A kind of preparation method of silicate flame retardant dense wood

A silicate and wood technology, applied in wood heating, wood impregnation, wood treatment and other directions, can solve the problems of high cost and high brittleness of impregnated modified materials, achieve low cost, improve flame retardancy, and be suitable for popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

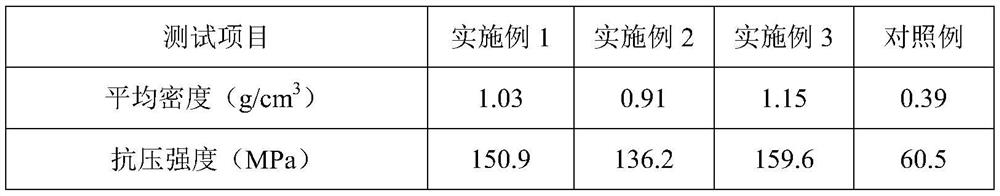

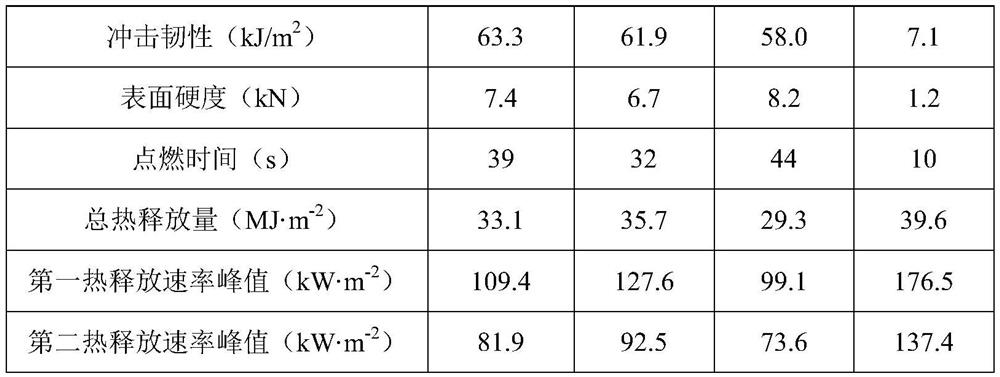

Examples

Embodiment 1

[0023] A method for preparing silicate flame-retardant dense wood, wherein the raw wood for preparing flame-retardant dense wood is selected from artificial forest wood. This embodiment takes poplar as an example to describe in detail:

[0024] (1) Dry the wood for 24 hours under the condition of (103±5° C.), and set it aside; then prepare a sodium chlorite solution with a mass fraction of 2.5% in distilled water, and add an appropriate amount of glacial acetic acid (98%) to adjust the pH value of the solution to 4.6; Put the dried wood into the acidic sodium chlorite solution, raise the temperature to 100°C, keep the liquid level higher than the wood sample and boil for 24 hours, and finally rinse the wood with distilled water several times.

[0025] (2) Select sodium silicate with a modulus of 3.3, configure a sodium silicate solution with a mass fraction of 35%, and slowly add 3-aminopropyltriethoxy with a mass fraction of 3% of the entire sodium silicate solution. Silane (...

Embodiment 2

[0030] A method for preparing silicate flame-retardant dense wood, wherein the raw wood for preparing flame-retardant dense wood is selected from artificial forest wood. This embodiment takes poplar as an example to describe in detail:

[0031] (1) Dry the wood for 24 hours under the condition of (103±5° C.), and set it aside; then prepare a sodium chlorite solution with a mass fraction of 2.5% in distilled water, and add an appropriate amount of glacial acetic acid (98%) to adjust the pH value of the solution to 4.6; Put the dried wood into the acidic sodium chlorite solution, raise the temperature to 100°C, keep the liquid level always higher than the wood sample and boil for 12 hours, and finally rinse the wood with distilled water several times.

[0032] (2) Select sodium silicate with a modulus of 3.3, configure a sodium silicate solution with a mass fraction of 30%, and slowly add 3-aminopropyltriethoxy with a mass fraction of 1% of the entire sodium silicate solution. S...

Embodiment 3

[0037] A method for preparing silicate flame-retardant dense wood, wherein the raw wood for preparing flame-retardant dense wood is selected from artificial forest wood. This embodiment takes poplar as an example to describe in detail:

[0038] (1) Dry the wood for 24 hours under the condition of (103±5° C.), and set it aside; then prepare a sodium chlorite solution with a mass fraction of 2.5% in distilled water, and add an appropriate amount of glacial acetic acid (98%) to adjust the pH value of the solution to 4.6; Put the dried wood into the acidic sodium chlorite solution, raise the temperature to 100°C, keep the liquid level higher than the wood sample and boil for 24 hours, and finally rinse the wood with distilled water several times.

[0039](2) Select sodium silicate with a modulus of 3.3, configure a sodium silicate solution with a mass fraction of 40%, and slowly add 3-aminopropyltriethoxy with a mass fraction of 3% of the entire sodium silicate solution. Silane (K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com