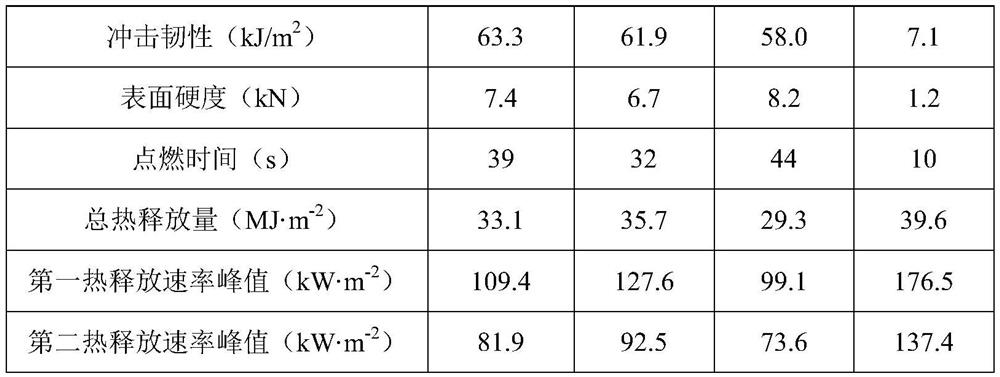

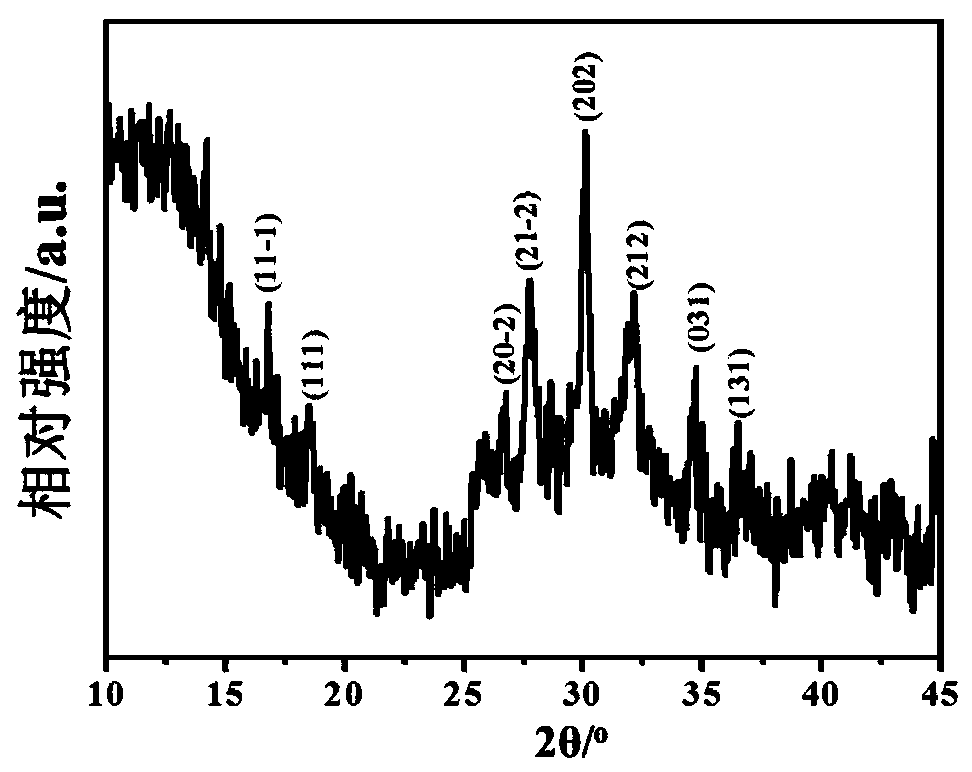

A kind of preparation method of silicate flame retardant dense wood

ActiveCN111037686BReduce spreadHigh densityPressure wood treatmentWood treatment detailsPulp and paper industryFormaldehyde free

The invention discloses a preparation method of silicate flame-retardant dense wood, and belongs to the technical field of preparation methods of flame-retardant dense wood. The invention forms a dense laminated wood structure through steps such as wood component removal, silicate infiltration, and high-temperature hot-pressing process. While improving the loss resistance of flame-retardant components, it completely solves the problem of free formaldehyde release and high brittleness of impregnated modified materials. , high cost and other issues, significantly improving the mechanical strength and flame retardant properties of wood. Moreover, the invention has low cost, simple process, no expensive resin synthesis device, low impregnation pressure, easy control, and short drying cycle; it is environmentally friendly, has no formaldehyde release, and reduces environmental pollution; and at the same time, it improves the strength, toughness and flame retardancy of wood performance. The invention has high reference value for the reinforcement-flame retardant modification of low-quality wood in plantation forests, and is suitable for popularization and application.

Owner:HENAN AGRICULTURAL UNIVERSITY

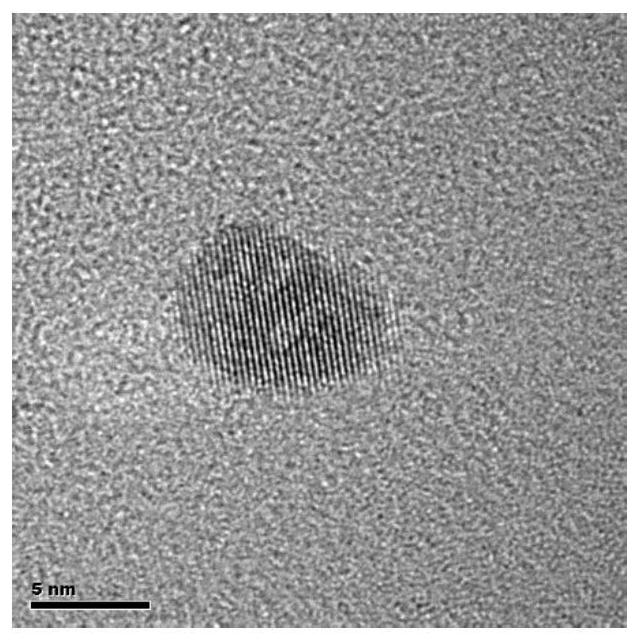

A kind of carbon quantum dot-polymer composite material and its preparation and application

The invention discloses a carbon quantum dot-polymer resin composite material as well as its preparation and application. Carbon quantum dot-polymer resin composite material is a composite material prepared by melt blending carbon quantum dots and polymer resin materials; wherein the mass ratio of carbon quantum dots to polymer resin materials is 1:(2.3~10). The invention discloses the application requirements of carbon quantum dot-polymer resin composite materials in different fields, and has the advantages of simple operation, mild conditions, and easy large-scale preparation; it discloses carbon quantum dots as a green halogen-free flame retardant for the first time The flame retardant application in polymers has the advantages of good flame retardant effect and environmental protection, and provides a new idea for the preparation of a new environmentally friendly halogen-free flame retardant.

Owner:NANJING TECH UNIV

Method for preparing carbon nanometer paper flame resistant polymer matrix composite material

InactiveCN103317785BImprove flame retardant propertiesShorten ignition timeGlass/slag layered productsToxic gasCombustion

The invention provides a method for preparing a carbon nanometer paper flame resistant polymer matrix composite material, which is intended to solve problems that: the current resin-based fiber reinforced composite materials exist unsafe factors of flammability, high combustion speed, difficult extinguishing, and environment pollution because of toxic gas generation; and addition of nano-materials like carbon nanotubes in a composite material can improves flame resistance of the composite material, but flame resistant and fireproof characteristics, and dispersibility and content of the nano-materials like carbon nanotubes affect integral mechanical properties of the composite material. The method comprises: adding at least one flame resistant material into a carbon nanometer paper structure, and then using the carbon nanometer paper structure as a flame resistant external layer of the composite material to form the carbon nanometer paper flame resistant polymer matrix composite material. The carbon nanometer paper flame resistant polymer matrix composite material has a good flame resistant characteristic, and a plurality of flame resistant materials is added into the carbon nanometer paper structure, thereby greatly raising flame resistant and fireproof characteristics of the composite material. Compared to a composite material without carbon nanometer paper, ignition time of the carbon nanometer paper flame resistant composite material can be reduced more than 10-30%, and a peak value of heat releasing speed can be reduced more than 15-45%, and a smoke releasing total amount can be reduced more than 10-30%.

Owner:SHENYANG AEROSPACE UNIVERSITY

Clean, flame-retardant and smoke-suppressing epoxy resin nanocomposite material and preparation method thereof

ActiveCN110564108AImprove flame retardant performanceHigh flame retardant efficiencyHalogenChemistry

The invention discloses a clean, flame-retardant and smoke-suppressing epoxy resin nanocomposite material and a preparation method thereof. The clean, flame-retardant and smoke-suppressing epoxy resinnanocomposite material is prepared by compounding a K2Co3(P2O7)2.2H2O nanomaterial flame retardant, an epoxy monomer, 4,4'-diaminodiphenylmethane, a curing agent and a curing agent. The epoxy resin nanocomposite material comprises, by mass, 1-12 wt% of the K2Co3(P2O7)2.2H2O nanomaterial, with the balance being a mixture of the epoxy monomer and 4,4'-diaminodiphenylmethane, wherein a mass ratio ofthe epoxy monomer to the 4,4'-diaminodiphenylmethane is 4: 1. Directed at the problems that conventional flame-retardant epoxy resin composite materials contain toxic elements such as halogen and ispoor in smoke suppression and mechanical performance, the invention provides the halogen-free K2Co3(P2O7)2.2H2O nanomaterial serving as a clean flame retardant, and the characteristics of cleanness,no pollution and good flame retardance and smoke suppression performance are obtained.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ZHENJIANG POWER SUPPLY CO

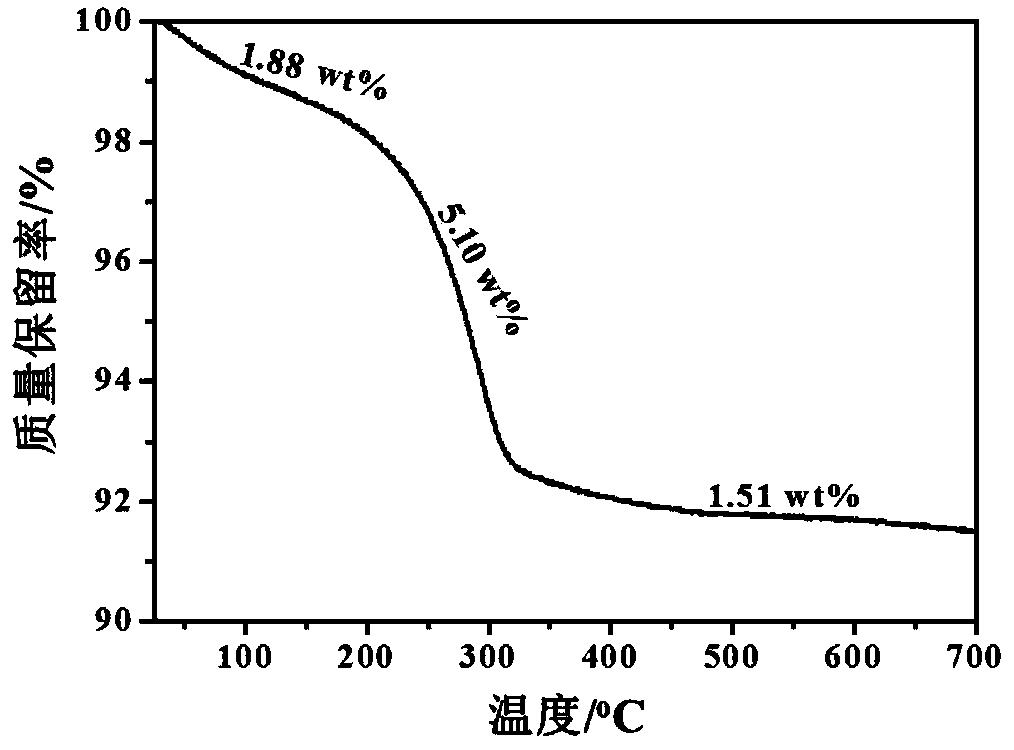

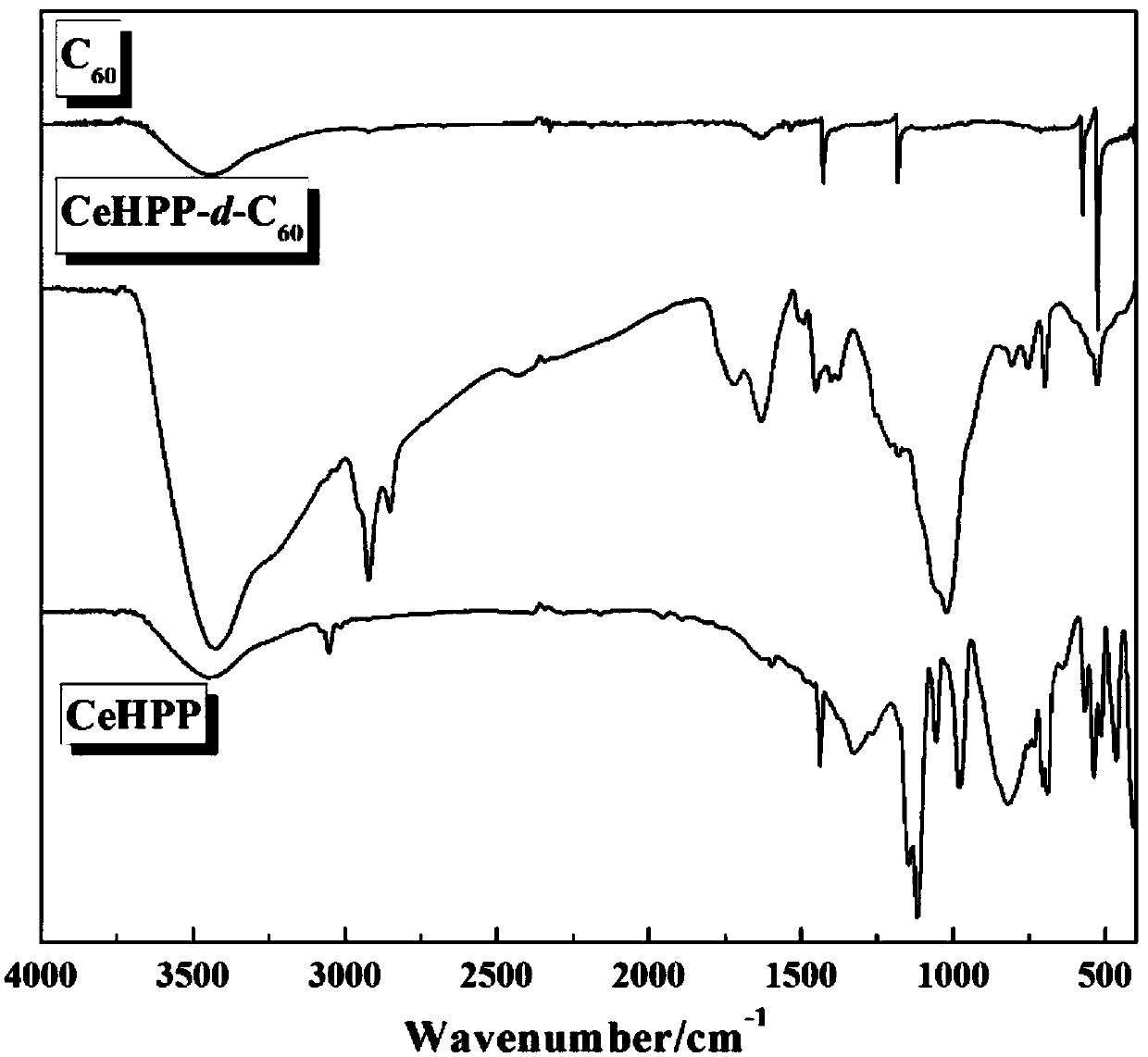

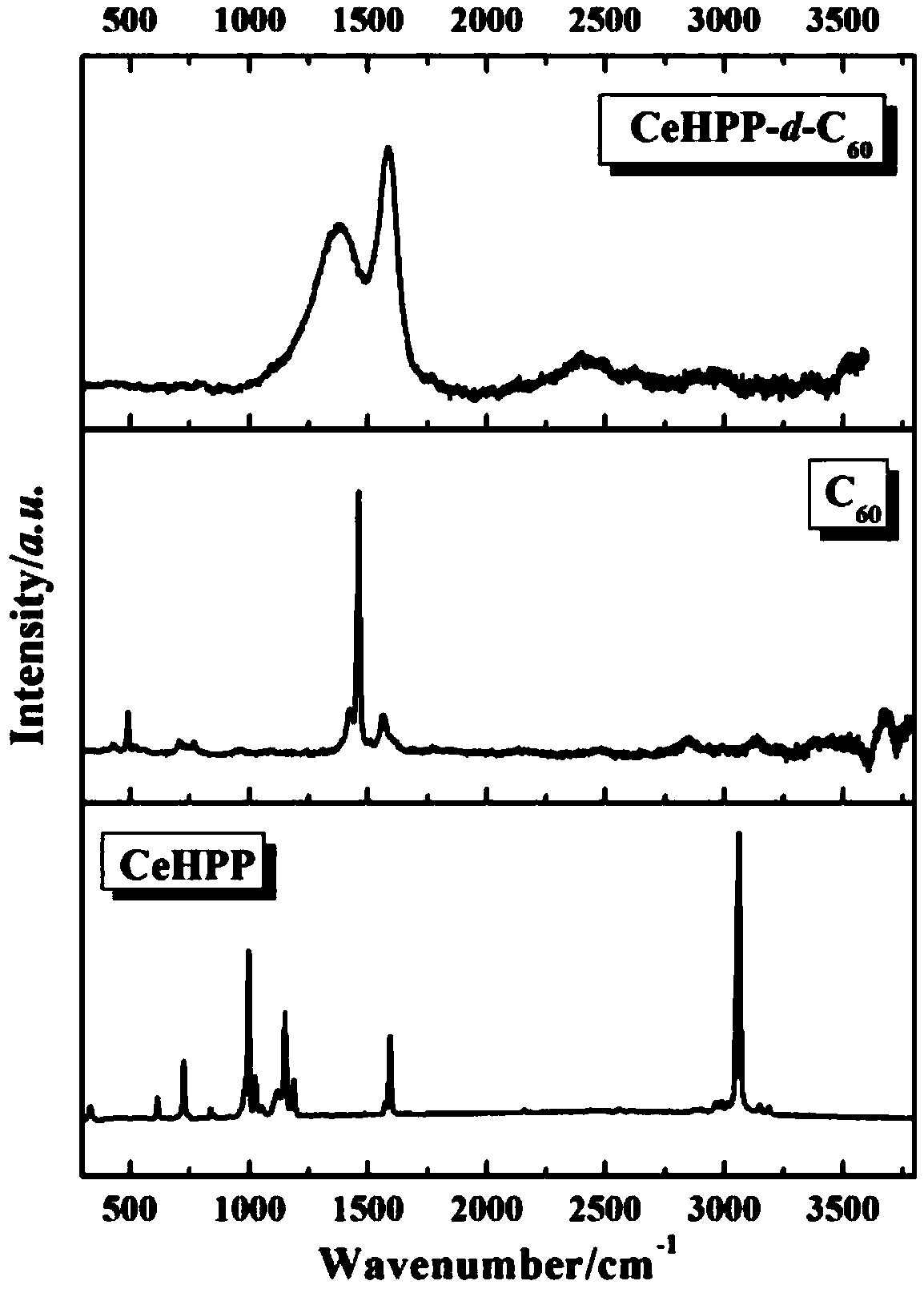

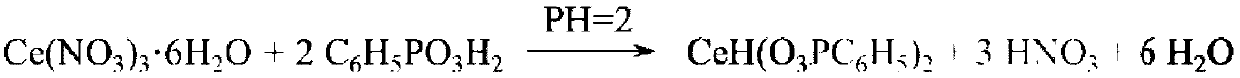

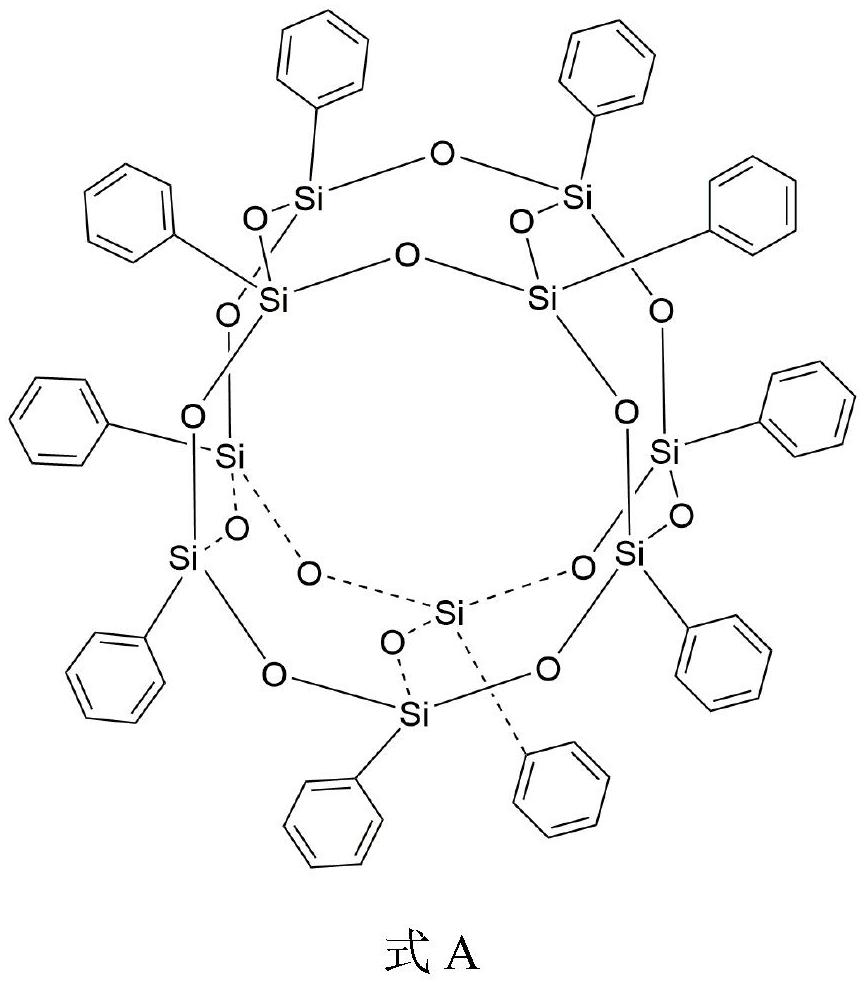

Fullerene-modified phenylphosphonic acid rare earth hybrid, polycarbonate composite material containing it and preparation method thereof

The invention discloses a fullerene-modified phenyl phosphonic acid rare-earth hybrid, a polycarbonate composite material containing the same and a preparation method of the fullerene-modified phenyl phosphonic acid rare-earth hybrid. The preparation method of the hybrid comprises the steps of dissolving fullerene into xylene to form a fullerene solution; mixing and dispersing a phenyl phosphonic acid rare-earth salt into the xylene to form a suspension liquid; dropwise adding the prepared solution into the suspension liquid and refluxing at a constant temperature of 65-95 DEG C or 18-24h; and carrying out suction filtration on a reaction solution after reflux reaction, washing and drying to constant weight to obtain solid particles, namely the fullerene-modified phenyl phosphonic acid rare-earth hybrid. The problem that heat and a combustible gas are greatly released within short time due to sudden collapse of the material under the high temperature action is solved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

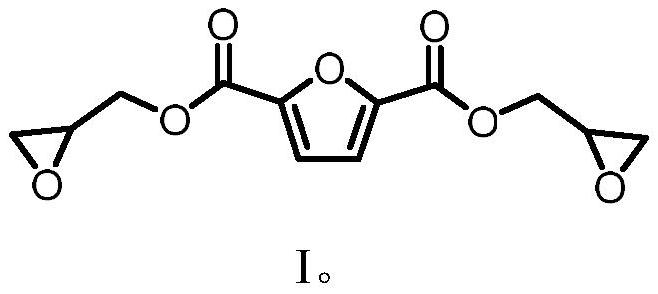

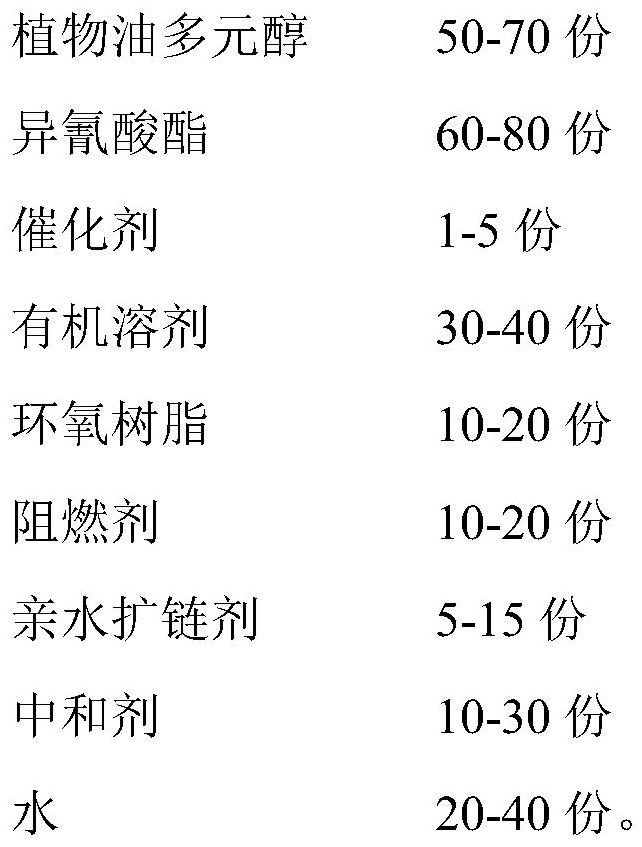

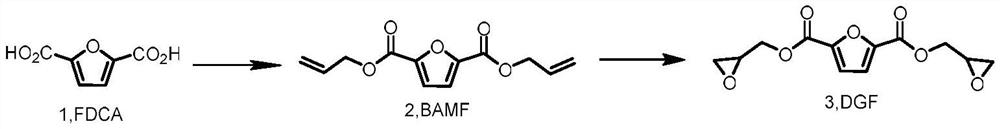

A kind of flame-retardant vegetable oil-based water-based polyurethane coating and preparation method thereof

ActiveCN112280459BGreenImprove water resistanceFireproof paintsPolyurea/polyurethane coatingsEpoxyVegetable oil

The invention discloses a flame-retardant vegetable oil-based water-based polyurethane coating and a preparation method thereof. Vegetable oil polyol, isocyanate, catalyst, organic solvent, epoxy resin, flame retardant, hydrophilic prepared from raw materials; wherein, the epoxy resin is a compound represented by formula I. The invention provides a method for preparing a flame-retardant vegetable oil-based water-based polyurethane coating. The preparation method is simple to operate, and the prepared polyurethane coating has excellent properties such as environmental protection, good water resistance, low product price, and good flame-retardant performance, which is beneficial to Industrial production.

Owner:NANJING TECH UNIV

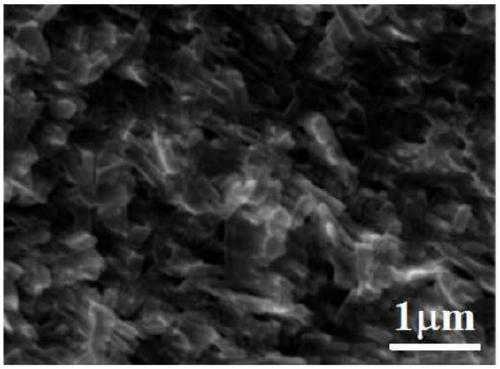

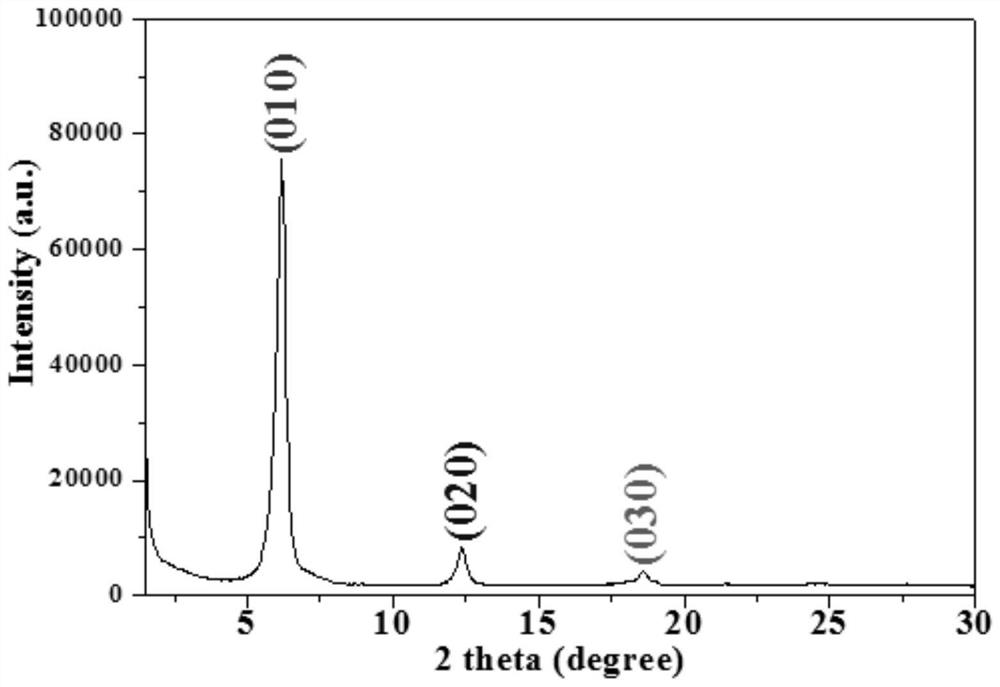

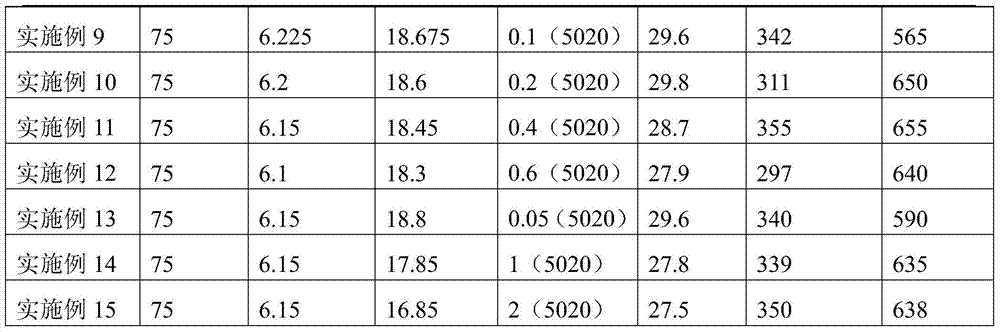

A kind of modified expandable graphite, flame retardant and its preparation method and application in polyurethane foam

The invention relates to the technical field of flame retardants, in particular to a modified expandable graphite, a flame retardant and its preparation method and its application in polyurethane foam, which is characterized in that one or more layers are adsorbed on the surface of the expandable graphite A polymer surface modifier with special functional groups, the preparation method of the modified expandable graphite includes: using an organic modifier containing a hydroxyl group and a polar six-membered ring structure to modify the surface of the expandable graphite, and adding a dispersant to mix The modified graphite can be obtained by crushing and sieving after uniformity. After the modified graphite is added to the polyurethane combination polyether in a certain proportion and mixed evenly, it can be uniformly dispersed and suspended in the polyether; and the flame retardant performance of the obtained polyurethane insulation material is Greatly improved and does not affect other properties of polyurethane rigid foam, it has the advantages of good flame retardant performance, long-lasting flame retardant effect, greatly improved oxygen index, and greatly reduced peak heat release rate.

Owner:WEIHAI YUNSHAN TECH

A kind of preparation method of epoxy resin/phenyl iron phosphate nanocomposite material

The invention belongs to the field of new materials and particularly discloses a preparation method of epoxy resin / iron phenyl phosphate composite. The preparation method includes: adding phenyl phosphoric acid, iron nitrate, polyvinylpyrrolidone and hexamethylenetetramine into a mixed solvent of ethanol, ethylene glycol and water to obtain FePP nanosheets; mixing the FePP nanosheets with epoxy resin L20, heating by oil bath, adding a curing agent, dissolving, vacuumizing to remove bubbles, and solidifying in staged manner to obtain epoxy resin / iron phenyl phosphate composite. Combustion performance results show that when the addition of the FePP nanosheets reaches 4% by weight, oxygen index increases to 35.1, reaching V-1 level (t1+t2 equals 15 s), heat release rate peak is 42.6% less than that of pure epoxy resin, and heat release total quantity decreases by about 26.3%; additionally, smoke release total quantity decreases by 32.8%, and CO release quantity decreases by 50.0%. The preparation method herein is simple and feasible, the epoxy resin / iron phenyl phosphate composite has excellent flame retardance and smoke-inhibiting efficiency and is applicable to flame-retardant protection for the matrix materials, such as foam, plastics, and rubber.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

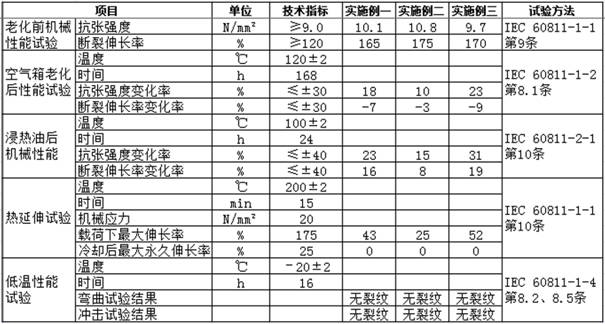

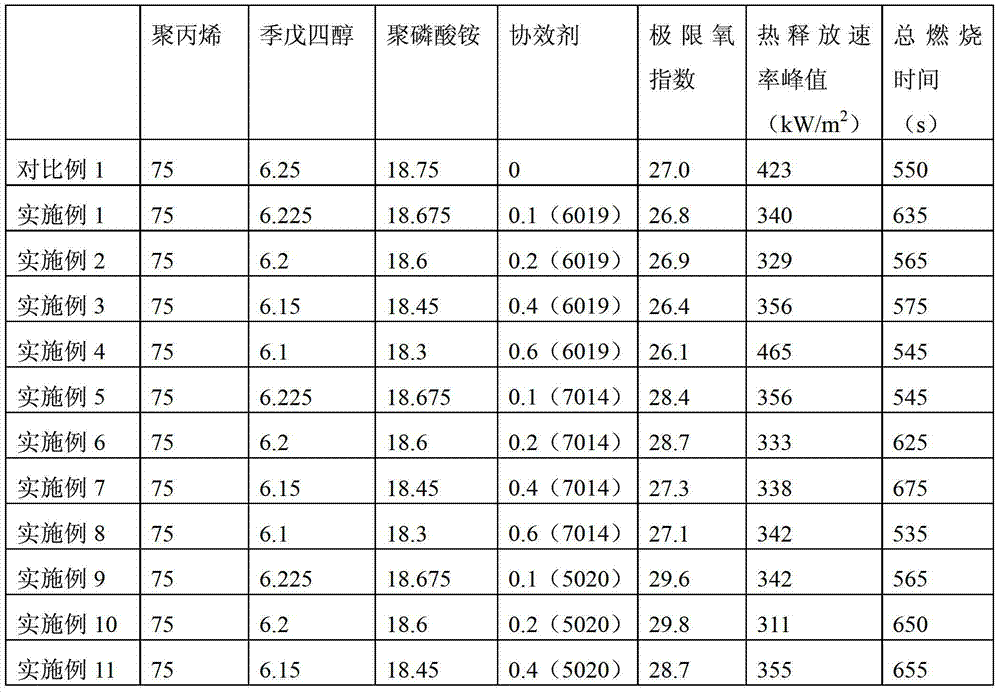

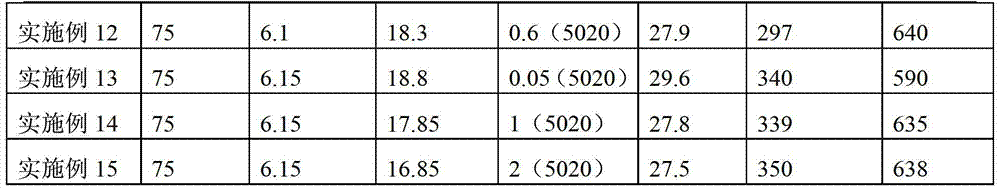

A kind of flame-retardant thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN104072977BReduce peak heat release rateIncreased vertical burn test levelCarbon layerElastomer composites

The invention relates to a flame-retardant thermoplastic polyurethane elastomer and a preparation method thereof. The invention adopts the expanded flame-retardant polypropylene and thermoplastic polyurethane elastomer composite material prepared by the composite expanded flame retardant, and its vertical burning test level is improved to V-0 level, and a dense expanded carbon layer is formed on the surface of the sample, which has a good performance Flame retardant effect. The use of hollow glass microspheres and intumescent flame retardants to synergistically flame-retardant polypropylene and thermoplastic polyurethane elastomers not only greatly improves the oxygen index of the composite material, but also significantly improves the vertical combustion performance reflecting the droplet resistance, which can be very good It reduces the heat release rate and has a significant smoke suppression effect. It can also significantly reduce the viscosity of the polymer melt and improve the processing performance.

Owner:ZIBO HENGJIU PU TECH

Composite Intumescent Flame Retardant and Its Application in Flame Retardant Polypropylene and Polyurethane

InactiveCN103333364BReduce peak heat release rateIncreased vertical burn test levelCarbon layerThermoplastic

The invention relates to a compound intumescent flame retardant (IFR) and an application thereof to carrying out flame retardance on polypropylene (PP) and polyurethane (PU) elastomers. The compound IFR comprises hollow glass microspheres and IFRs. The vertical flame test level of the IFR PP and thermoplastic PU (TPU) elastomer composite material prepared by adopting the compound IFR is raised to V-0, and a dense intumescent carbon layer is formed on the surface of a sample of the IFR PP and TPU elastomer composite material, so that the IFR PP and TPU elastomer composite material has a good flame retardant effect. By using the hollow glass microspheres and the IFRs to carry out synergistic flame retardance on the PP and TPU elastomers, not only is the oxygen index of the composite material increased and the vertical flammability reflecting melting and dropping resistance obviously improved, can the heat release rate be well reduced and are obvious smoke suppression effects achieved, but also the viscosity of the polymer melts can be obviously reduced and the processability can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

A Silicon/Phosphorus Synergistic Flame Retardant Polyamide Resin

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Clean flame-retardant and smoke-suppressive epoxy resin nanocomposite material and preparation method thereof

The invention discloses a clean flame-retardant and smoke-suppressing epoxy resin nanocomposite material and a preparation method thereof. The clean flame-retardant and smoke-suppressing epoxy resin nanocomposite material is composed of K 2 co 3 (P 2 o 7 ) 2 2H 2 O Nanomaterial flame retardant, epoxy monomer, 4,4'-diaminodiphenylmethane composite preparation, wherein K 2 co 3 (P 2 o 7 ) 2 2H 2 The mass percentage of O nanometer material is 1~12wt%, and the rest is the mixture of epoxy monomer and 4,4'-diaminodiphenylmethane, and the mass percentage of epoxy monomer and 4,4'-diaminodiphenylmethane The ratio is 4:1. The present invention aims at the existing flame retardant epoxy resin composite materials containing toxic elements such as halogen and poor smoke suppression and mechanical properties. The present invention proposes a halogen-free K2Co3(P2O7)2. It has the characteristics of clean and pollution-free, good flame retardant and smoke suppression performance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ZHENJIANG POWER SUPPLY CO

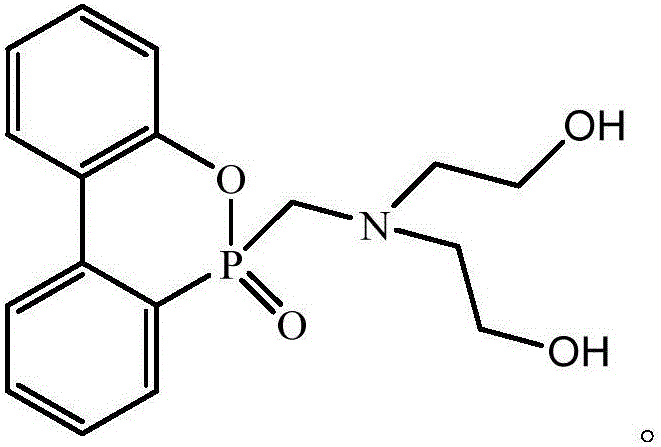

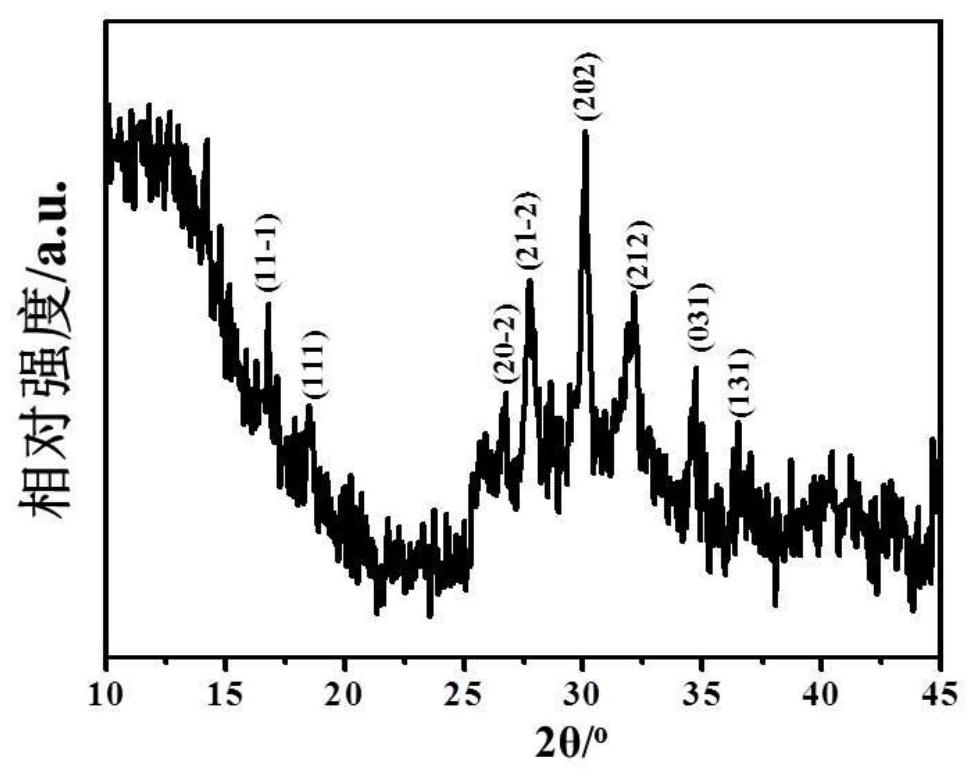

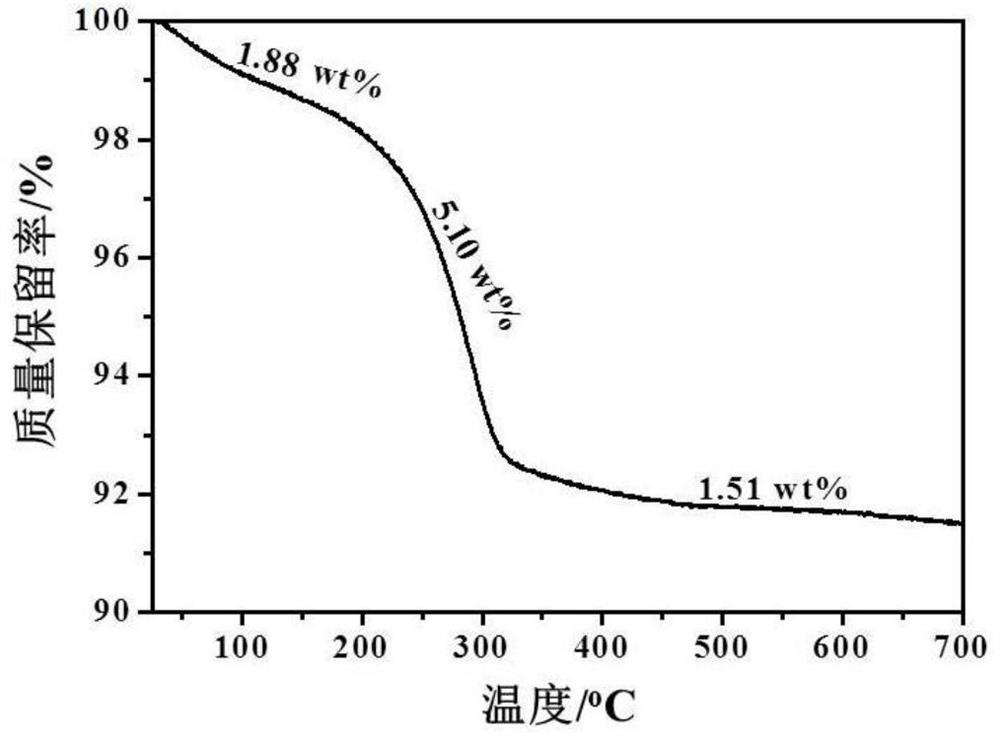

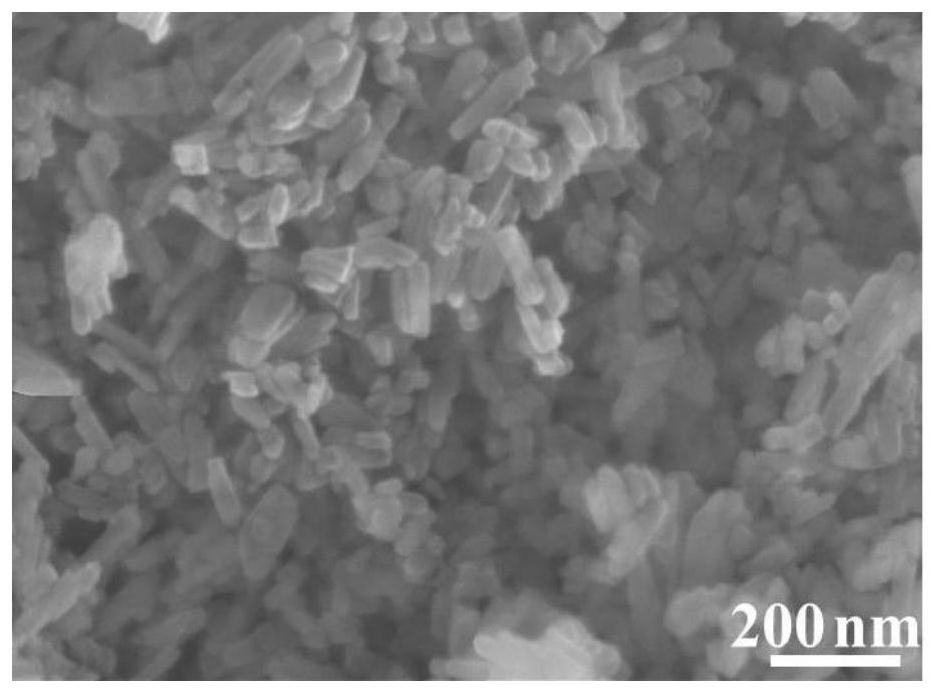

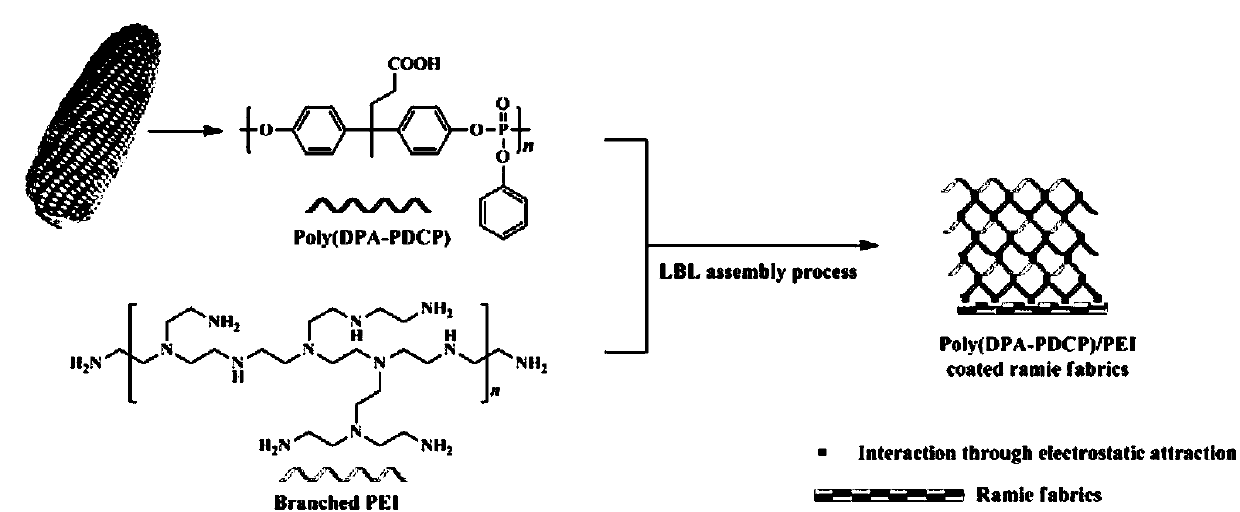

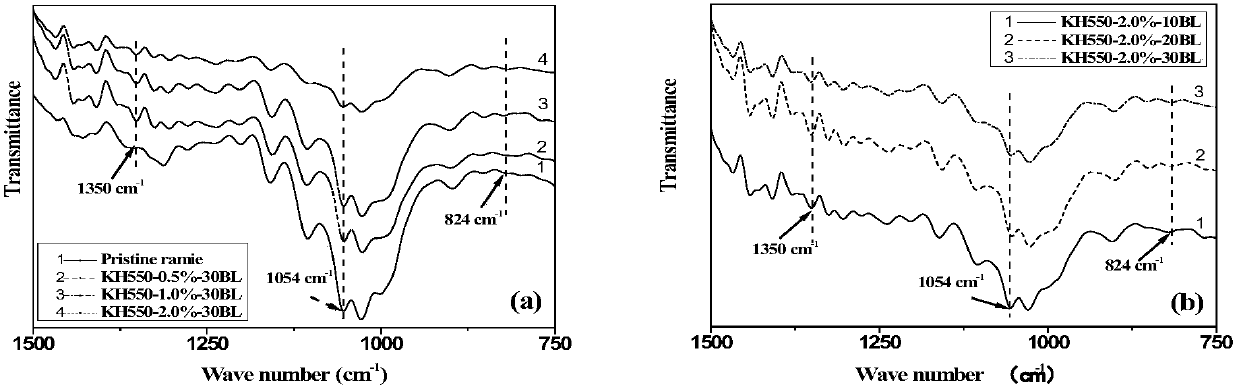

A kind of preparation method of flame retardant modified ramie fabric

ActiveCN105507000BCheap chemical structureEasy to chemically modifyHeat resistant fibresVegetal fibresPhenyl phosphateDiphenolic acid

The invention provides a preparation method of a flame-retardant modified ramie fabric. The method comprises the following steps of soaking a ramie fabric in a coupling agent solution for 1-2 hours, and taking out and drying the soaked ramie fabric; soaking the dried ramie fabric in a poly-diphenolic acid phenyl phosphate ester solution for 5-10 minutes, and washing the soaked ramie fabric 1-3 times with deionized water; drying the washed ramie fabric, soaking the dried ramie fabric in a polyethyleneimine solution for 5-10 minutes, and then washing the soaked ramie fabric for 5-10 minutes; cleaning the soaked 1-3 times with the deionized water, and drying the cleaned ramie fabric; and repeating the process until the required layer number is achieved, and then performing drying, so as to obtain the objective namely the flame-retardant modified ramie fabric. The preparation method is simple in technological operation, flexible, and good in stability, and the flame retardancy of the ramie fabric can be effectively improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Strengthened and toughened modified urea-formaldehyde resin foam insulation material and preparation method thereof

The invention discloses a strength / toughness-modified urea formaldehyde resin foam thermal-insulation material and a preparation method thereof. The urea formaldehyde resin foam material is prepared from the following raw materials in percentage by weight: 80-97% of urea formaldehyde resin, 0.1-3% parts of foaming agent, 0.5-4% of surfactant, 0.1-1% of thickener, 0.1-1.5% of curing agent and 0.1-10% of modifier. The urea formaldehyde resin is synthesized by a three-step method; and the modifier can be added in the urea formaldehyde resin synthesis and foam emulsion preparation process. By adopting the physical foaming method, the uniform and stable foam emulsion is firstly prepared, and then, the foam emulsion is freely expanded in an open container. The strength / toughness-modified urea formaldehyde resin foam thermal-insulation material has the advantages of simple technique, low cost, favorable flame retardancy, small heat conductivity coefficient and small fire hazard coefficient, and can be applied to the field of building thermal-insulation materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

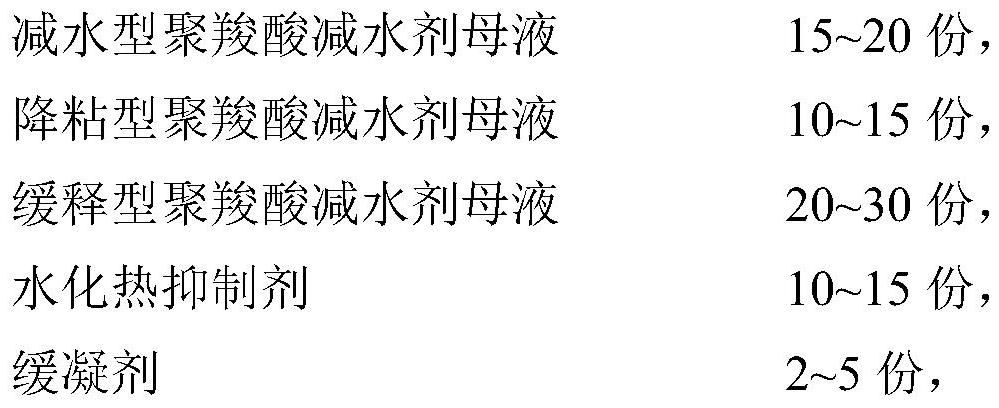

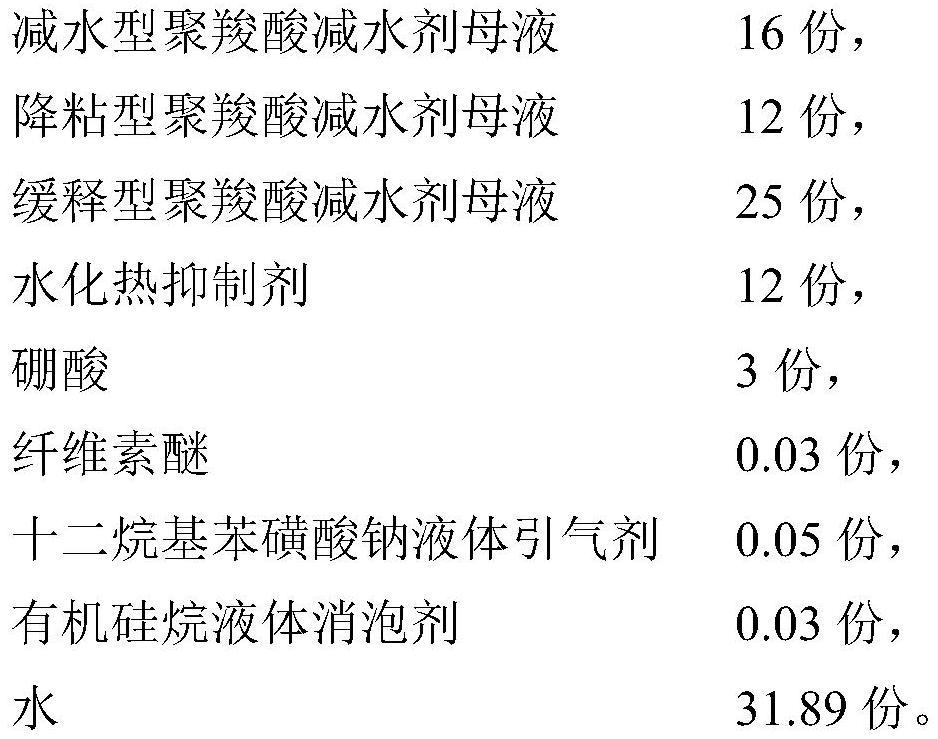

A composite high-performance polycarboxylate water reducer and its preparation method and application

ActiveCN110372255BReduces hydration concentrationReduce peak heat release rateAcid waterEnvironmental engineering

The invention provides a composite high-performance polycarboxylate water reducer and its preparation method and application, and relates to the technical field of concrete. The composite high-performance polycarboxylate superplasticizer is prepared from the following raw materials in parts by weight: 15-20 parts of the mother liquor of the water-reducing polycarboxylate superplasticizer, and 10-15 parts of the mother liquor of the viscosity-reducing polycarboxylate superplasticizer , 20-30 parts of slow-release polycarboxylate superplasticizer mother liquor, 10-15 parts of heat of hydration inhibitor, 2-5 parts of retarder, 0-0.1 part of consistency regulator, 0-0.06 part of air-entraining agent, 0-0.05 part of defoamer. The composite high-performance polycarboxylate water reducer of the present invention is applied to barite concrete, which can effectively improve the fluidity, pumpability and stability of barite concrete, slow down the heat release rate of hydration, and prevent wall cracking.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com