Waterproof coating for surface of wooden furniture and preparation method of waterproof coating

A technology for waterproof coatings and wooden furniture, applied in antifouling/underwater coatings, fire-retardant coatings, coatings, etc., can solve the problems of lack of bacteriostatic and flame retardancy, insufficient waterproof performance, and achieve strong molecular movement ability. , The effect of preventing penetration of the coating film and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A wooden furniture surface waterproof coating, made of the following raw materials in parts by weight: 50 parts of modified propylene styrene emulsion, 4 parts of inorganic filler, 0.8 part of flame retardant, 1 part of defoamer, 0.5 part of leveling agent, wetting agent 1 part, 10 parts of deionized water;

[0044] The waterproof coating is made by the following steps:

[0045] The first step is to add deionized water into the container, add wetting agent, half of the defoamer, flame retardant and inorganic filler in sequence under 150r / min uniform stirring state, transfer to the ball mill and mill at 120r / min for 60min;

[0046] The second step, the mixture after ball milling is transferred to the container again, adjust the speed to 700r / min, add the modified propylene styrene emulsion, stir for 10min, add the remaining defoamer and leveling agent, continue stirring for 30-40min, then use 400 Mesh filter.

Embodiment 2

[0048] A wooden furniture surface waterproof coating, made of the following raw materials in parts by weight: 55 parts of modified propylbenzene emulsion, 5 parts of inorganic filler, 0.9 part of flame retardant, 1.5 parts of defoamer, 0.55 part of leveling agent, wetting agent 1.3 parts, 12 parts of deionized water;

[0049] The waterproof coating is made by the following steps:

[0050] The first step is to add deionized water into the container, add wetting agent, half of the defoamer, flame retardant and inorganic filler in turn under the state of 1700r / min uniform stirring, transfer to the ball mill and mill at 120r / min for 60min;

[0051] Step 2: Transfer the ball-milled mixture to the container again, adjust the speed to 750r / min, add the modified propylene styrene emulsion, stir for 15 minutes, add the remaining defoamer and leveling agent, continue stirring for 35 minutes, and use a 400-mesh sieve net filter.

Embodiment 3

[0053] A wooden furniture surface waterproof coating, made of the following raw materials in parts by weight: 60 parts of modified propylene emulsion, 6 parts of inorganic filler, 1 part of flame retardant, 2 parts of defoaming agent, 0.6 part of leveling agent, wetting agent 1.5 parts, 14 parts of deionized water;

[0054] The waterproof coating is made by the following steps:

[0055] The first step is to add deionized water into the container, add wetting agent, half of the defoamer, flame retardant and inorganic filler in sequence under 200r / min uniform stirring state, transfer to the ball mill and mill at 120r / min for 60min;

[0056] The second step, transfer the ball-milled mixture to the container again, adjust the speed to 800r / min, add the modified propylene styrene emulsion, stir for 20min, add the remaining defoamer and leveling agent, continue stirring for 30-40min, then use 400 Mesh filter.

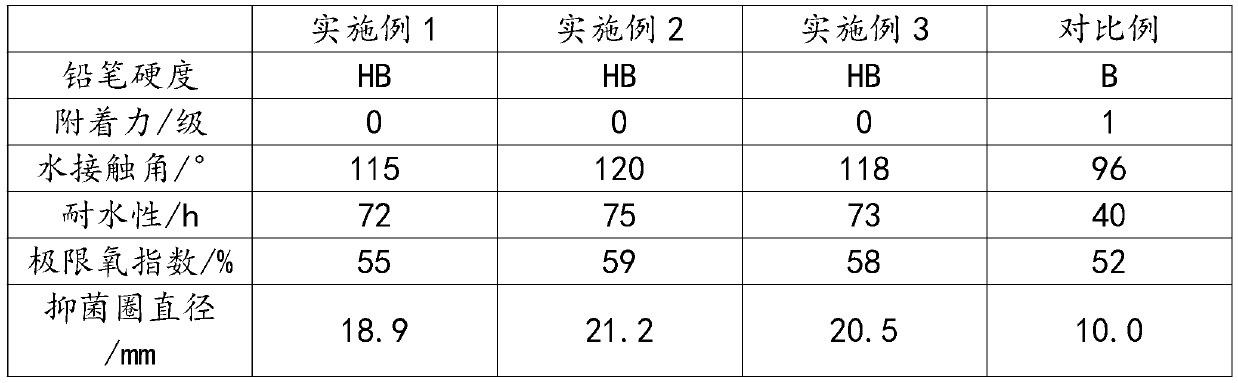

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com