Patents

Literature

80results about How to "Prolong ignition time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

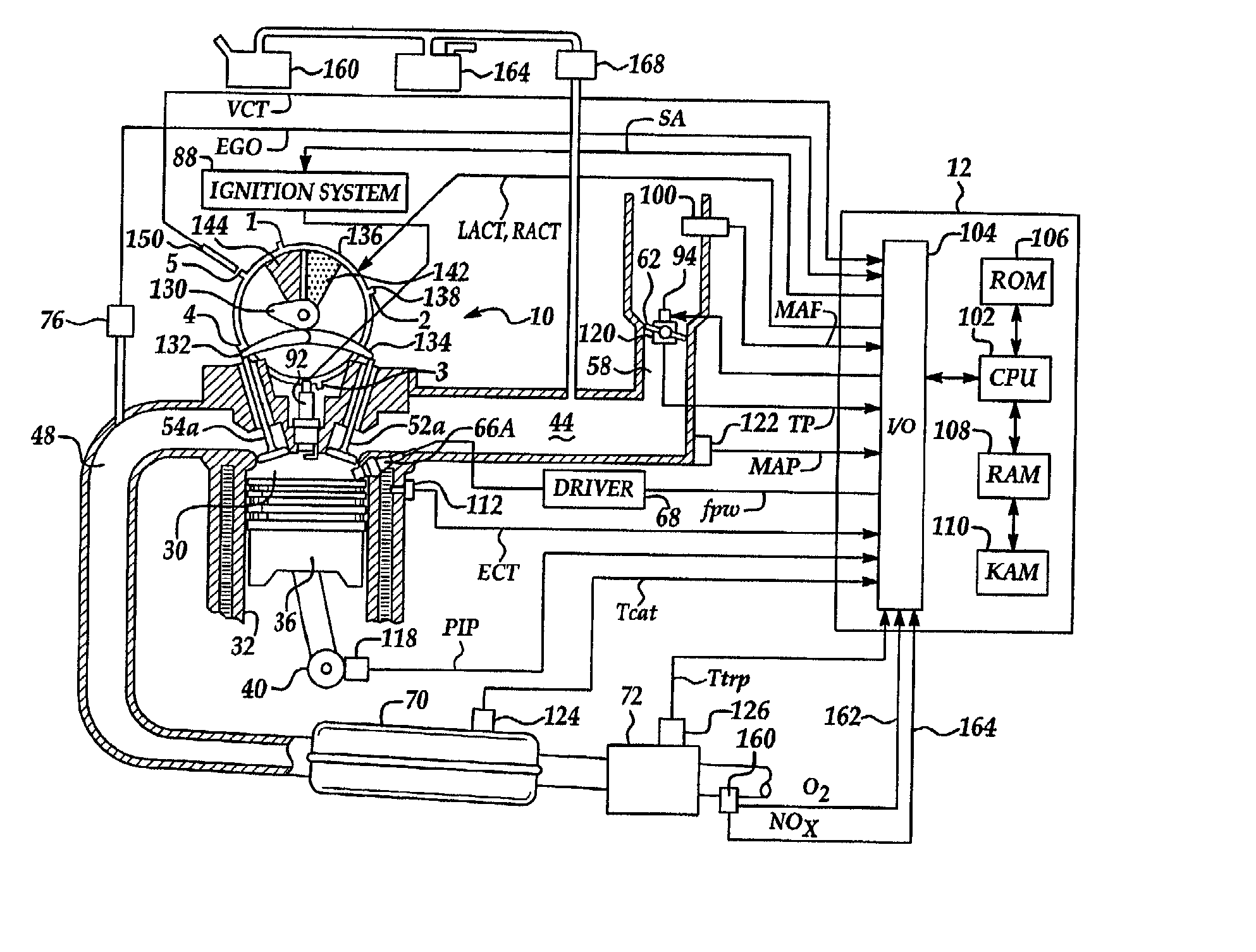

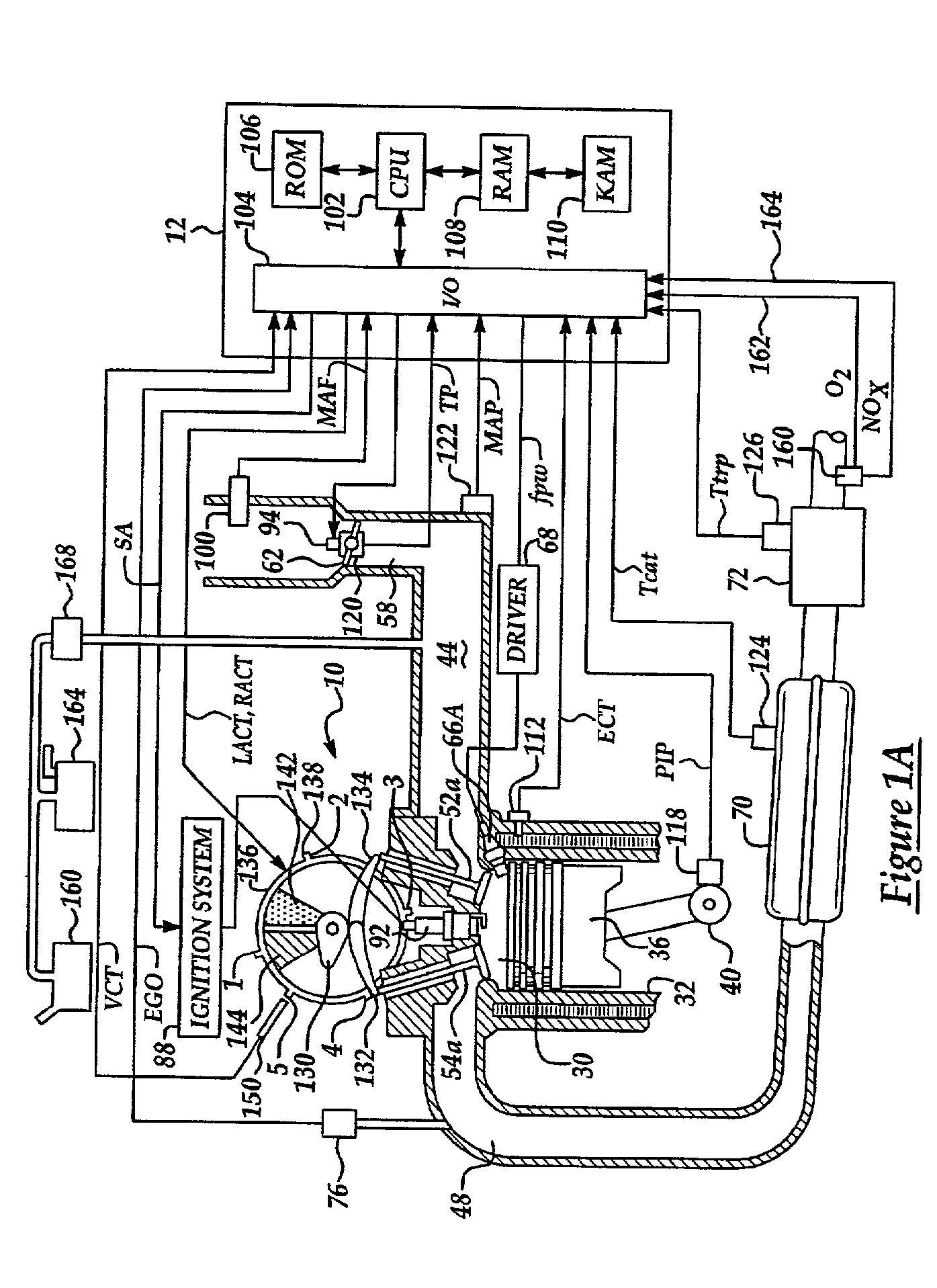

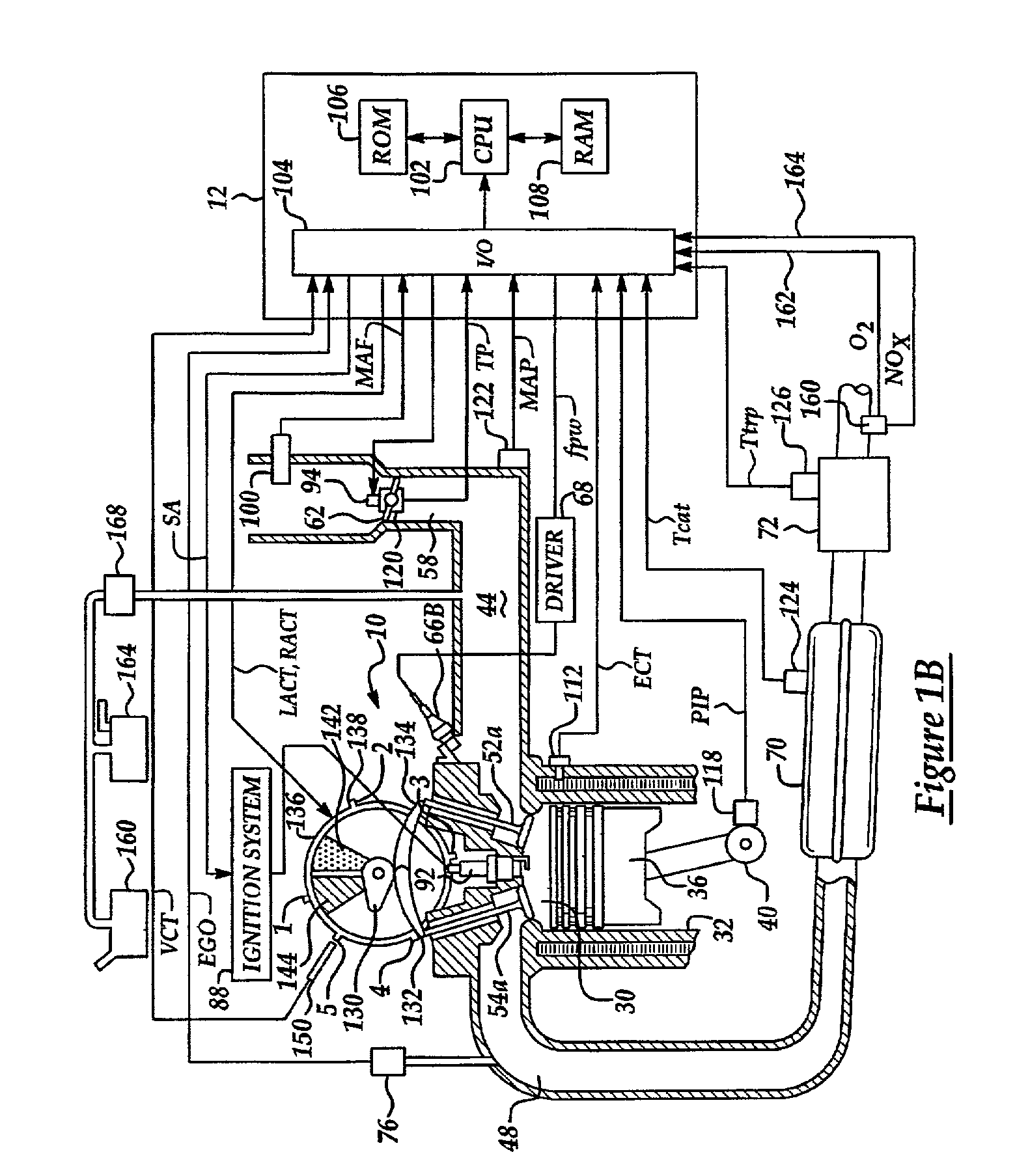

Method for split ignition timing for idle speed control of an engine

InactiveUS20030221664A1High load conditionMore ignition timingAnalogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Fire-retardant polyolefin based wood plastic composite material and preparation method thereof

ActiveCN102321374AGood smoke suppression performanceExcellent flame retardancy and mechanical propertiesPolyolefinEnvironmentally friendly

The invention discloses a fire-retardant polyolefin based wood plastic composite material and a preparation method thereof, and relates to a wood plastic composite material and a preparation method thereof, and the composite material and method provided by the invention can be used for solving problems that the existing fire-retardant wood plastic composite material has high heat release efficiency in burning and high smoke production, and can generate CO harmful gas easily. The flame-retardant polyolefin based wood plastic composite material is prepared from wood fiber materials, plastics, acoupling agent, a lubricant, an antioxidant, a nano inorganic fire retardant and a mineral filler. The method comprises the following steps: putting the wood fiber materials, the coupling agent and the lubricant into a high-speed mixing machine for hot mixing; then putting into a cold mixing machine for cold mixing, sending the plastics, the antioxidant, the nano inorganic fire retardant and the mineral filler into the cold mixing machine and then mixing; and then carrying out fusing and extruding for granulation by adopting extruding, injection, hot compressing or mold compression for molding, thus the fire-retardant polyolefin based wood plastic composite material is obtained. The wood plastic composite material provided by the invention has low heat release rate in burning and less smoke production, and is healthy and environmentally-friendly, and can be widely applied to the fields of indoor construction, decoration and furnishing materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

High-flame-retardancy paint

InactiveCN106366740AHigh tensile strengthImprove adsorption capacityFireproof paintsPolyurea/polyurethane coatingsWater basedDimethyl methylphosphonate

The invention discloses a high-flame-retardancy paint which is prepared from a water-based acrylate emulsion, a water-based polyurethane resin, aluminasol, an epoxy resin, polydimethylsiloxane, zinc oxide, hollow glass microspheres, nano zirconium oxide, montmorillonite, nano silicon dioxide, a film forming aid, a defoaming agent, a leveling agent, a wetting agent, a flame retardant and water. The flame retardant is formed by mixing boron oxide, dimethyl methyl phosphonate, phosphorus pentoxide, tri(2-chloropropyl) phosphate, guanylurea phosphate, ammonium polyphosphate, pentaerythritol, melamine and hexamethyl disiloxane. The high-flame-retardancy paint has the advantages of favorable water resistance, favorable wear resistance, excellent flame retardancy and long service life.

Owner:ANHUI JINDUN PAINT

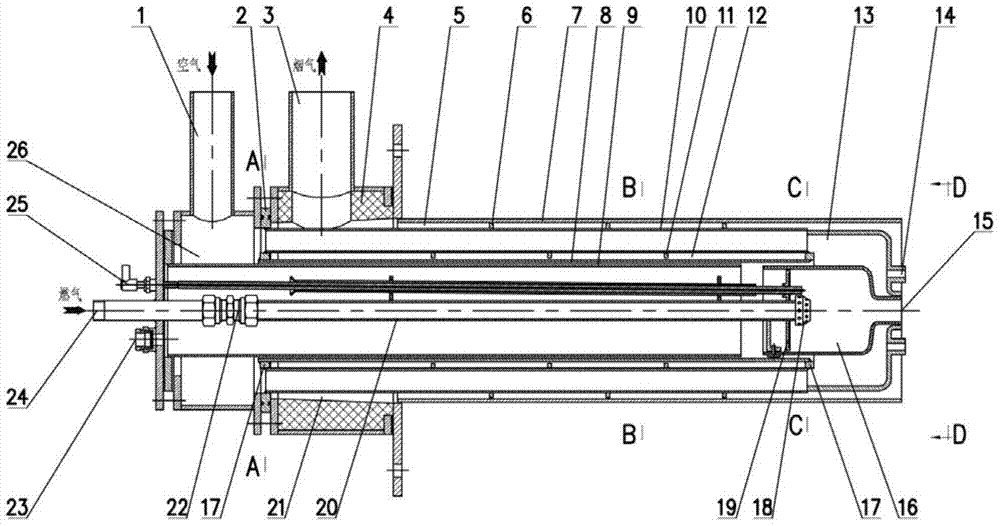

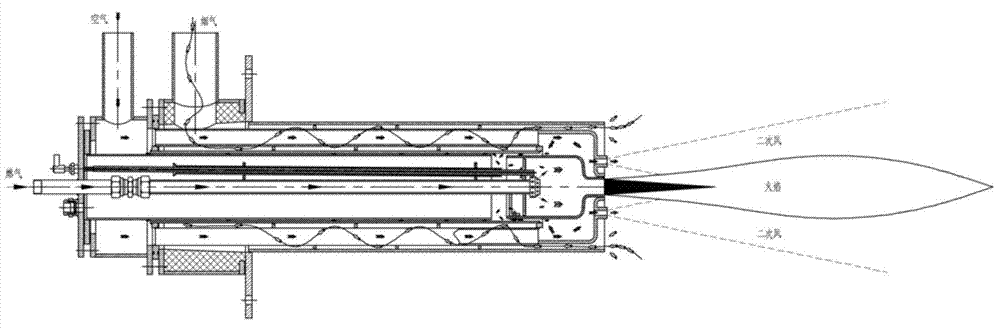

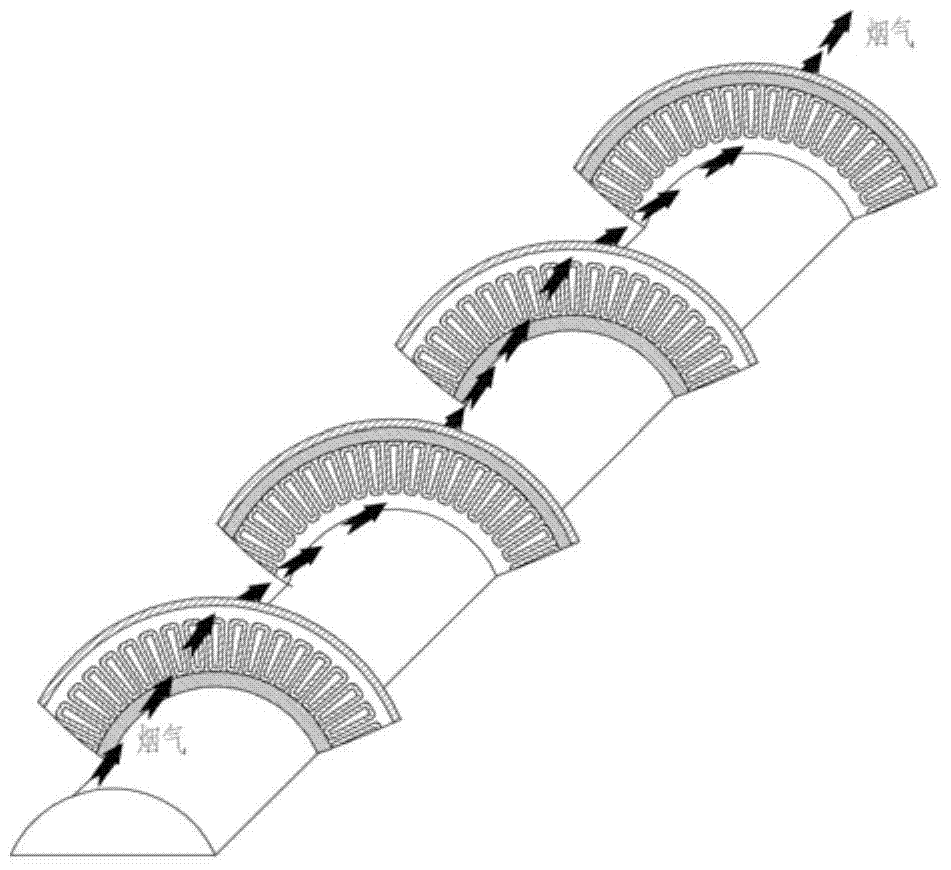

Efficient counter-distributary self-preheating low-NOx combustion device

InactiveCN103939903AIncrease the heat exchange areaReduce concentrationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEngineering

The invention discloses an efficient counter-distributary self-preheating low-NOx combustion device. The combustion device comprises a gas core tube and a combustion chamber arranged at the front end of the gas core tube. A gas sprayer head of the gas core tube is located in the combustion chamber, and an air outlet air chamber is further arranged outside the combustion chamber in a sleeved mode. The gas core tube is sleeved with an air inner sleeve used for delivering combustion air into the combustion chamber, the air inner sleeve is sleeved with an annular smoke channel, and a plurality of special tubes used for increasing the heat exchange area are arranged in the smoke channel at equal intervals in the axial direction. A plurality of secondary air holes are formed in the air outlet air chamber, secondary air and a mixture after combustion are both sprayed into a hearth at high speed, a large amount of smoke can be induced to flow back, the concentration of fuel and O2 is reduced, the temperature of flames is lowered, and formation of heating power NOx is reduced. Meanwhile, air is distributed to the secondary air holes through the air outlet air chamber and sprayed into the hearth at high speed, and thus the ignition time can be effectively prolonged. The running cost of the combustion device and NOx emission can be reduced, and the combustion device can contribute to energy conservation and environment protection.

Owner:XI AN JIAOTONG UNIV

Flame-retardant wallpaper and preparation method thereof

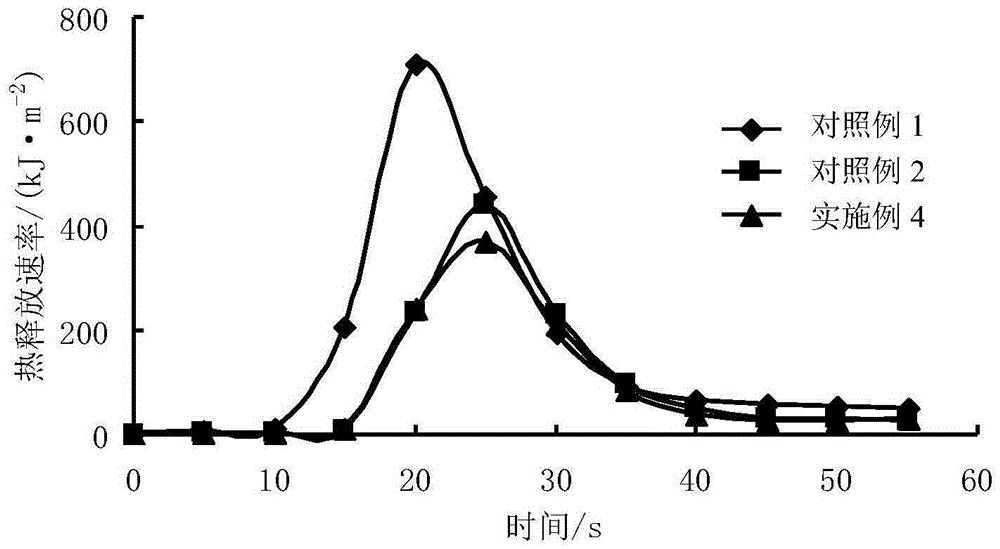

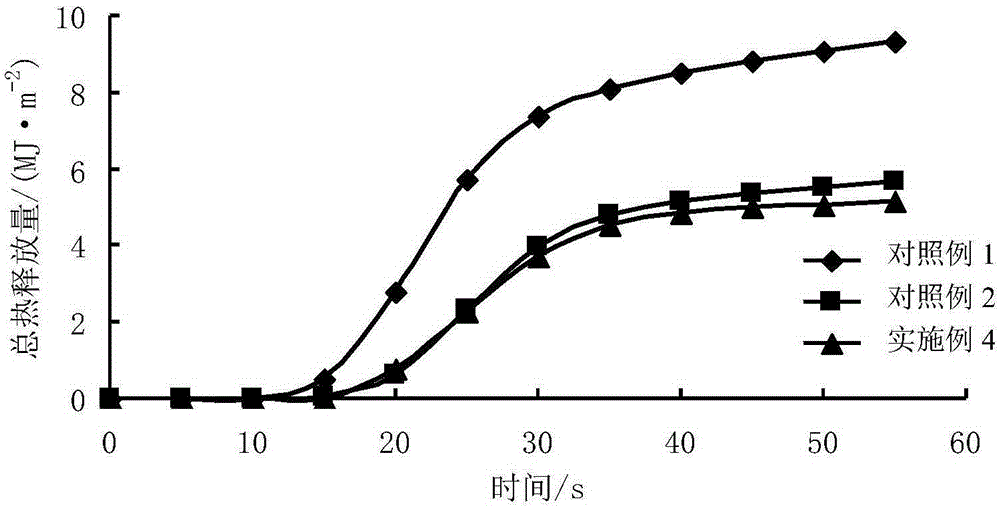

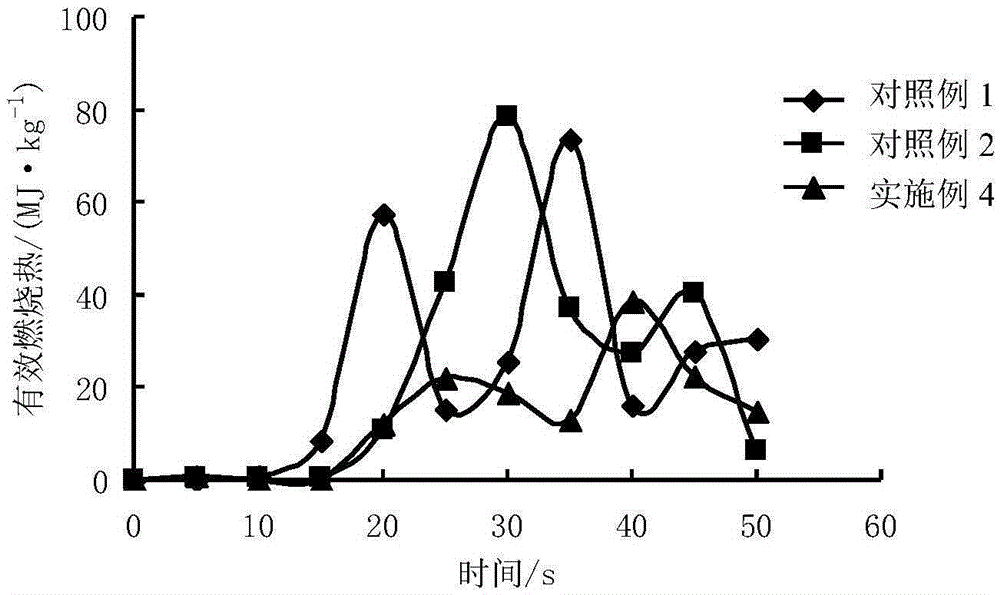

ActiveCN105297551AImprove flame retardant performanceTotal calories lowSpecial paperLaminationToxic gasFire risk

The invention discloses flame-retardant wallpaper as an indoor wall decoration material and a preparation method thereof. The preparation method for the flame-retardant wallpaper includes the following steps: after being immersed in a flame retardant solvent, a decorative veneer and a wallpaper substrate (backing paper) are ultrasonically immersed, so that a flame-retardant decorative veneer and a flame-retardant substrate are obtained; the flame-retardant decorative veneer is attached onto the surface of the flame-retardant substrate. The flame-retardant property of the wallpaper is good, the potential fire risk is low when the material burns, and the flame-retarding effect is remarkable; the smoke suppression effect is obvious, the amount of CO released from smoke is obviously reduced, toxic CO gas can be partially turned into non-toxic gas, and the wallpaper has a good effect of suppressing CO released at fire scenes. Moreover, since the adopted materials are natural materials, the wallpaper is safe to use.

Owner:沈阳领拓科技有限公司

Firework with integral module explosive filling structure in open mode and preparation method thereof

The invention discloses a firework with an integral module explosive filing structure in an open mode and a preparation method thereof. The explosive filling structure disclosed by the invention comprises a shell, a delay fuse, bright beads and an open explosive module, wherein the shell, the delay fuse and the bright beads are made of traditional materials. The preparation method of the fireworkwith the integral module explosive filling structure in an open mode comprises the following steps: preparing a slurry containing an organic adhesive, an ignition performance reinforcing agent and granular micro-pore firework explosive granules; then, filling the bright beads and the slurry into the ball shell of the firework according to the needed structure, thus forming an integral module structure; and finishing the preparation of the firework according to a conventional method. By adopting the integral module explosive filling structure and the explosive filling method, the gap between the open explosive module and the bright beads is basically eliminated; the ignition rate of the bright beads can be improved; the mechanical friction action among the granules in the explosive fillingcourse and storage and transportation course of the granules is avoided; and the safety of the preparation course and storage and transportation course of fireworks is improved.

Owner:NANJING UNIV OF SCI & TECH

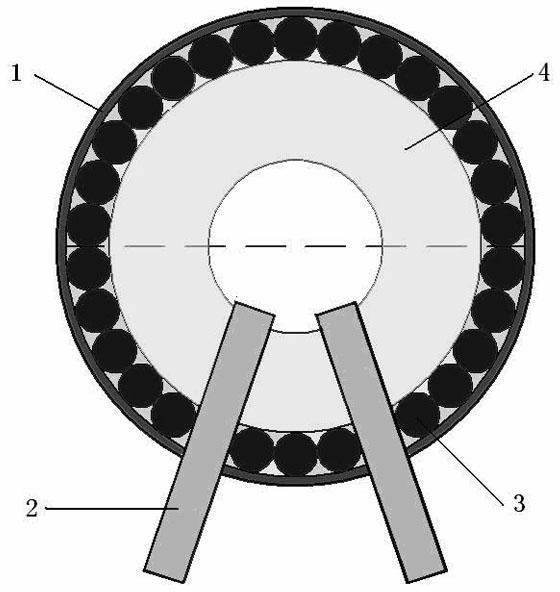

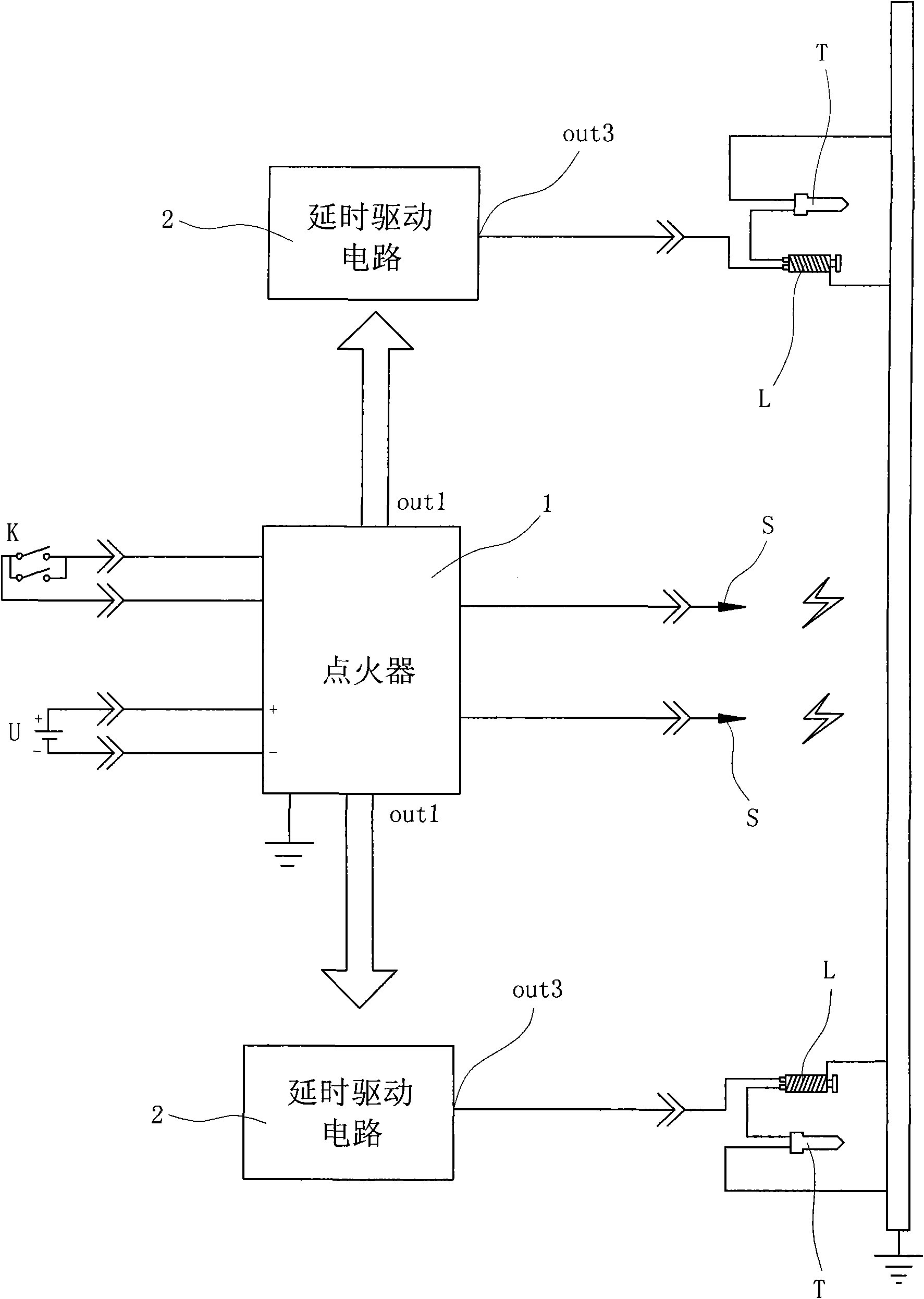

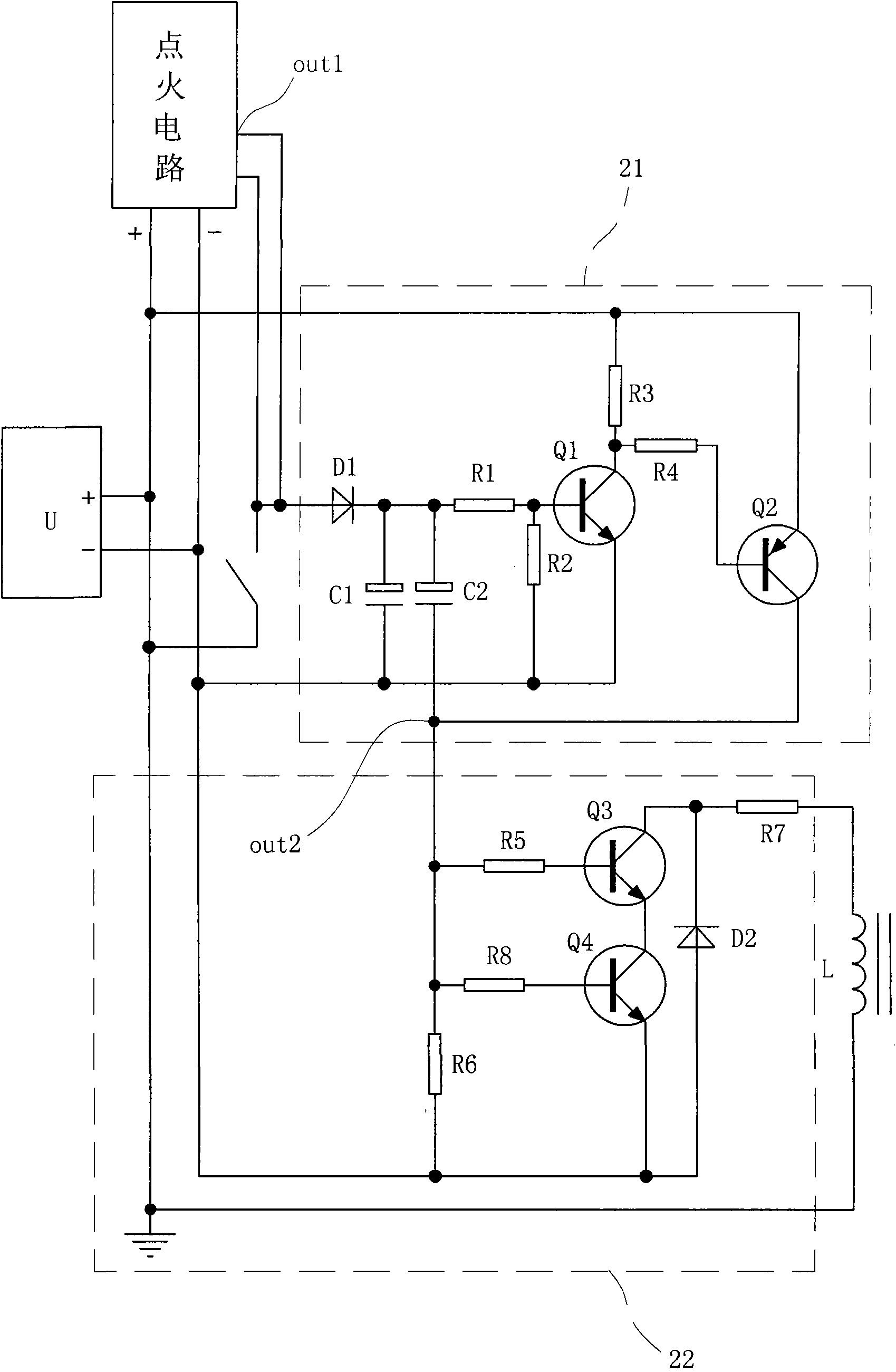

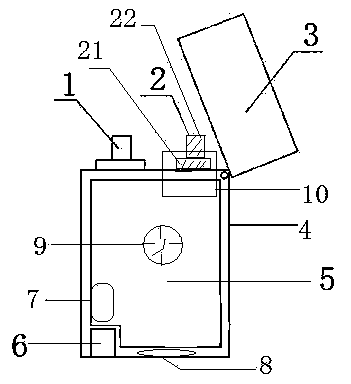

Gas stove ignition device

ActiveCN101598354AGuaranteed electromotive forceImprove securityDomestic stoves or rangesOperating means/releasing devices for valvesDriver circuitEngineering

The invention relates to a gas stove ignition device, comprising an igniter, a gas source electromagnetic valve coil and a thermocouple; the ignition device is characterized in that: the ignition device also comprises a delay driving circuit, the positive input end of the delay driving circuit power is connected with the positive of a power supply, the negative input end of the delay driving circuit power is connected with the negative of the power supply; the trigger end of the delay driving circuit is connected with the output end of the igniter, in addition, the output end of the delay driving circuit is connected with the gas source electromagnetic valve coil which is connected with the thermocouple in serial, the delay driving circuit can always keep the circuit conducting before the thermocouple is up to the electromotive force capable of sucking the gas source electromagnetic valve. Compared with the prior art, the ignition device sets up the delay driving circuit in the gas appliance ignition device, and the delay driving circuit can maintain the open time of the electromagnetic valve, thus users can successfully ignite without the need of pressing and turning on an ignition knob and then waiting a while, and the use is more convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

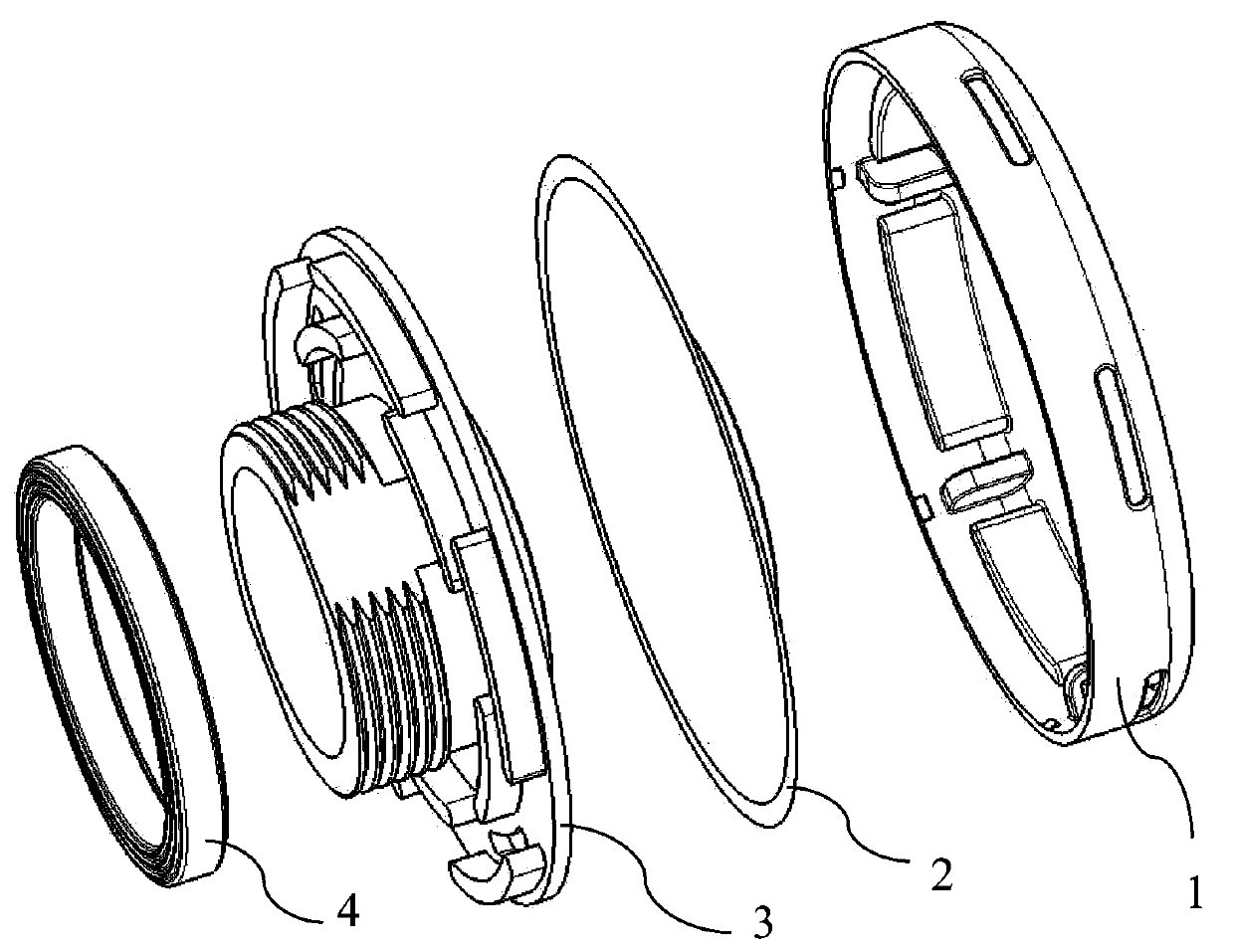

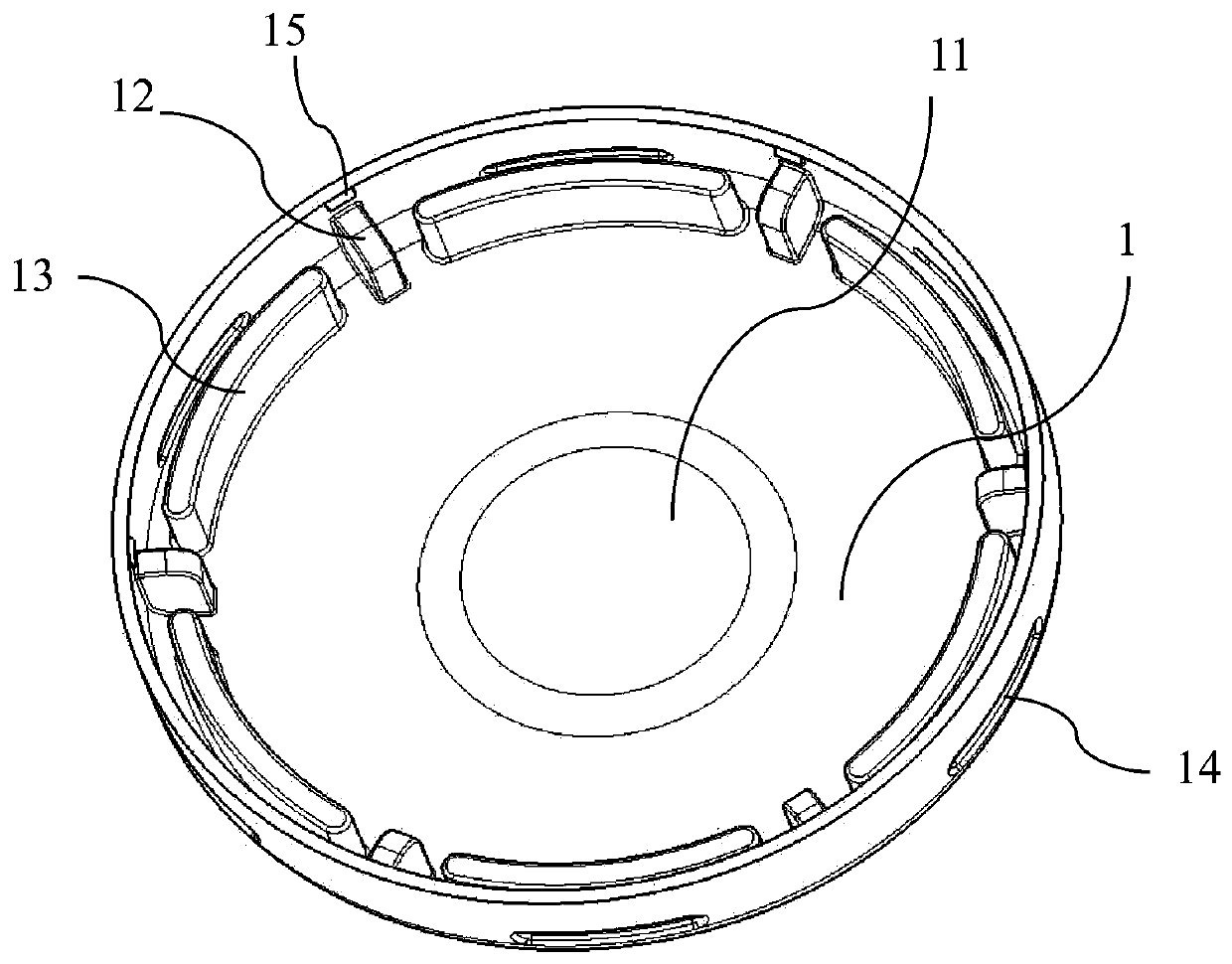

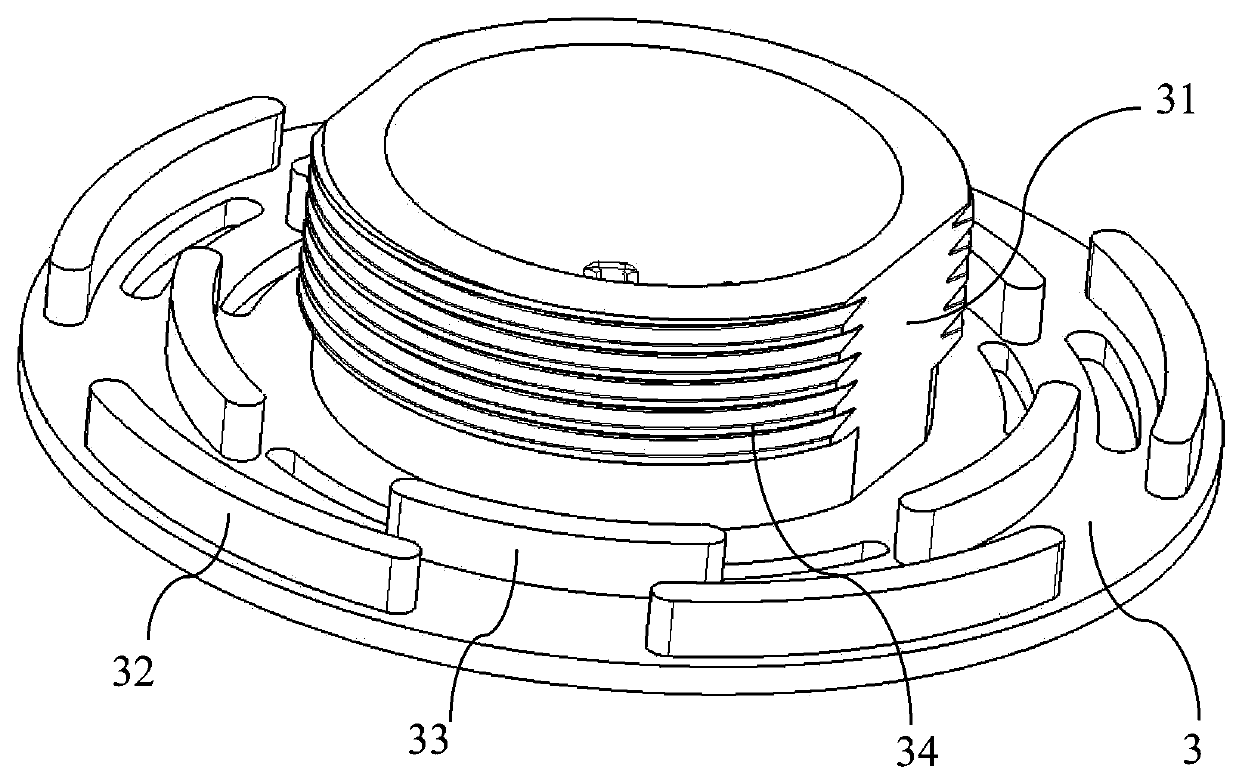

Breathable pressure release valve applied to power battery pack

The invention relates to the field of new energy automobiles, in particular to a breathable pressure release valve applied to a power battery pack. The breathable pressure release valve comprises a breathable valve protective cover, a breathable film and a breathable valve base; the breathable film is arranged between the breathable valve protective cover and the breathable valve base in a sleeving mode; a cavity structure with an opening is formed in the lower portion of a breathable valve protective cover main body; the inner edge of the cavity of the breathable valve protective cover is provided with a clamping structure used for clamping the breathable valve base; the outer edge of the breathable valve base is attached to the inner wall of the breathable valve protective cover; and a plurality of through vent holes are formed in the side walls of the breathable valve protective cover between the breathable valve protective cover and the breathable valve base in a point spacing mode. The breathable pressure release valve is convenient and rapid to mount; the breathable pressure release valve is mounted in a battery box shell with an opening position; the mounting can be completed by mounting a fastening piece in a box body; and the mounting process is short in time.

Owner:JIANGLING MOTORS

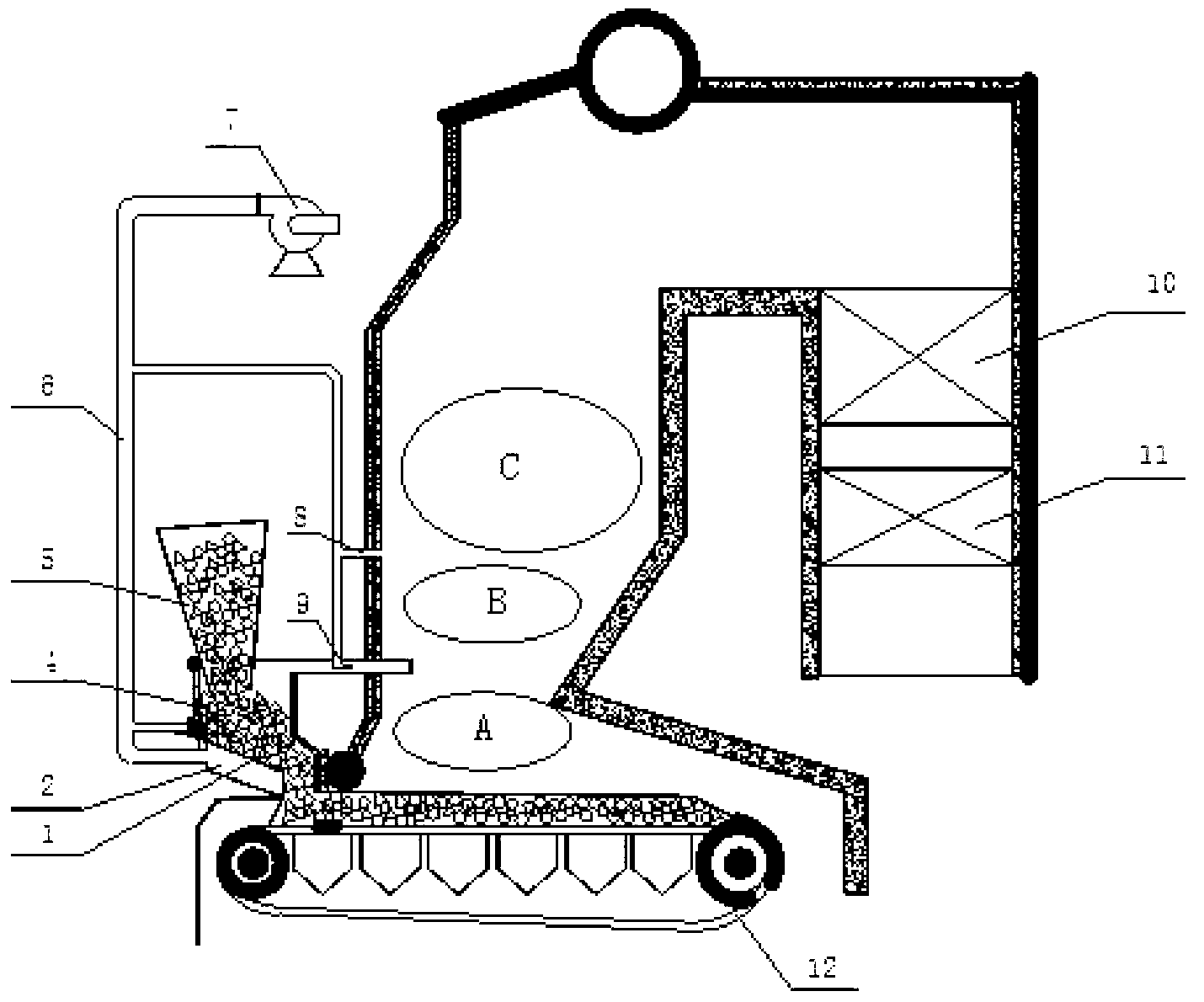

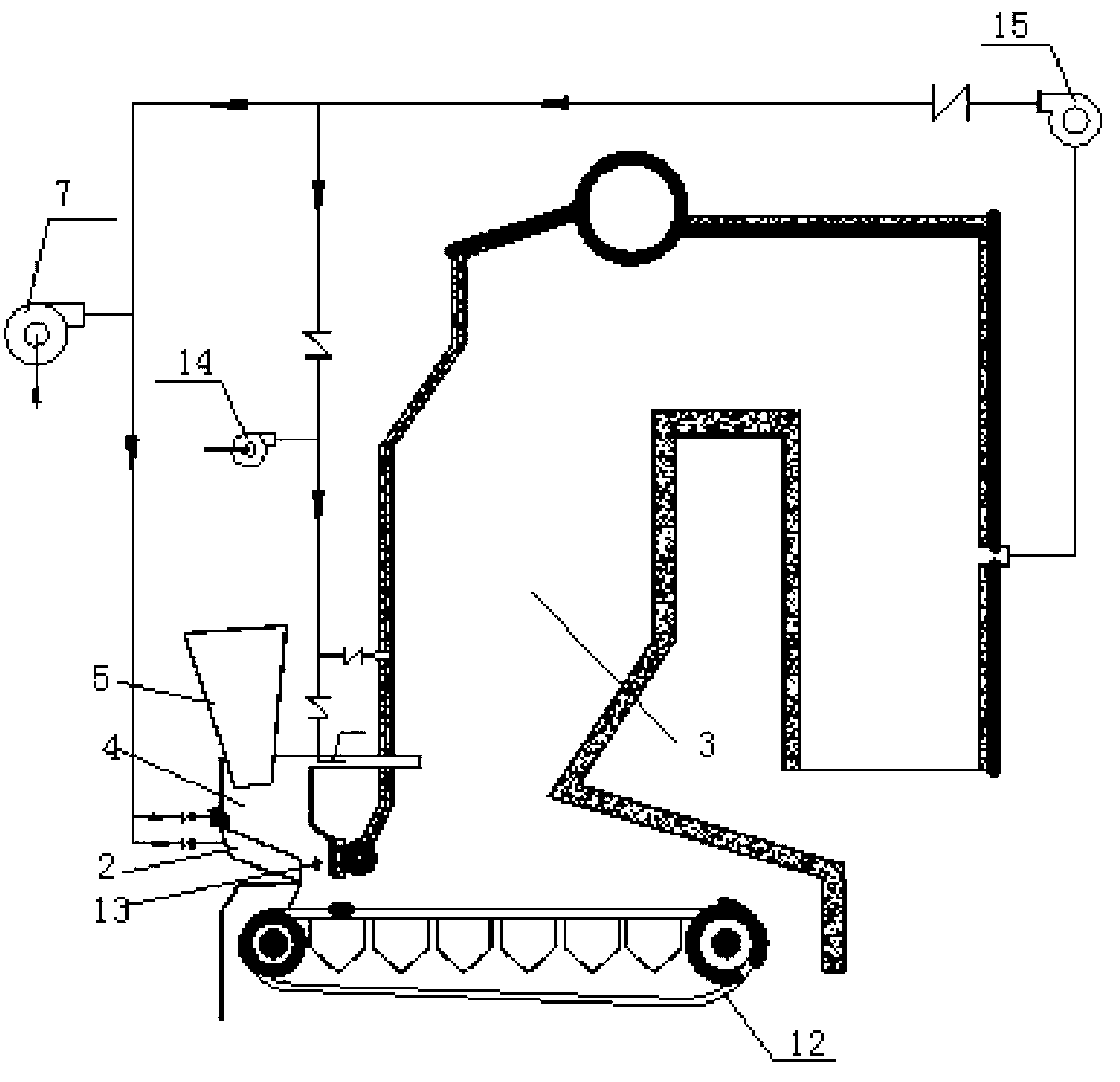

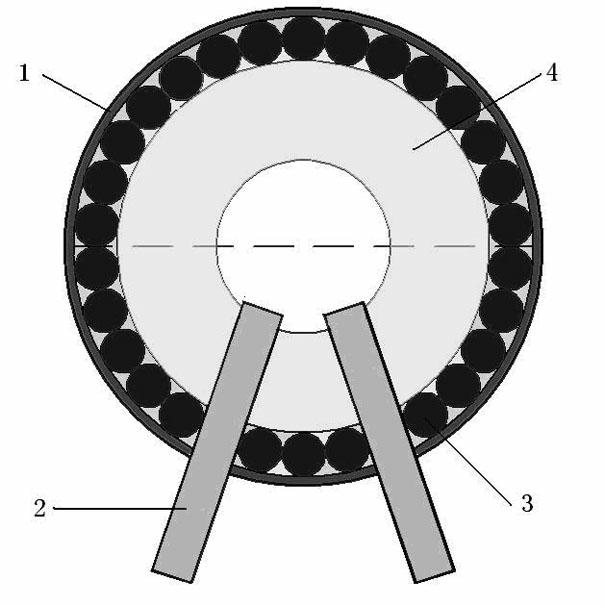

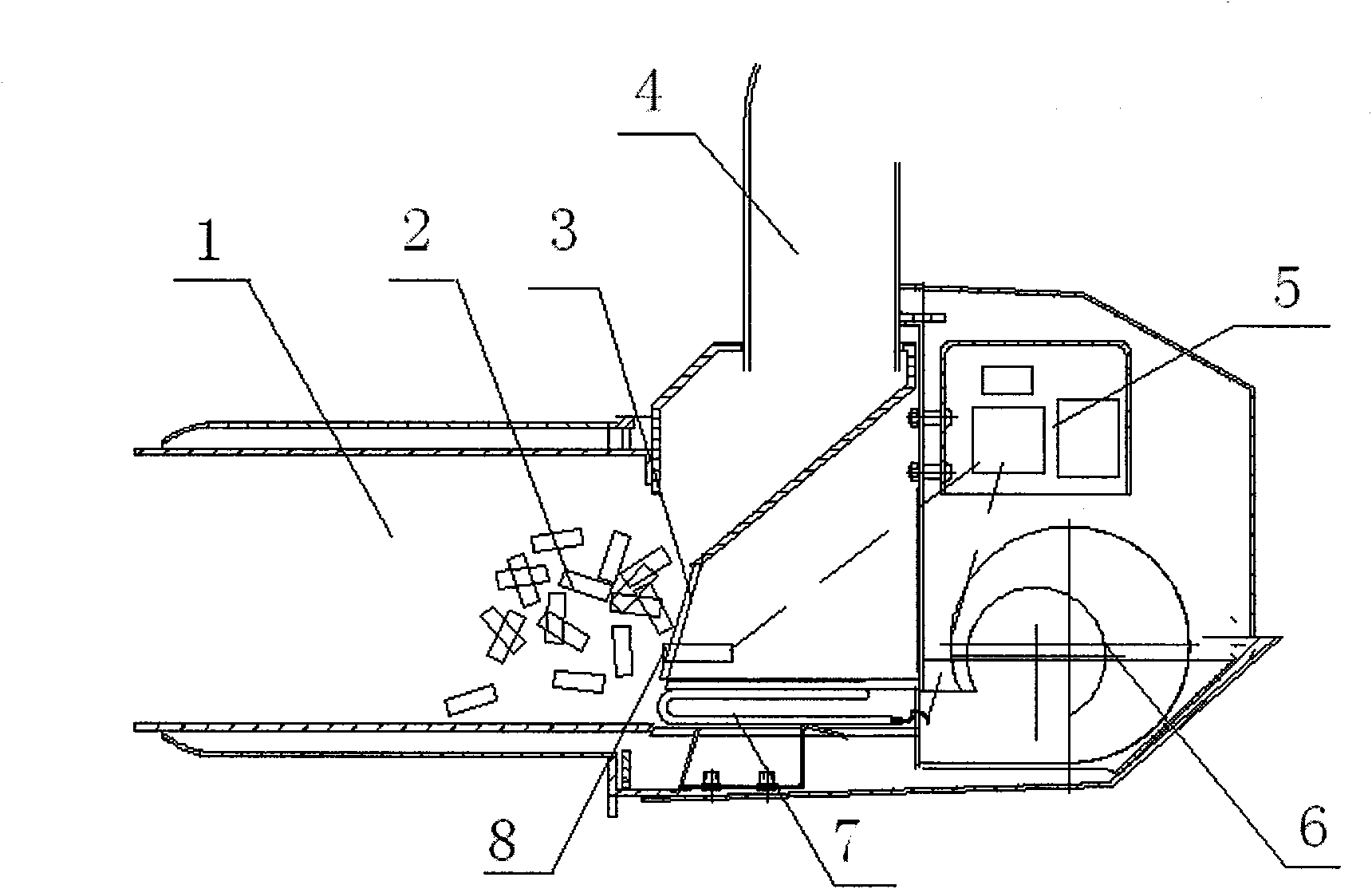

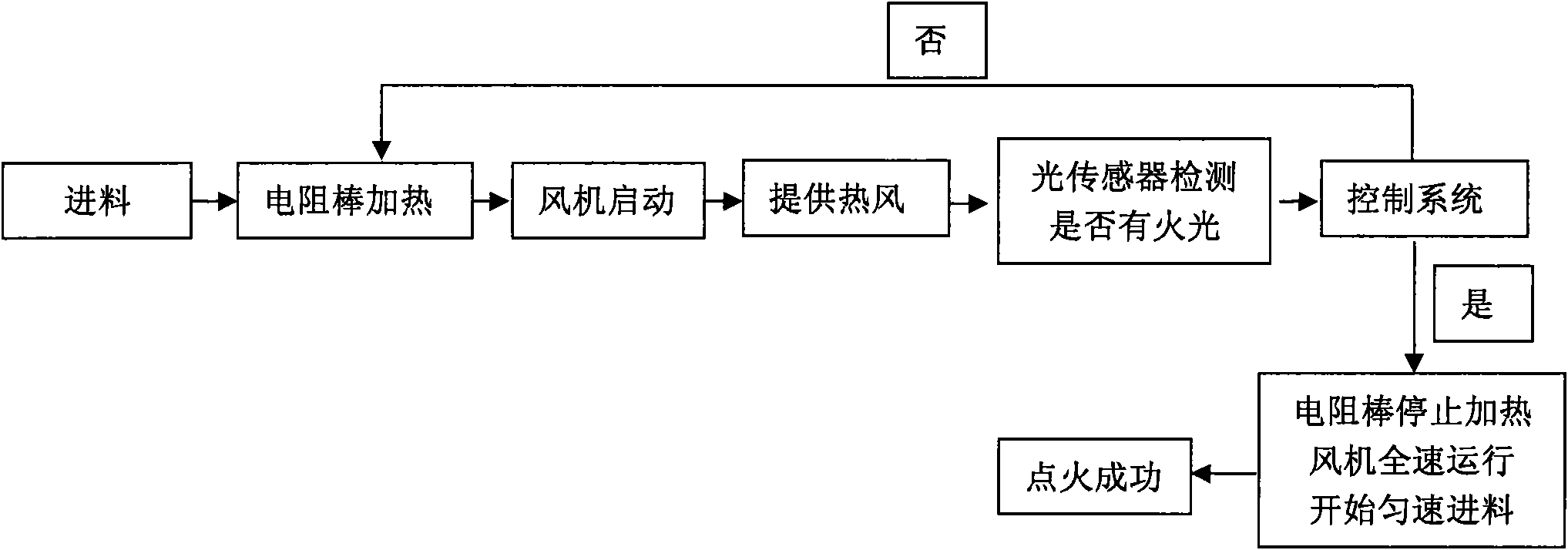

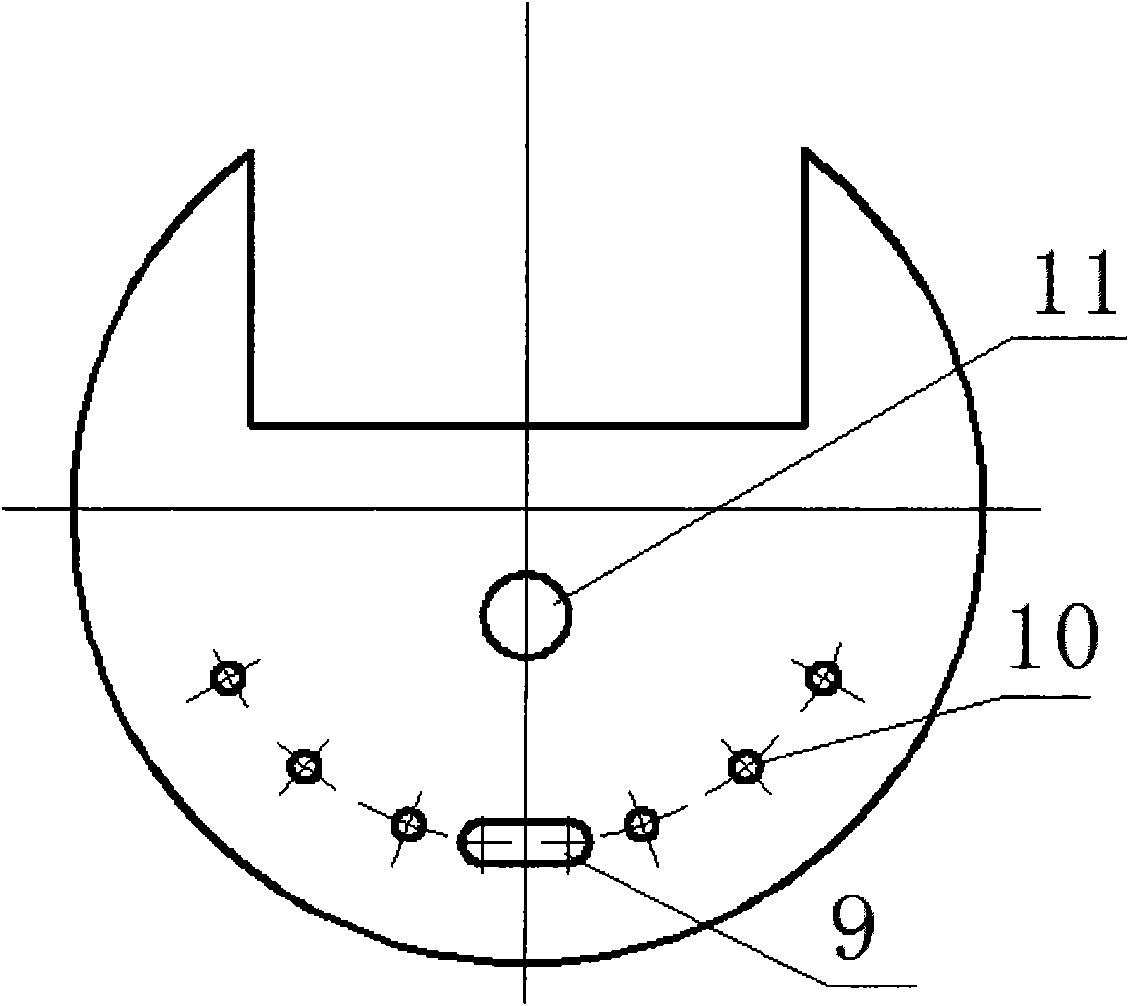

Automatic ignition method and device for biomass particle fuel

InactiveCN102466241ASolve the problem that it is difficult to collect feedback signalsIncrease flow rateIncandescent ignitionCombustion chamberRenewable energy technology

The invention discloses an automatic ignition method and an automatic ignition device for biomass particle fuel, which belong to the technical field of renewable energy sources. In the technical scheme, the automatic ignition device comprises a combustion chamber (1), a centrifugal blower (6) and an ignition mechanism (7); hot air is used for ignition in the ignition method, and the centrifugal blower (6) supplies high-temperature hot air to the inside of the combustion chamber (1) through the ignition mechanism (7) so as to heat the biomass particle fuel (2) in the combustion chamber; and in order to shorten ignition time and improve combustion efficiency, the centrifugal blower (6) supplies air to the combustion chamber (1) for three times, and photo-signals are acquired by a photo sensor (8) and fed back to a control system (5) so as to realize automatic ignition. By the automatic ignition method and the automatic ignition device for the biomass particle fuel, the problems of difficulty in ignition, low combustion efficiency and the like of the biomass particle fuel are solved, and support is provided for the combustion technology of the biomass particle fuel.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

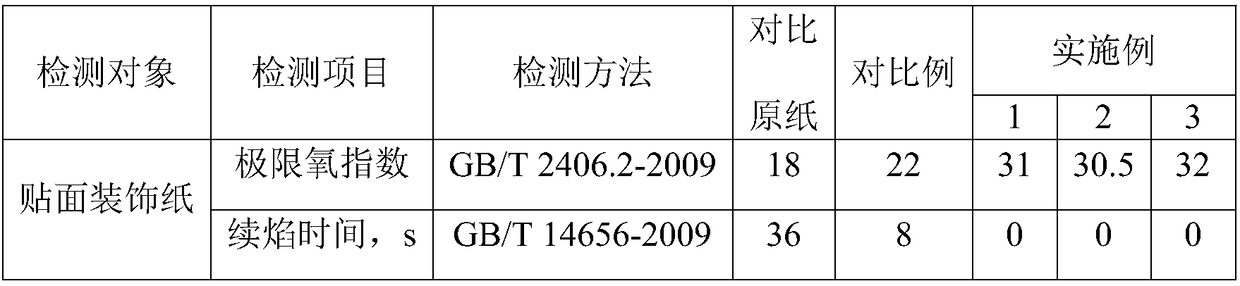

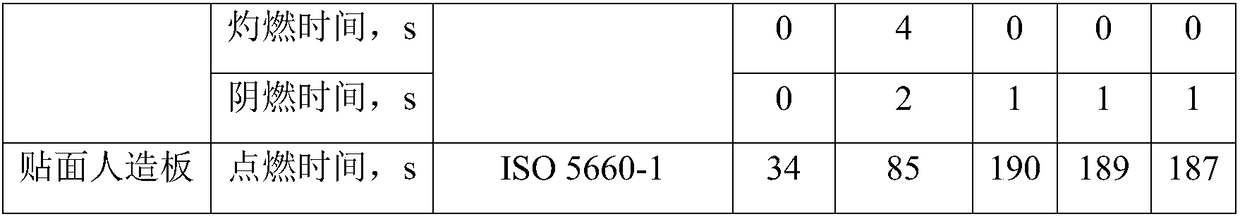

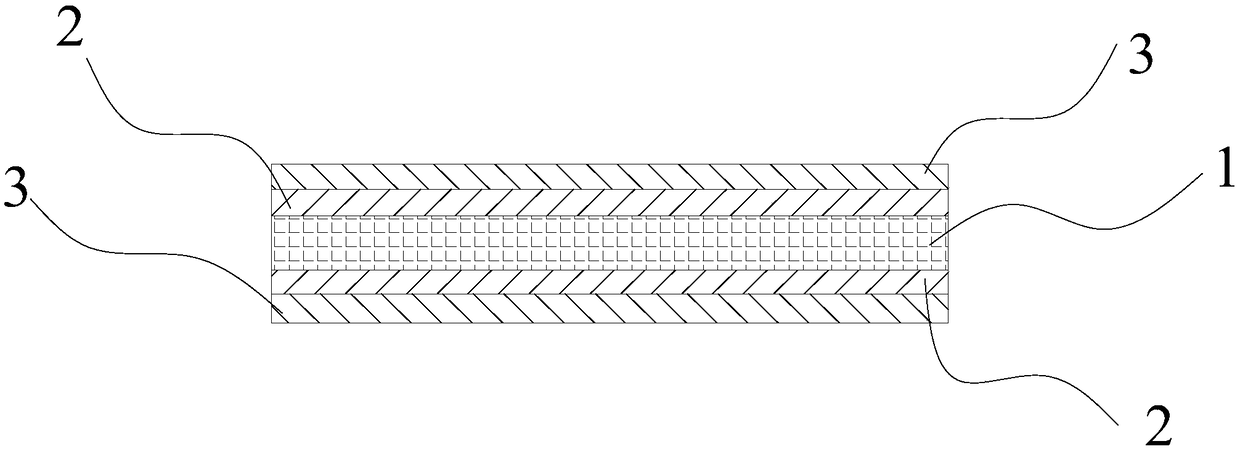

Veneering decorative paper having flame-retardant effect and flame-retardant veneering artificial board using same

ActiveCN108130808AFlame retardantIncrease temperatureSpecial paperWater-repelling agents additionLimiting oxygen indexPulp and paper industry

The invention relates to veneering decorative paper having a flame-retardant effect and a flame-retardant veneering artificial board using the same. The veneer decorative paper is prepared by the following method: 1) taking needle leaf wood pulp and broad leaf wood pulp, respectively beating, mixing and defibering, adding a titanium dioxide dispersion liquid, a retention aid, a wet strength agentand modified starch paste, to prepare original paper; 2) carrying out double-side coating on the obtained original paper with silica sol to obtain modified paper A; (3) carrying out impregnation treatment on the modified paper A with a borax solution to obtain modified paper B; and 4) carrying out double-side coating and gluing on the modified paper B with a soybean protein glue liquid with the gluing amount of 12-15 g / m<2>, and then carrying out press polishing with a press polishing machine. The obtained veneering decorative paper makes a flame-retardant agent added to the paper by using silica sol coating and borax solution impregnating, so the limit oxygen index of the decorative paper and the ignition time of the veneering artificial board are improved, and a good effect on preventingthe expansion and spreading of fire is achieved. The decorative paper does not contain formaldehyde, can greatly reduce the formaldehyde release amount of the veneering artificial board, and is suitable for promotion and use.

Owner:佛山市板缘装饰材料有限公司

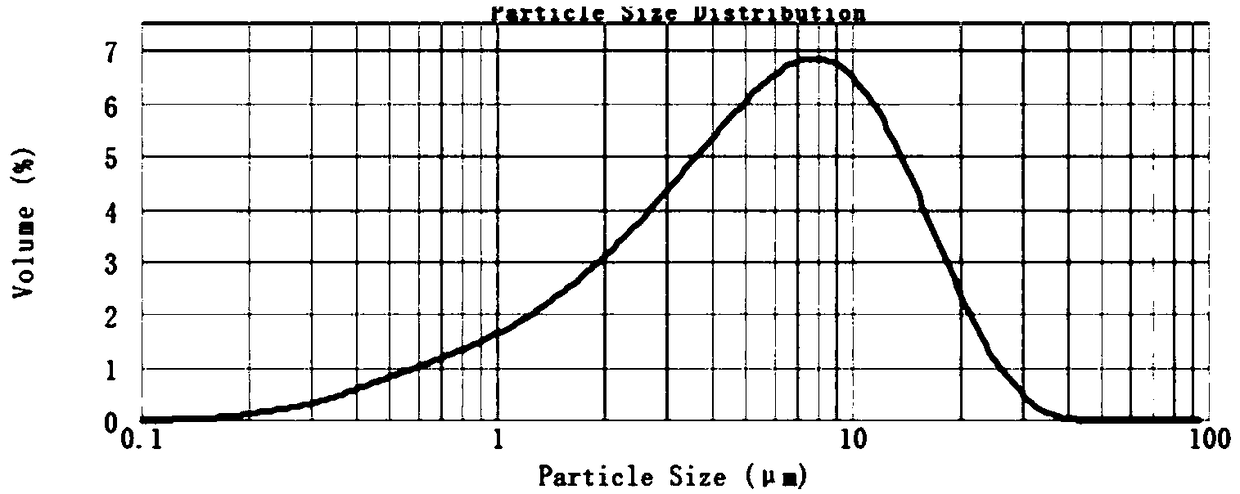

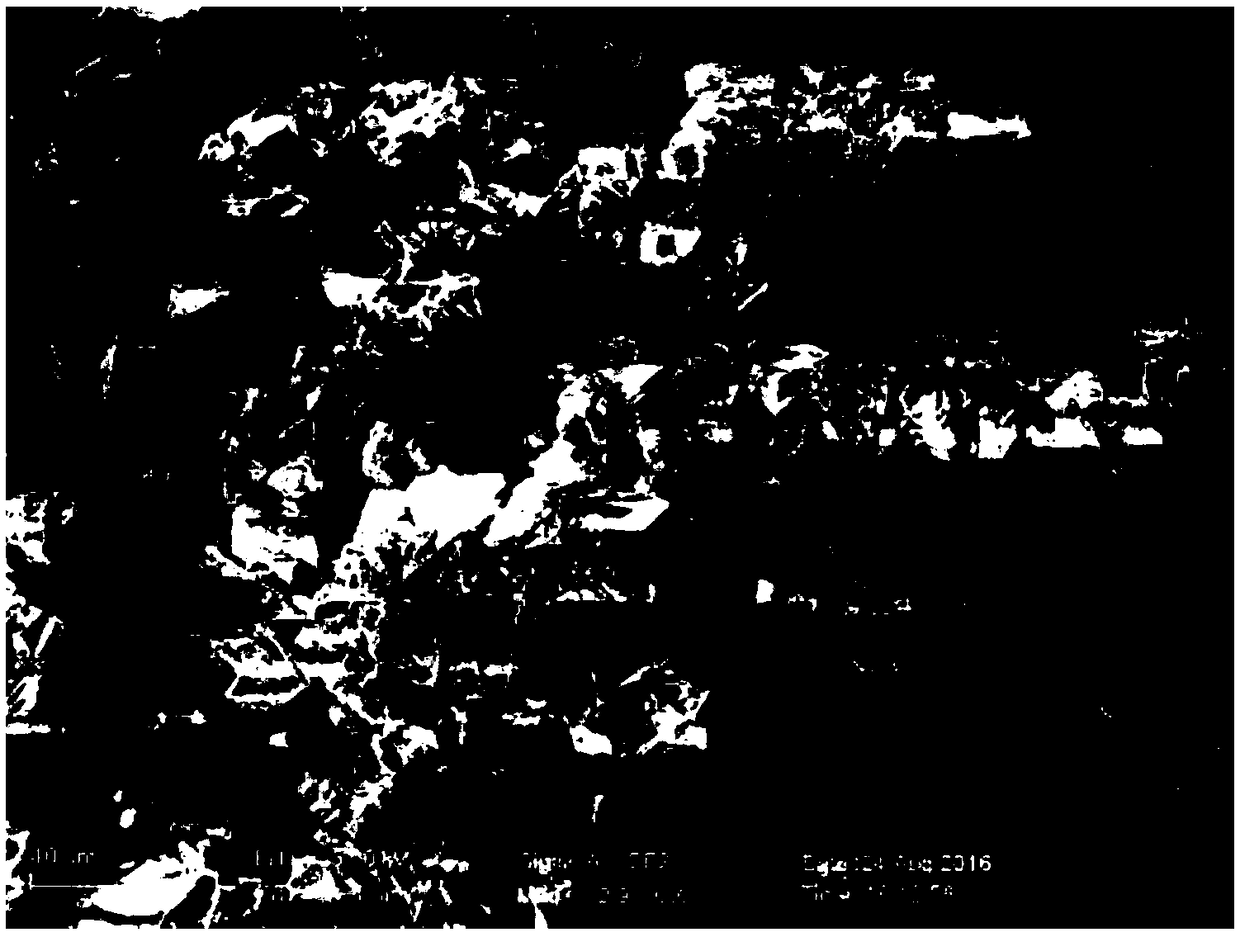

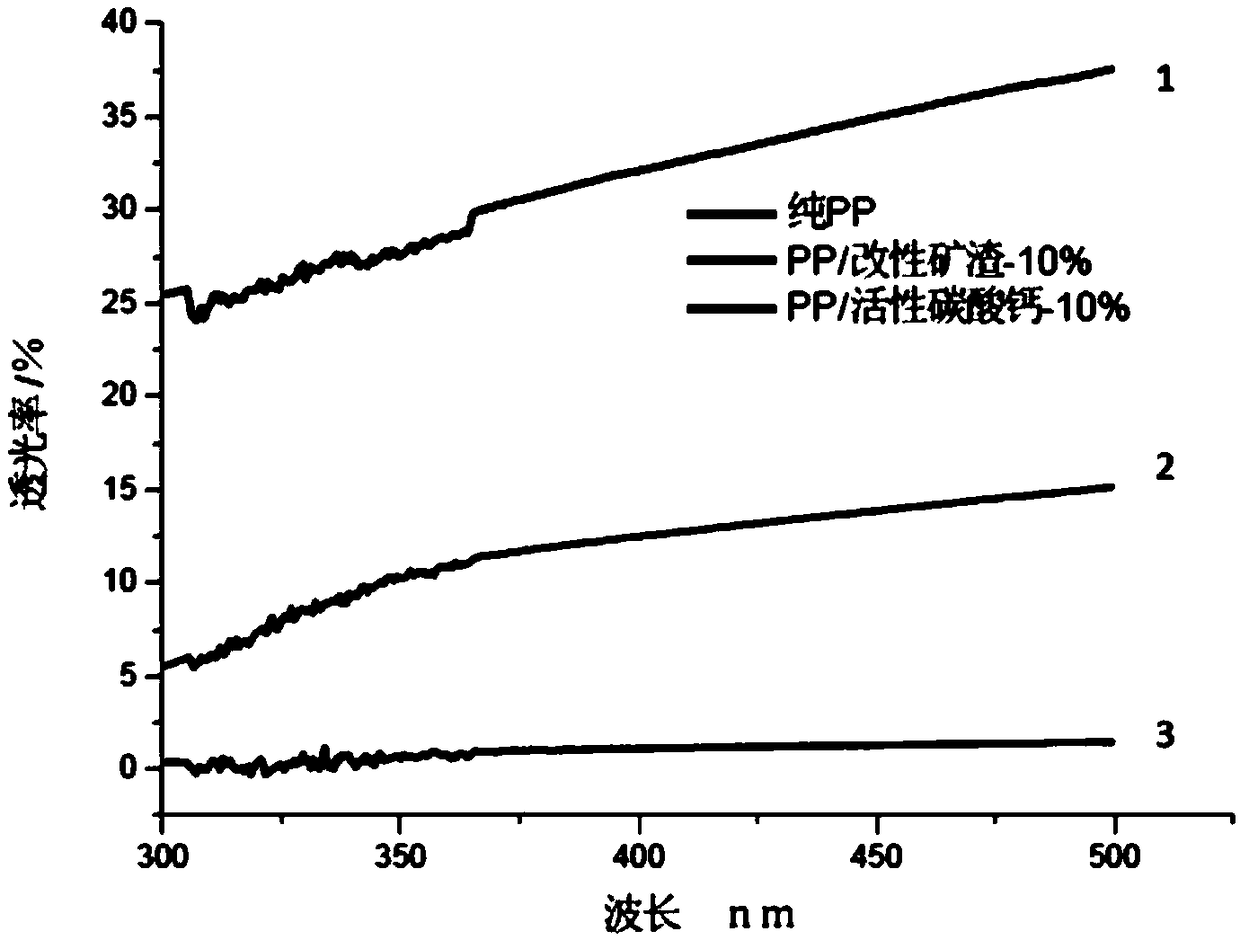

Mineral slag micropowder modified polypropylene composite and preparation method thereof

The invention discloses a mineral slag micropowder modified polypropylene composite and a preparation method thereof. The mineral slag micropowder modified polypropylene composite comprises the raw materials in percentage by mass: 1-10% of silane coupling agent, 1-30% of mineral slag micropowder and 60-98% of polypropylene, and the sum of the percentages of all the components is 100%. Known by combining with the tensile property, shock resistance, thermal property and optical property of a processed product, the comprehensive properties of the mineral slag micropowder serving as polypropylenefiller are obviously superior to those of activated calcium carbonate (1000 meshes) filler, and the prepared composite can be used in the fields such as polymers for the household appliance industry,polymers for automobile non-structural members and plastic pipelines for the home decoration industry.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +1

High-density fiberboard with high fire resistance and preparation method of high-density fiberboard

ActiveCN113070969AStrong fire resistanceImprove fire and flame retardant performanceWood working apparatusFlat articlesHigh densityMagnesium stearate

The invention belongs to the technical field of fiberboard materials, particularly relates to a high-density fiberboard with high fire resistance and a preparation method of the high-density fiberboard. The problems that in the prior art, a fiberboard can release harmful substances such as formaldehyde, the fiberboard belongs to an inflammable material are solved, and the high-density fiberboard comprises the following raw materials of, in parts by weight, 30-50 parts of wood chips, 30-50 parts of straws, 10-20 parts of light silicon dioxide, 3-5 parts of an adhesive, 3-5 parts of a flame retardant, 1-3 parts of magnesium stearate, 2-4 parts of hexamethyldisiloxane and 2-5 parts of p-hydroxybenzenesulfonic acid. According to the high-density fiberboard with the high fire resistance and the preparation method of the high-density fiberboard, the high-density fiberboard is scientific in formula and rigorous in proportion, the obtained high-density fiberboard has excellent fire-resistant and flame-retardant performance, waterproof and moistureproof performance and physical and mechanical performance, the preparation method of the high-density fiberboard is simple, mild in preparation condition and easy for industrial production, and can be widely applied.

Owner:佳诺威集团股份有限公司

Fireproof glass curtain wall

InactiveCN107325651AGood insulation performanceDelayed destructionFireproof paintsMaterial nanotechnologyFiberAluminium hydroxide

The invention relates to the technical field of curtain wall engineering, and discloses a fireproof glass curtain wall which is of a double-layer glass structure, wherein an air contact surface is coated by a fireproof thermal-insulating coating; glass gaps are filled with a thermal-insulating material; the fireproof thermal-insulating coating is prepared from the following components in parts by weight: 80-90 parts of a polychloroprene rubber emulsion, 40-50 parts of ethyl silicate, 30-40 parts of silica sol, 25-30 parts of pentaerythritol, 20-25 parts of aluminum hydroxide, 15-20 parts of an asbestos fiber, 10-15 parts of titanium dioxide, 5-10 parts of antimonous oxide and 1-2 parts of nano zinc oxide; the thermal-insulating material is a micro-pore material prepared from phosphate, germinate and silicate via mixing. The high temperature resistance and the thermal impact resistance of the fireproof glass curtain wall are improved, the wall can endure a temperature difference up to 600 DEG C without cracking in case of fire hazard, and thus the fire hazard damage can be minimized.

Owner:合肥皖水信息科技有限公司

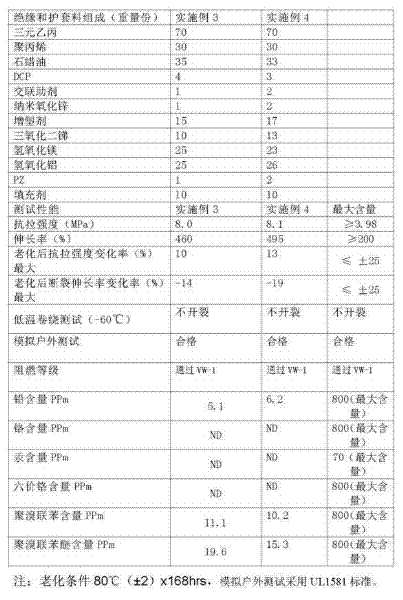

High flame retardant super low temperature resistant environmental flexible cable

ActiveCN102262936AImprove anti-agingGood heat and cold resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlasticizer

The invention relates to the technical field of novel material application, in particular to an environment-friendly flexible cable with high flame retardance and super low temperature resistance. The environment-friendly flexible cable with the high flame retardance and the super low temperature resistance comprises a flexible twisted conductor, an insulating layer and an outer protective layer, wherein the insulating layer is wrapped outside the flexible twisted conductor to form single insulated wires; the outer protective layer wraps at least two single insulated wires; the insulating layer and the outer protective layer are made from the same materials, take an ethylene-propylene-diene monomer as a disperse phase and take polypropylene as a continuous phase; the insulating layer contains a plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant; and the outer protective layer contains the plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant. Due to the adoption of the technical scheme, the environment-friendly flexible cable with the high flame retardance and the super low temperature resistance has high torsion resistance, the super low temperature resistance and flame retardance, is difficult to age and crack and environment-friendly, and can work stably in low temperature environments of below -60 DEG C.

Owner:GUANGDONG ZHONGDE CABLE

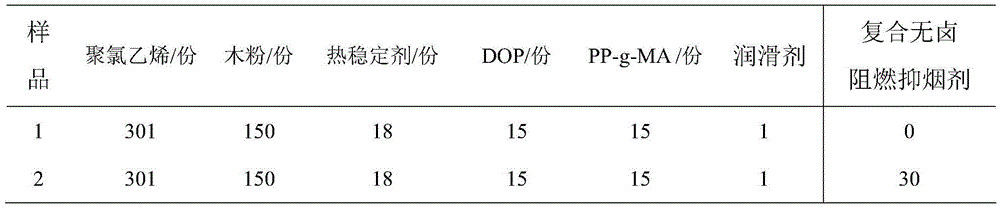

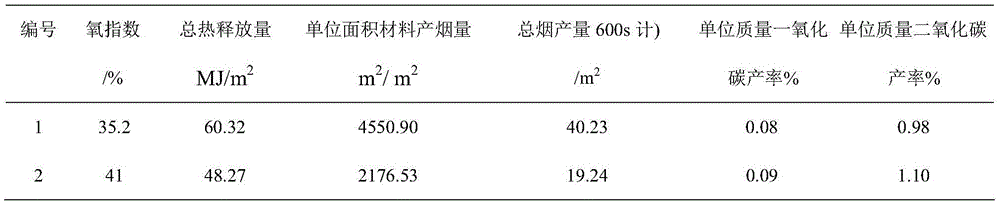

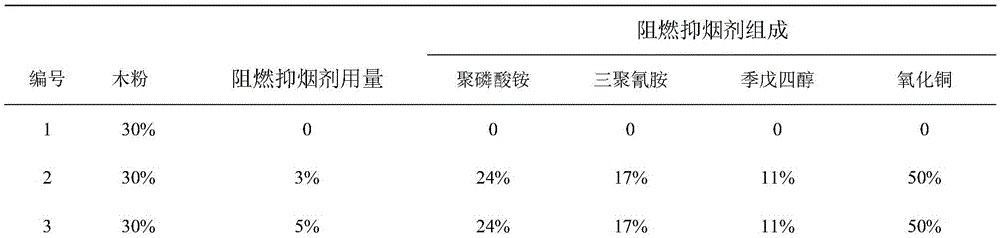

Composite halogen-free flame-retardant smoke suppression agent of PVC wood-plastic composite material and preparation method and application of agent

InactiveCN105566811AAdvantages of flame retardant and smoke suppression effectAdd lessPentaerythritolCombustion

The invention relates to a composite halogen-free flame-retardant smoke suppression agent of a PVC wood-plastic composite material and a preparation method and application of the agent, which relate to the composite halogen-free flame-retardant smoke suppression agent and the preparation method and application of the agent, and aim at solving the problems that the PVC wood-plastic composite material is combustible, a great amount of smoke is produced when the composite material is combusted, the addition amount of the existing PVC wood-plastic composite material flame-retardant smoke suppression agent is large, the flame-retardant effect and the smoke suppression effect are poor, and the existing PVC wood-plastic composite material flame-retardant smoke suppression agent is harmful to the health of people. The composite halogen-free flame-retardant smoke suppression agent consists of ammonium polyphosphate, melamine, pentaerythritol and copper oxide. The preparation method comprises the following steps: I, preparing an expansion-type flame-retardant agent; II, preparing the composite halogen-free flame-retardant smoke suppression agent. The application method comprises the following steps: I, weighing raw materials; II, preparing high-temperature materials; III, preparing a premix; IV, extruding and forming. The flame-retardant smoke suppression agent solves the problems that the wood-plastic composite material is combustible, a great amount of smoke is produced when the composite material is combusted, the addition amount of the existing flame-retardant smoke suppression agent is large, the effect is poor, and the existing flame-retardant smoke suppression agent is harmful to the health of people. The composite halogen-free flame-retardant smoke suppression agent is used for resisting the combustion and suppressing the smoke of the PVC wood-plastic composite material.

Owner:白晓艳

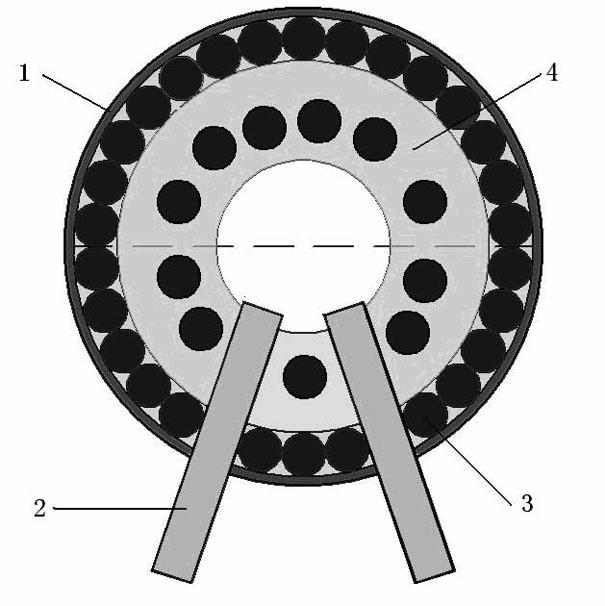

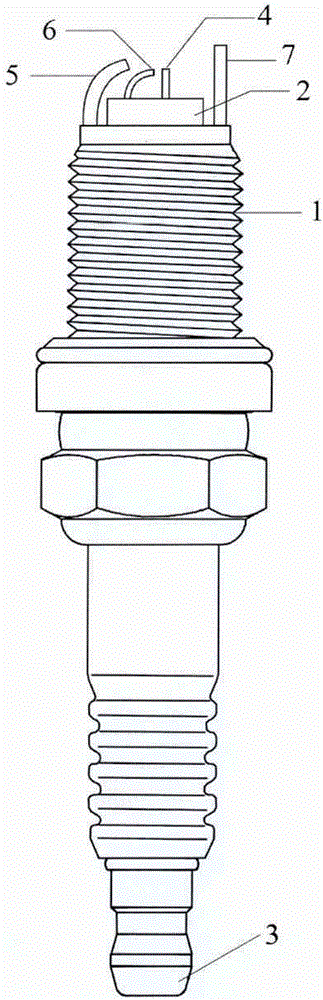

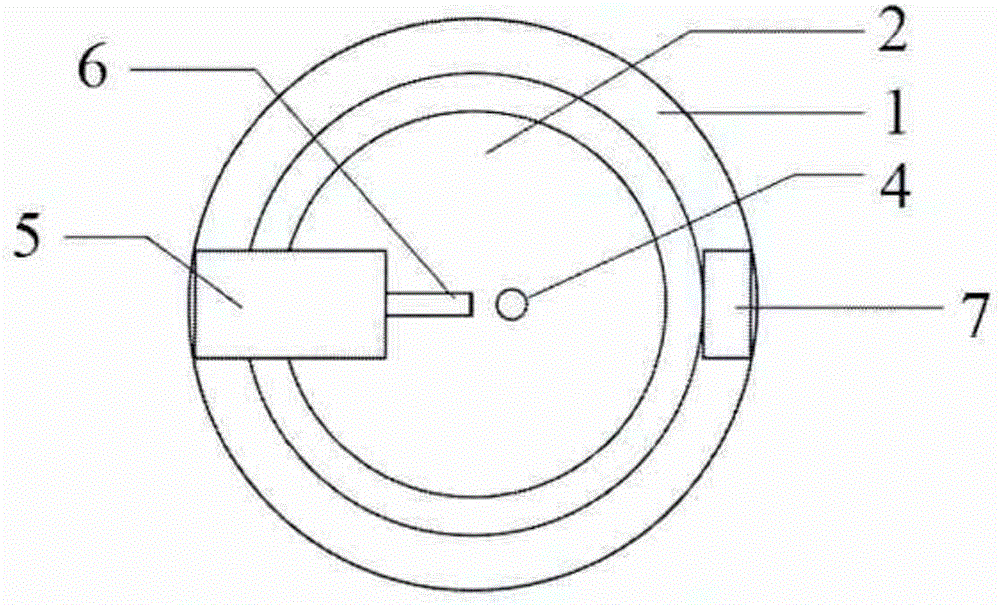

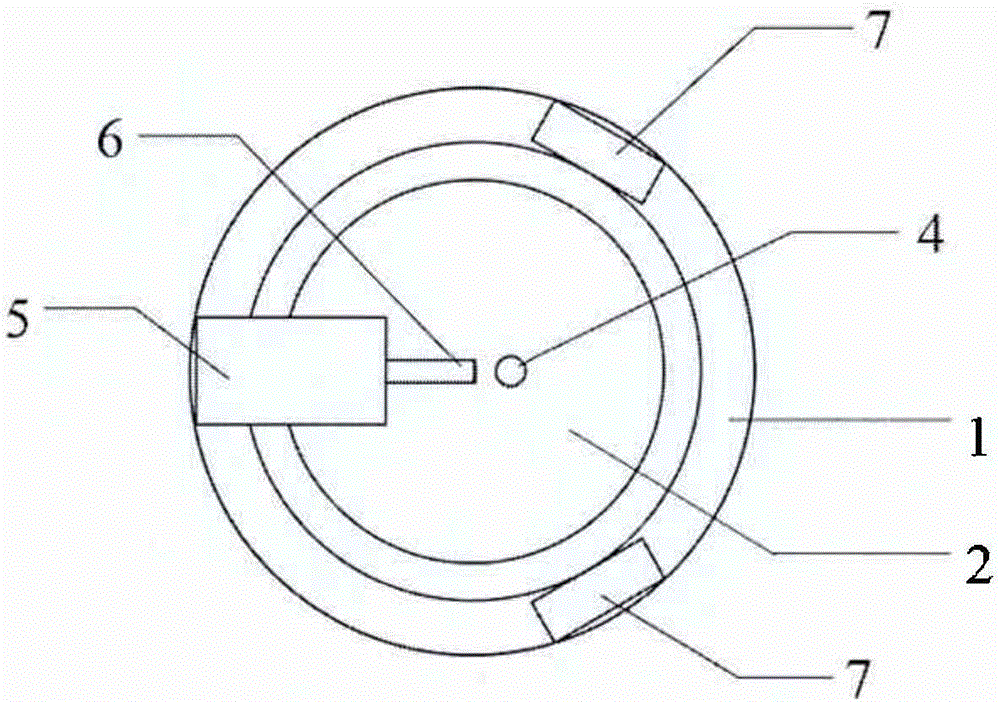

Multi-electrode sparking plug

The invention discloses a multi-electrode spark plug, comprising a metal shell, one end of the metal shell is provided with a ceramic insulator penetrating through the metal shell, a working side electrode and a guard electrode are provided, and the ceramic insulator passes through the metal shell One end of the ceramic insulator is provided with a wire nut, and the other end is provided with a center electrode and a suspension electrode. The center electrode and the wire nut are connected inside the ceramic insulator, and the ceramic insulator is provided with a suspension electrode. The suspension electrode is located between the center electrode and the side electrodes, and the metal shell, the center electrode and the side electrodes are not in contact with the suspension electrodes. The multi-electrode spark plug of the present invention can realize two ignitions, prolong the ignition time, make the fuel burn more fully, improve the efficiency of the engine, reduce harmful tail gas emissions, and reduce fuel consumption.

Owner:上海极燃汽车科技有限公司

Preparation method of environment-friendly flame-retardant case for computer

The invention discloses an environment-friendly flame-retardant case for a computer and a preparation method thereof. The case is prepared from the following raw materials in parts by weight: 10 to 15parts of carbon fiber, 20 to 40 parts of EVA resin, 6 to 10 parts of aluminum hydroxide, 6 to 10 parts of magnesium hydrate, 3 to 5 parts of nylon particles, 1 to 3 parts of zinc hydroxystannate, 3 to 5 parts of ammonium phosphate, 6 to 10 parts of montmorillonoid and 1 to 2 parts of plasticizers. The environment-friendly flame-retardant case for the computer is strictly controlled; the production process parameters and the proportion of all ingredients of the computer case are strictly controlled; the nylon particles and ammonium phosphate particles are added into the raw materials; the heatrelease rate is reduced, so that the original ignition time is prolonged; the zinc hydroxystannate is added into the machine materials, so that the flame retardant and smoke suppression performance of the material can be obviously improved; the montmorillonoid material is added, so that the tensile strength and the flame retardant performance of the material are improved; the environment-friendlyflame-retardant case is suitable for being widely popularized.

Owner:河南云投小镇创业孵化器有限公司

Flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate

InactiveCN109517291AGood oil resistanceImprove heat aging resistancePolyvinyl chlorideChlorinated paraffins

The invention discloses a flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate. The flame retardance heat aging resistant PVC foaming trough plate comprises the following raw materials in parts by weight: 60-70 parts of polyvinyl chloride, 10-28 parts of nitrile rubber, 5-13 parts of chlorinated polyethylene rubber, 4-9 parts of a thermoplastic polyurethane elastomer, 5-11 parts of polyamic acid, 2-8 parts of alpha-zirconium phosphate, 5-8 parts of attapulgite, 2-7 parts of muscovite, 3-9 parts of bamboo powder, 8-17 parts of composite foaming agent, 4-11 parts of flame retardant, 0.3-1 part of an aluminum-titanium composite coupling agent, 0.3-1.2 parts of dicumyl peroxide, 0.2-1.3 parts of sulfur, 1.7 parts of an accelerant, 15-30 parts of dioctyl phthalate, 2-9 parts of chlorinated paraffin, 1-3 parts of phenyl phosphorus dichloride, 3-5 parts of resorcinol, and 2-3 parts of a composite heat stabilizer. The flame retardance heat aging resistant PVC foaming trough plate provided by the invention has good heat aging resistance, excellent flame retardance and long service life.

Owner:安徽优丽普科技有限公司

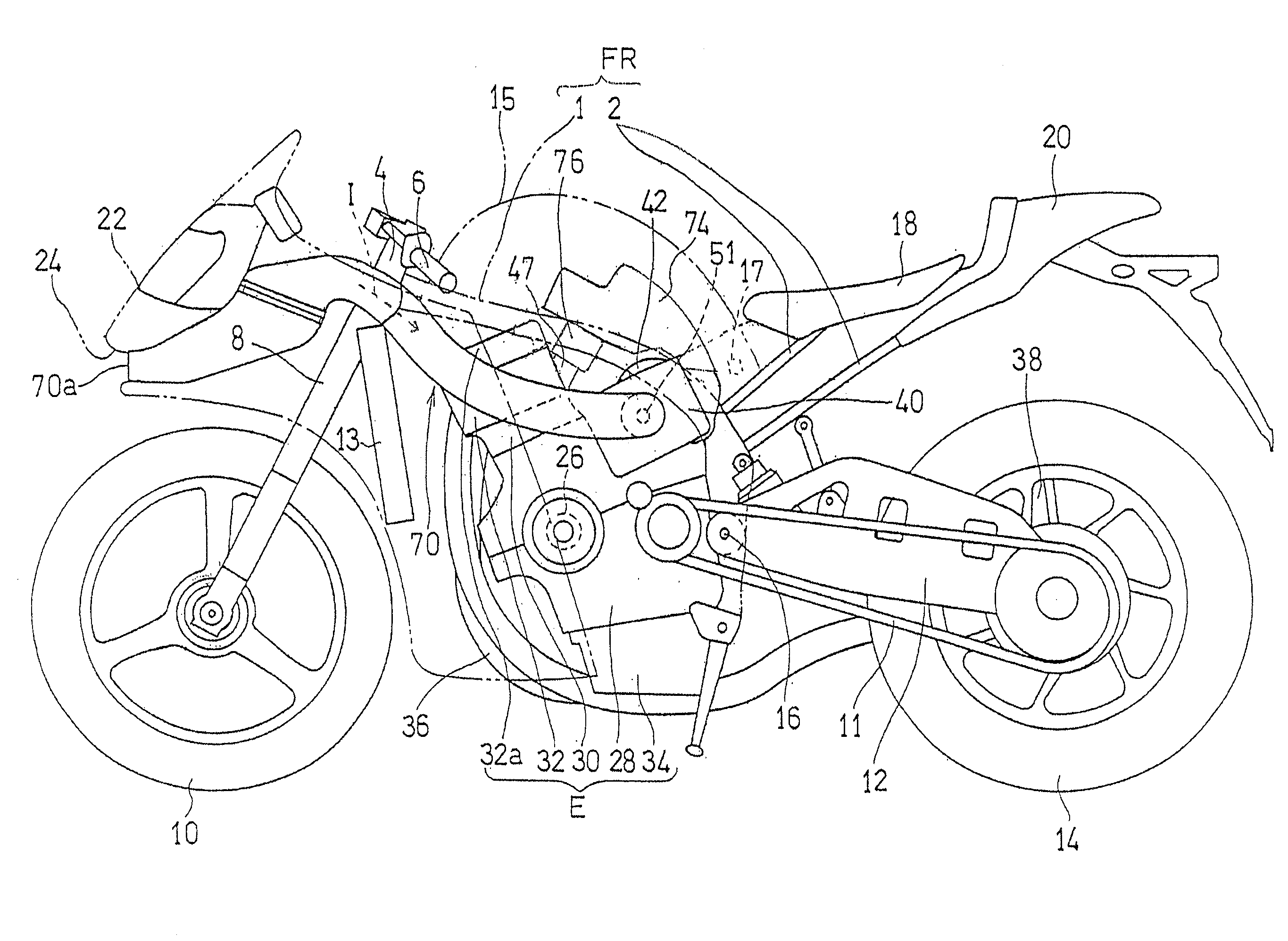

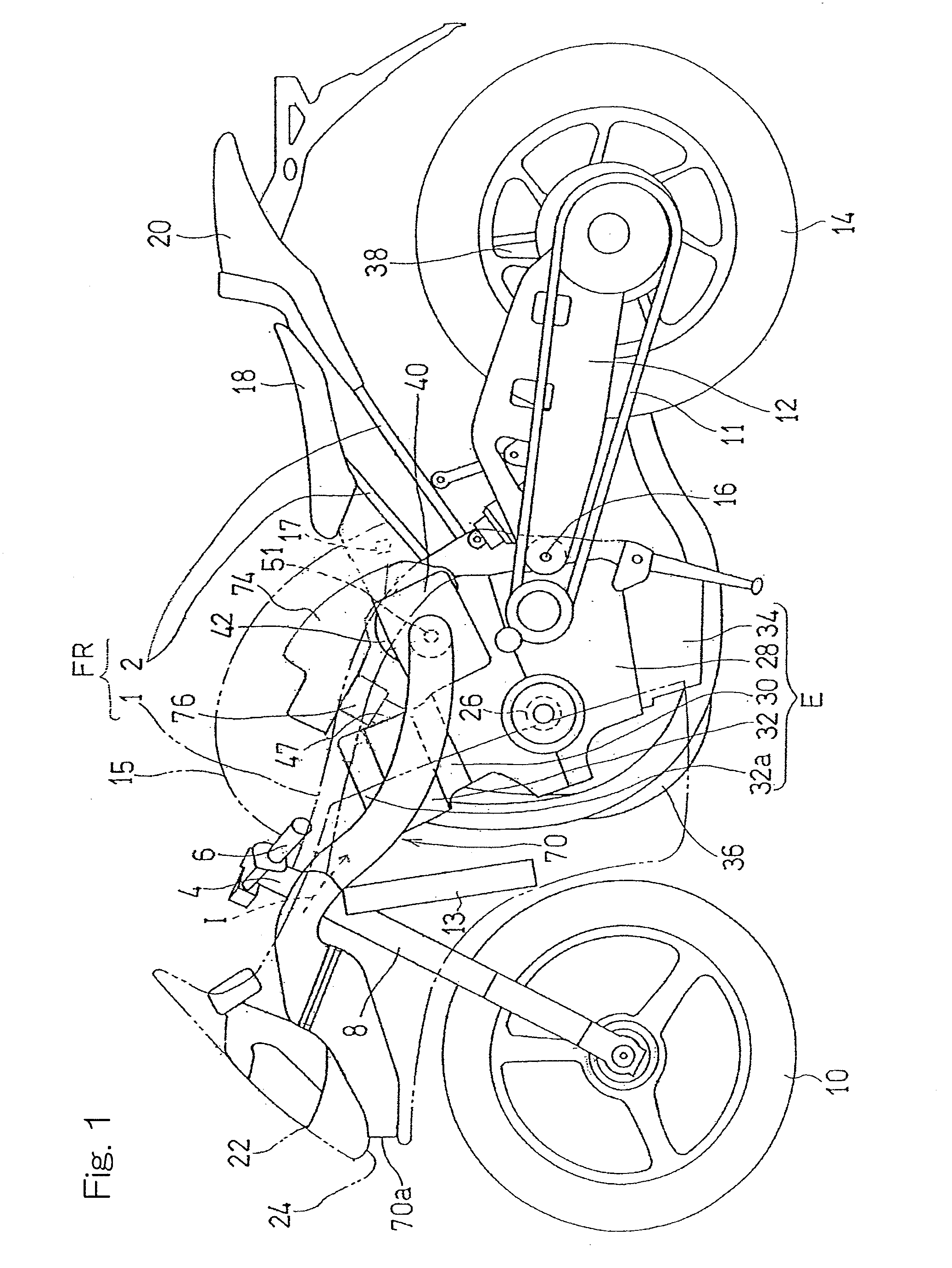

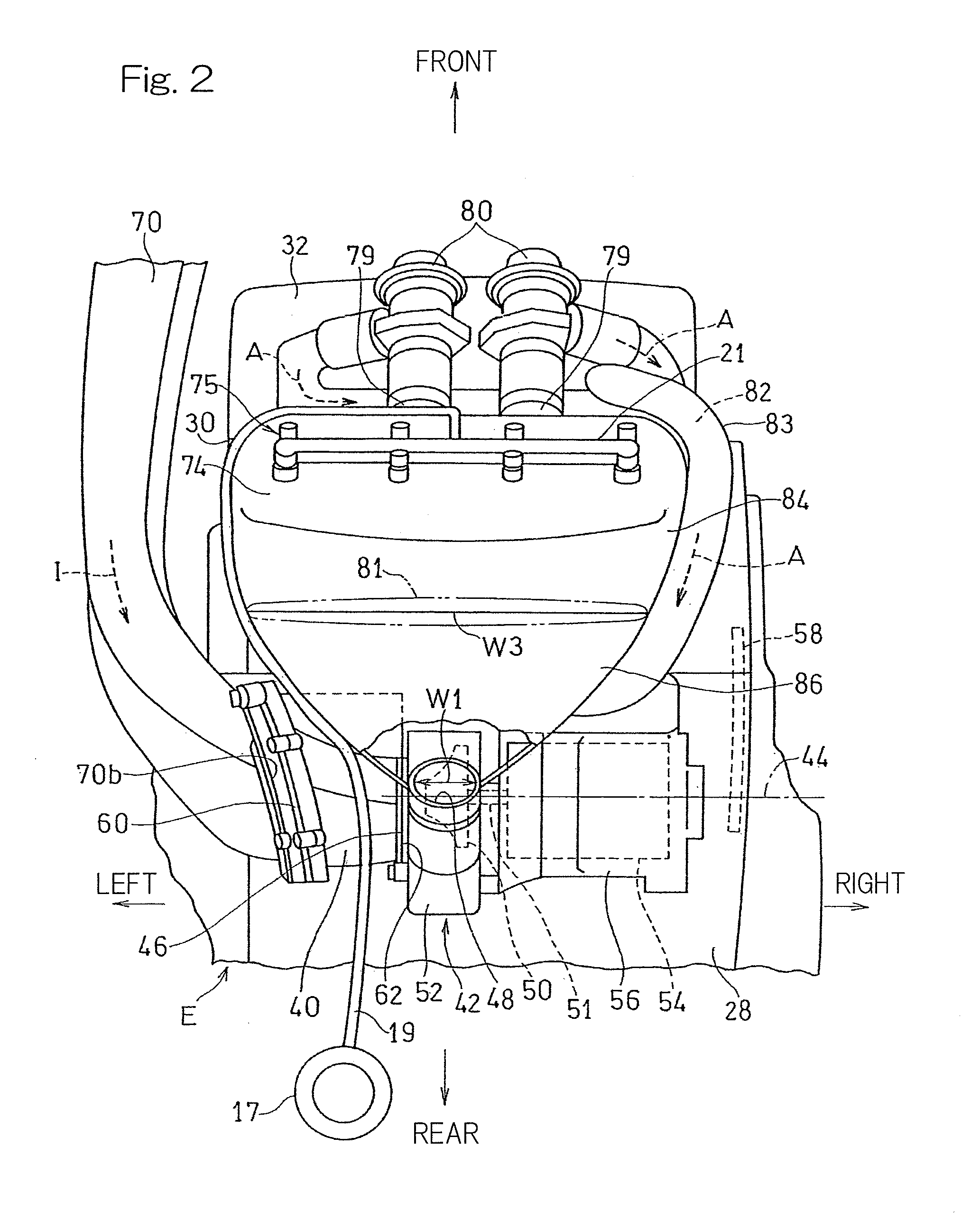

Air intake chamber for saddled vehicle

ActiveUS20160061163A1Increase productionSolve insufficient capacityInternal combustion piston enginesAir intakes for fuelInterior spaceCombustion

A motorcycle includes a supercharger to pressurize an intake air and supplying it to a combustion engine and an air intake chamber disposed downstream of the supercharger. The air intake chamber is made of a metallic material and has a capacity of an interior space thereof which is within the range of three to eight times the displacement of the combustion engine. The dimension from an upstream end portion on an inlet side of the interior space of the air intake chamber to a downstream end portion on an outlet side of the interior space of such air intake chamber is chosen to be three or more times the inner diameter of an outlet.

Owner:KAWASAKI MOTORS LTD

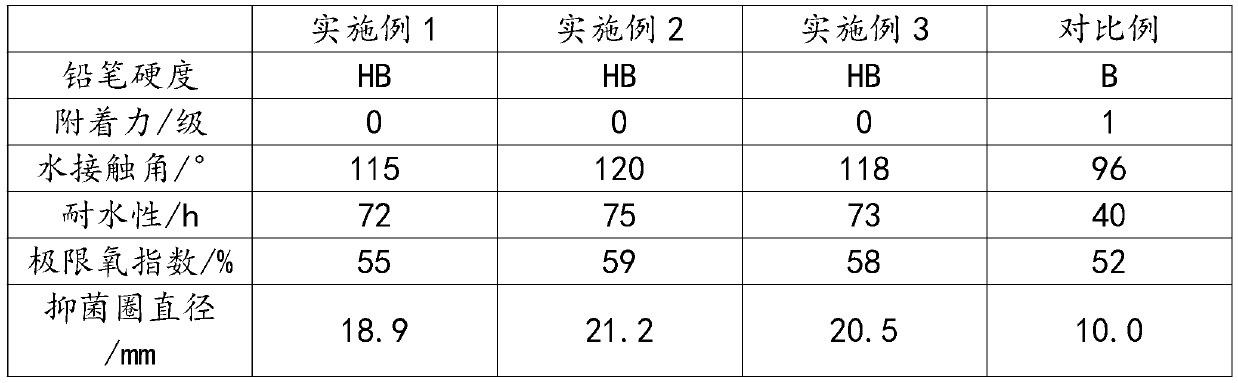

Smoke-suppressing flame-retardant wood composite material and preparation method thereof

PendingCN113717488AImprove mechanical propertiesImprove fire and flame retardant performanceAntioxidantWood flour

The invention relates to the field of building materials, in particular to a smoke-suppressing flame-retardant wood composite material and a preparation method thereof. The smoke-suppressing flame-retardant wood composite material is prepared from modified wood flour, a phenolic resin / ammonium polyphosphate / molybdenum compound composite material, polyethylene, maleic anhydride grafted polyethylene, nanocellulose, halloysite nanotubes, dicumyl peroxide and an antioxidant; The smoke-suppressing flame-retardant wood composite material is good in mechanical properties, excellent in fireproof and flame-retardant performance, long in ignition time, not prone to combustion and small in heat and smoke production during combustion, can be widely applied to the fields of home building materials and decoration and has excellent market application prospects.

Owner:桃江县大丰木业有限责任公司

Windproof lighter

InactiveCN104048322ATake advantage ofNot easy to turn offIncandescent ignitionRechargeable cellSmoke Emission

The invention relates to a windproof lighter which comprises a shell body. A lighter cover is arranged on the shell body. A rechargeable battery, a heating assembly and a switch are further arranged in a windproof lighter body. The heating assembly is arranged below the lighter cover, and the whole heating assembly is a cylinder. The windproof lighter further comprises a USB interface which is arranged at the bottom of the shell body, and the upper portion, surrounding the periphery of the heating assembly, of the shell body is provided with a windproof hood. According to the technical scheme, through arrangement of a windproof device, long firing time is further guaranteed, the problem that ignition is prone to extinguishing is solved; a lighting device is arranged, so that in a poor light environment, the lighting device which is similar to a flashlight can be turned on, and the windproof lighter is very practical; a smoke absorbing device is arranged for absorbing the smoke generated in the smoking process, and thus influences on the environment and other people are reduced.

Owner:王玲玲

Nylon composite for bearing pedestal

The invention discloses a nylon composite for a bearing pedestal, which is characterized in that the nylon composite comprises the following components in percentage by weight: 80 to 93.5 percent of nylon base material, 4 to 9 percent of decabromodiphenyl ether, 1 to 4 percent of antimonous oxide, 0.5 to 2 percent of zinc borate and 1 to 5 percent of carbon black. The invention has high strength and high toughness as well as waterproof performance and flame retardant property.

Owner:邵峰

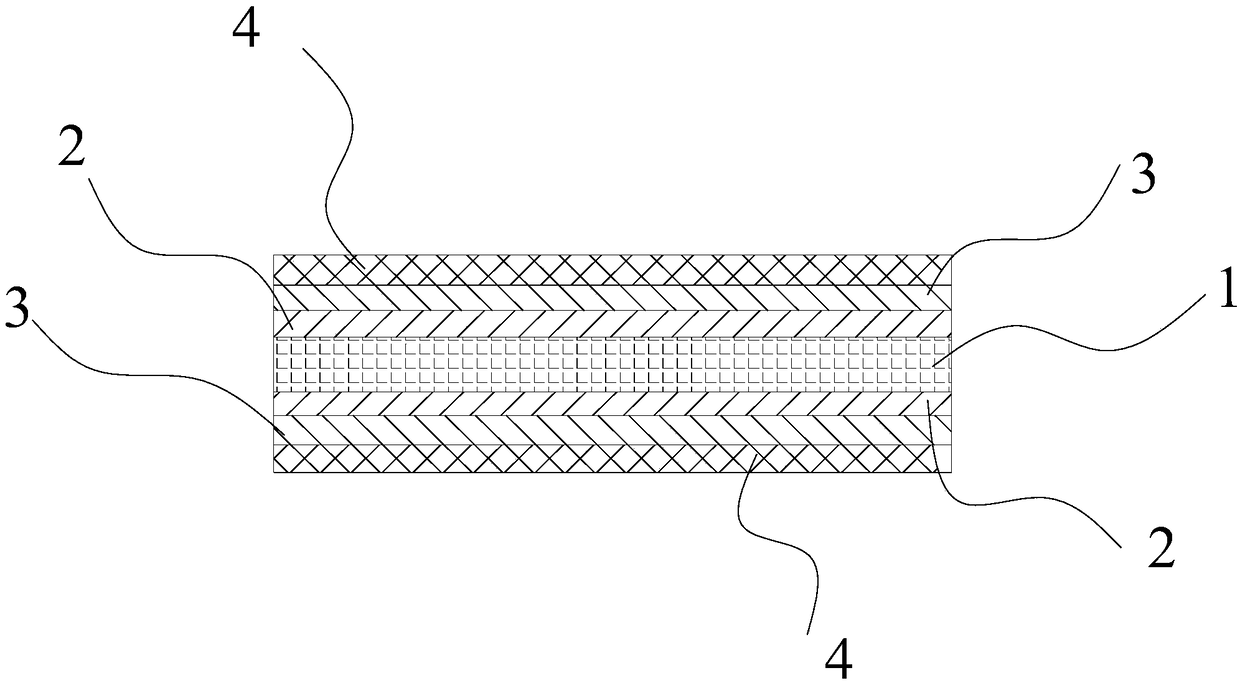

Coated fabric for liquid bag and preparation method thereof

The invention provides a coated fabric for a liquid bag. The coated fabric comprises a base fabric, first coatings and second coatings. The base fabric is made by blending sea-island fibers and polyester fibers, a first coating is respectively arranged on both sides of the base fabric, and a second coating is disposed at the end of each first coating. Each first coating material includes the following raw materials: polyvinyl chloride paste resin, plasticizer, paraffin, epoxidized soybean oil, heat stabilizer, ultrafine calcium carbonate, nano calcium carbonate, adhesive, antimold, halogen-free phosphorus flame retardant and ammonium molybdate. Each second coating includes the following materials: polyvinyl chloride paste resin, plasticizer, paraffin, epoxy soybean oil, heat stabilizer, ultrafine calcium carbonate, nano calcium carbonate, antimold, halogen-free phosphorus flame retardant and ammonium molybdate. A preparation method of the coated fabric for the liquid bag is further provided. The coated fabric is free of pollution in the processing process, is an environment-friendly product, has the advantages of good wear resistance, long service life, high acid and alkali corrosion resistance, excellent processing performance and the like, and can be widely used for the liquid bag of various liquids.

Owner:ANHUI PLATO COATED FABRICS

Preparation method of corrugated paper with flame-retardant effect

InactiveCN111634098AImprove permeabilitySuppress generationFlexible coversWrappersCardboardCarbon layer

The invention discloses a preparation method of corrugated paper with a flame-retardant effect, and relates to the technical field of corrugated boards. The corrugated paper is obtained by compoundingthree surface paper plates and two corrugated plates. The corrugated paper prepared by the method has good edge pressure strength; and a certain amount of melamine cyanurate is added, so that the thermal stability and charring performance of the flame-retardant corrugated paper at high temperature can be further improved. The melamine cyanurate and the magnesium hydroxide have a synergistic effect, so that a compact expanded carbon layer can be formed on the surface, and the effects of heat insulation and oxygen insulation are effectively exerted, thereby enhancing the flame retardancy of thecorrugated paper.

Owner:马鞍山市康辉纸箱纸品有限公司

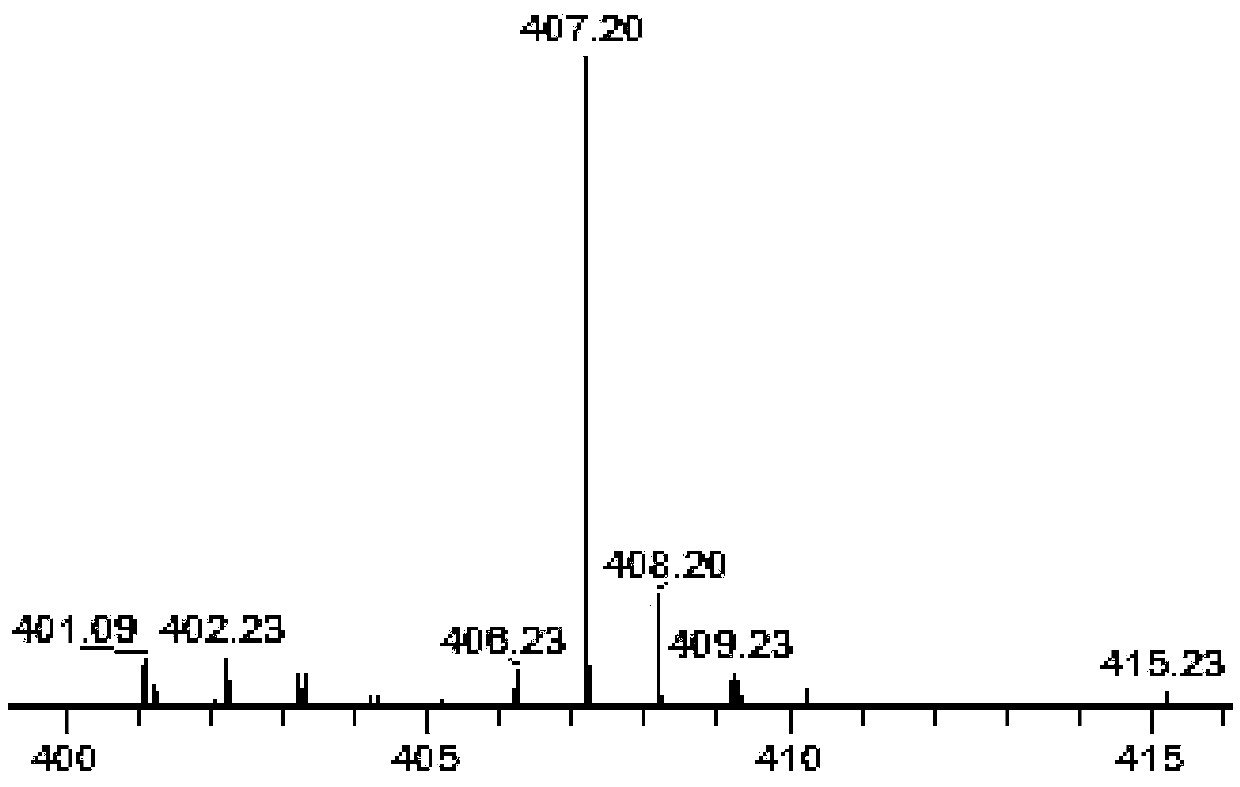

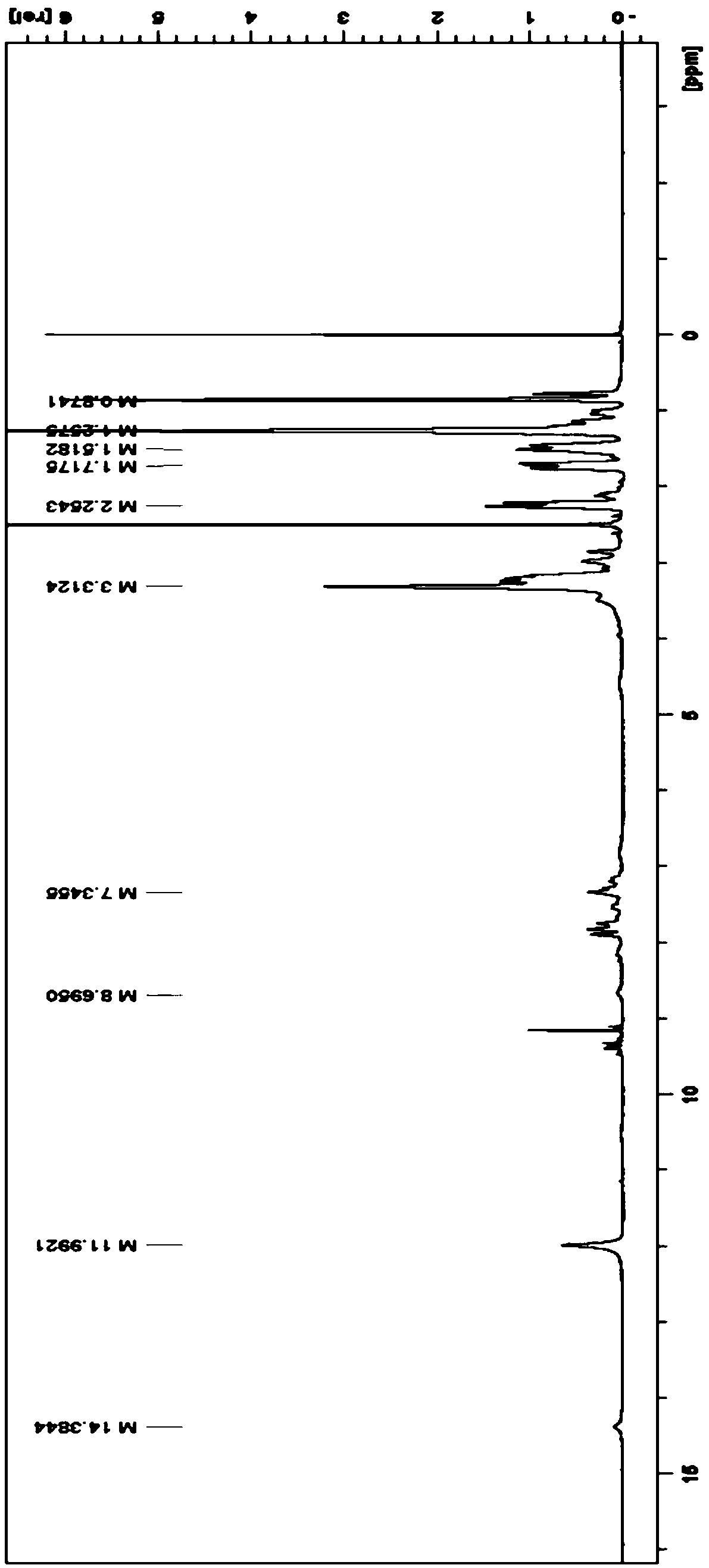

Wood modifying agent with surface activity as well as preparation method and application thereof

InactiveCN109676729AHigh flame retardant efficiencyGood smoke suppression effectWood treatment detailsWood impregnation detailsChemistryFire retardant

The invention relates to the technical field of wood modification, and particularly relates to a wood modifying agent with surface activity as well as a preparation method and application thereof. Thewood modifying agent with the surface activity is of a structure as shown in a formula I as shown in the specification. The wood modifying agent with the surface activity comprises flame retarding nitrogen and sulphur, a hydrophobic fat chain and a hydrophilic carboxyl, so that the hydrophily of the wood is reduced, and the shortages of low hydrophobic function and easy loss of the modifying agent are overcome; the modifying agent has the advantages of being high in flame retarding efficiency, good in smoke inhibiting effect, high in hydrophobic performance and resistant to loss, and is a multifunctional wood flame retarding agent. Additionally, the use performance and the color of the wood are not influenced after the wood modifying agent with surface activity is added to the wood. The invention also provides the preparation method of the wood modifying agent with the surface activity; the synthesis processes is simple and convenient, raw materials are easy to obtain, and the methodis easy to popularize.

Owner:ZHONGBEI UNIV

Coated cloth for car covering

InactiveCN108842470AExcellent overall performanceGood folding resistanceRoad vehiclesTextiles and paperThermoplasticPlasticizer

The invention provides a coated cloth for car covering, which comprises a base cloth, antimicrobial coatings coated on the upper and the lower surfaces of the base cloth, first coatings coated on theouter surfaces of the antimicrobial coatings and second coatings coated on the outer surfaces of the first coatings, wherein the first coatings adopt polyvinyl chloride paste resin, a plasticizer, a modified ultraviolet absorbent, thermoplastic wires, a thermal stabilizer, ultra-fine calcium carbonate, nanometer calcium carbonate, an adhesive, a halogen-free phosphorus flame retardant, ammonium molybdate, hollow micro glass beads and hollow ceramic powder as raw materials, and the second coatings adopt the polyvinyl chloride paste resin, the plasticizer, the modified ultraviolet absorbent, thethermoplastic wires, the thermal stabilizer, the ultra-fine calcium carbonate, the nanometer calcium carbonate, the halogen-free phosphorus flame retardant, the ammonium molybdate, the hollow micro glass beads and the hollow ceramic powder as the raw materials. The invention also provides a preparation method of the coated cloth for car covering. The invention not only has good folding endurance,but also has the advantages of anti-bacteria, anti-fungus, durable use, low cost, and the like.

Owner:ANHUI PLATO COATED FABRICS

Xylem filber-polyvinyl chloride composite material and method for producing the same

Owner:NORTHEAST FORESTRY UNIVERSITY

Waterproof coating for surface of wooden furniture and preparation method of waterproof coating

InactiveCN110760230AImprove thermal stabilityUniform particle size distributionFireproof paintsAntifouling/underwater paintsPolymer sciencePolymer chemistry

The invention discloses a waterproof coating for the surface of wooden furniture. The waterproof coating is prepared from the following raw materials: in parts by weight, 50-60 parts of a modified styrene-acrylic emulsion, 4-6 parts of inorganic filler, 0.8-1 part of a flame retardant, 1-2 parts of a defoamer, 0.5-0.6 part of a leveling agent, 1-1.5 parts of a wetting agent and 10-14 parts of deionized water. The invention also discloses a preparation method of the waterproof coating. The modified styrene-acrylic emulsion is adopted as a film-forming material for the coating, a styrene-acrylicemulsion is modified by polysiloxane, and therefore the obtained film-forming substrate not only has excellent waterproof performance, but also has heat resistance and bacteriostasis; through addition of the flame retardant which is a compound to the coating, the flame retardant properties can be developed from gas phase dilution, catalytic carbonization and different aspects, so that the coatinghas a good effect of flame retardancy; and then the waterproof coating with flame retardancy and bacteriostasis is prepared through auxiliary preparation of other additives, and is suitable for the wooden furniture, and the service life of the wooden furniture is improved.

Owner:安徽阜南县向发工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com