Automatic ignition method and device for biomass particle fuel

A biomass particle and automatic ignition technology, which is applied in the direction of combustion ignition, combustion method, incandescent ignition, etc., can solve the problems of difficult ignition and high pollutant emissions, and achieve the effects of facilitating ignition, improving combustion efficiency, and increasing ignition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

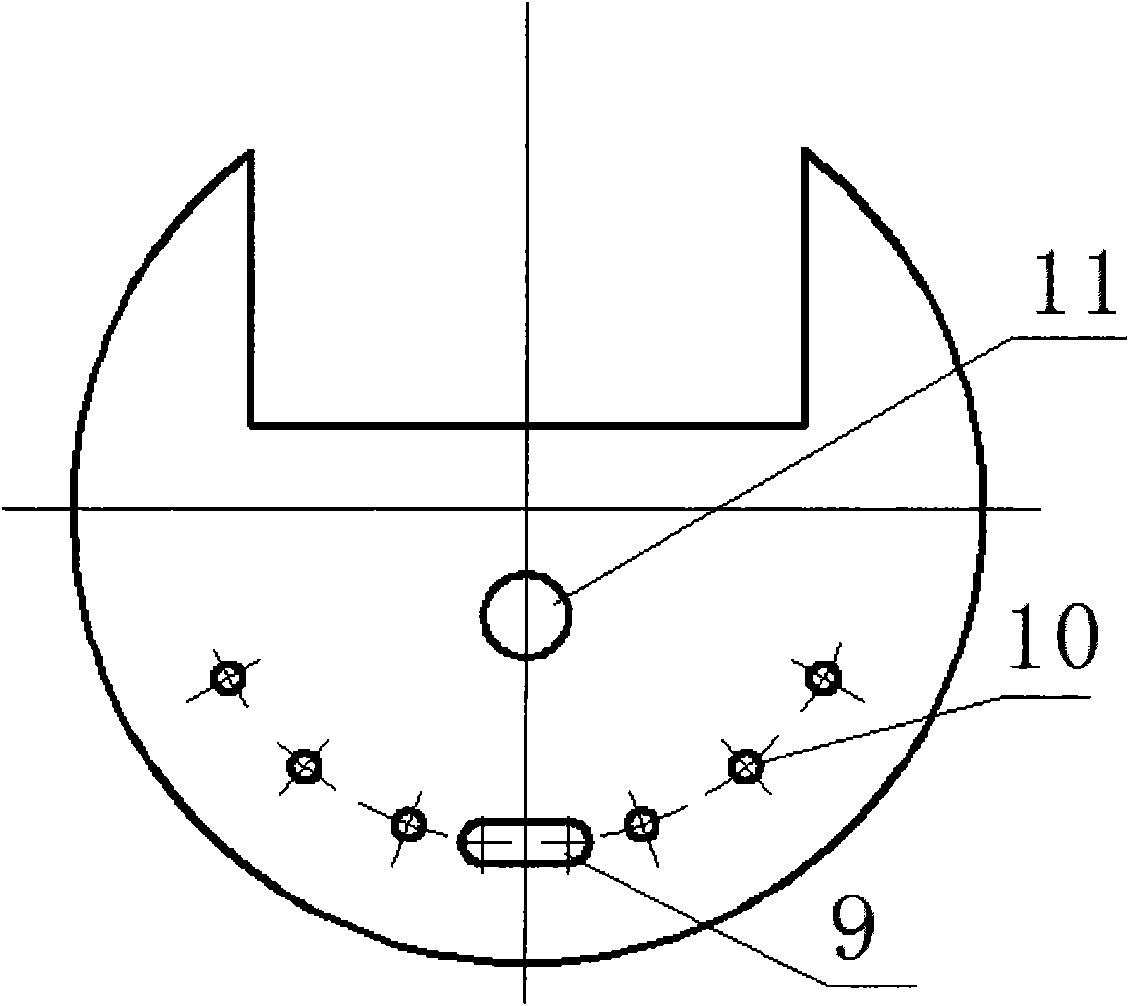

[0033] Embodiment 1: Auto-ignition method for biomass pellet fuel with the highest metal content

[0034] For raw materials such as corn stalks and Korean pine that contain relatively high Si elements and other alkali metal elements, the Si content is basically 25%, and the K element content is 10% to 15%. During combustion, the slagging is the most serious, the ash content is the most, and the ignition is the most difficult. . When igniting, the feed amount of biomass particles is 350g, and the power of the resistance rod is set to high-grade, the power is 400W~450W, the power is the largest, and the heat generated is high. 3.5m / s, to ensure that more heat is generated during ignition. At the same time, the wind speed of the centrifugal fan is the highest, providing higher hot air, which is conducive to the ignition of biomass pellet fuel with the highest metal content.

Embodiment 2

[0035] Embodiment 2: Auto-ignition method for biomass pellet fuel with higher metal content

[0036] For raw materials such as wheat straw and rice straw, which contain generally high Si elements and other alkali metal elements, slagging is serious during combustion, and ignition is difficult. When igniting, the feed amount of biomass particles is 300g, and the power of the resistance rod is set to the mid-range, the power is 350W~400W, the power is higher, and the heat generated is higher. s ~ 3.0m / s, to ensure that more heat is generated during ignition. At the same time, the wind speed of the centrifugal fan is higher, providing higher hot air, which is conducive to the ignition of biomass pellet fuel with higher metal content.

Embodiment 3

[0037] Embodiment 3: be used for the auto-ignition method of the general biomass particle fuel of metal content

[0038] Cotton stalks, larch and other raw materials contain low Si and other alkali metal elements, less slagging and less ash after combustion, and easy ignition. When igniting, the feed amount of biomass particles is 250g, the power of the resistance rod is set to a low level, the power is 300-350W, and the power is the minimum. Heat and hot air can ignite biomass pellet fuel with average metal content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com