Coated cloth for car covering

A technology of coating cloth and covering cloth, applied in the field of coating cloth, can solve the problems of affecting the covering property of PVC covering cloth, prone to cracks, and prone to creases of PVC covering cloth, so as to reduce the absorption of light and heat, reduce the penetration of Over-rate, not easy to breed bacteria effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

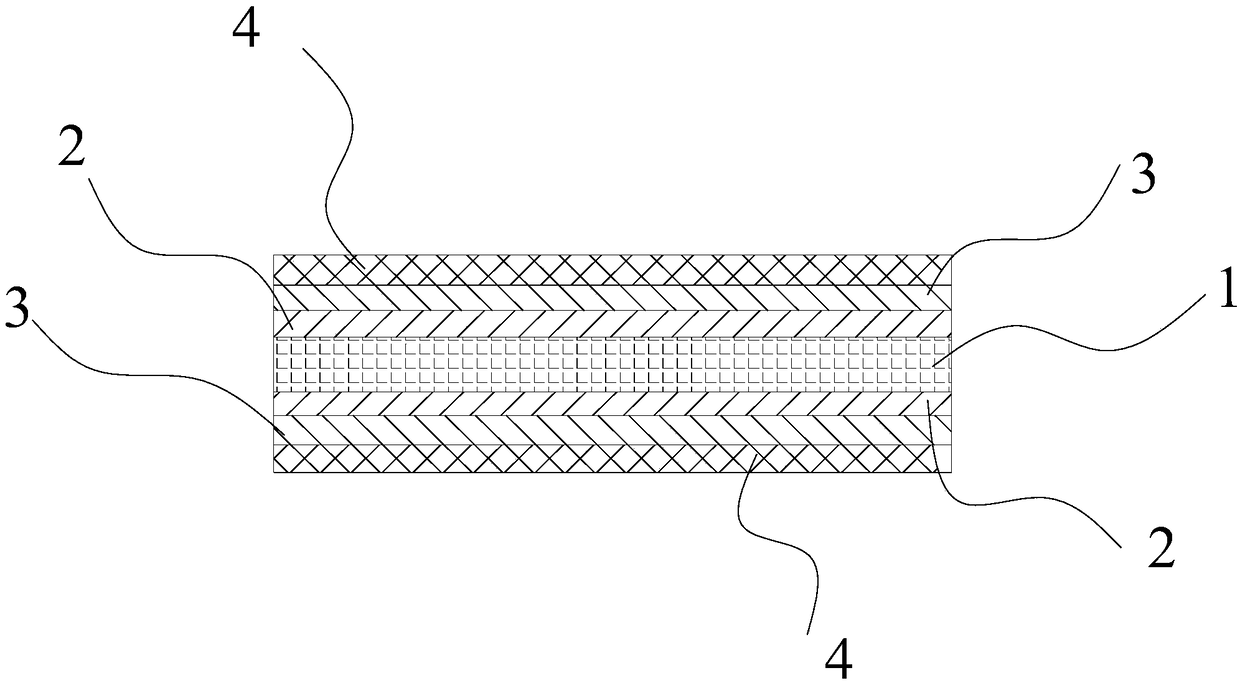

[0037] Such as figure 1 As shown, a kind of coated cloth for car cover cloth of the present embodiment comprises warp knitted fabric 1, the antibacterial coating 2 that is coated on the upper and lower surfaces of warp knitted fabric 1 respectively, and the antibacterial coating 2 that is coated on each antibacterial coating 2 outer surfaces The first coating 3 and the second coating 4 coated on the outer surface of each first coating 3 .

[0038] The paint formula of the antibacterial coating 2 is as follows: 9 parts of bamboo fiber, 1 part of horseradish extract, 3.5 parts of wax gourd kernel extract, 12 parts of polyvinylidene chloride emulsion, and 25 parts of compound emulsion of acrylate copolymer and paraffin.

[0039] The paint formula of the first coating 3 is as follows: PSM31 type polyvinyl chloride paste resin 115 parts, dimethyl phthalate 88 parts, modified ultraviolet absorber 7 parts, polyester silk 1.7 parts, barium zinc 5 parts, LD -100 19 parts of ultrafine ...

Embodiment 2

[0043] Such as figure 1 As shown, a kind of coated cloth for car cover cloth of the present embodiment comprises warp knitted fabric 1, the antibacterial coating 2 that is coated on the upper and lower surfaces of warp knitted fabric 1 respectively, and the antibacterial coating 2 that is coated on each antibacterial coating 2 outer surfaces The first coating 3 and the second coating 4 coated on the outer surface of each first coating 3 .

[0044] The coating formula of the antibacterial coating 2 is as follows: 11 parts of bamboo fiber, 2 parts of horseradish extract, 4.5 parts of wax gourd kernel extract, 14 parts of polyvinylidene chloride emulsion, 28 parts of compound emulsion of acrylate copolymer and paraffin.

[0045] The paint formula of the first coating 3 is as follows: 125 parts of PSM31 polyvinyl chloride paste resin, 98 parts of diisononyl phthalate, 10 parts of modified ultraviolet absorber, 2.2 parts of polyethylene silk, dibasic phosphorous acid 7 parts of le...

Embodiment 3

[0049] Such as figure 1 As shown, a kind of coated cloth for car cover cloth of the present embodiment comprises warp knitted fabric 1, the antibacterial coating 2 that is coated on the upper and lower surfaces of warp knitted fabric 1 respectively, and the antibacterial coating 2 that is coated on each antibacterial coating 2 outer surfaces The first coating 3 and the second coating 4 coated on the outer surface of each first coating 3 .

[0050] The coating formula of the antibacterial coating 2 is as follows: 10 parts of bamboo fiber, 1.5 parts of horseradish extract, 4 parts of wax gourd kernel extract, 13 parts of polyvinylidene chloride emulsion, 26.5 parts of compound emulsion of acrylate copolymer and paraffin.

[0051] The paint formula of the first coating 3 is as follows: 120 parts of PSM31 type polyvinyl chloride paste resin, 93 parts of phthalate diester, 8.5 parts of modified ultraviolet absorber, 2 parts of nylon yarn, 6 parts of calcium zinc, LD-100 20.5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com