Veneering decorative paper having flame-retardant effect and flame-retardant veneering artificial board using same

A decorative paper and veneer technology, applied in special paper, paper, papermaking and other directions, can solve the problems of high formaldehyde emission, long formaldehyde emission cycle, high free formaldehyde content in decorative paper, achieve good flame retardant effect and prevent fire expansion with spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

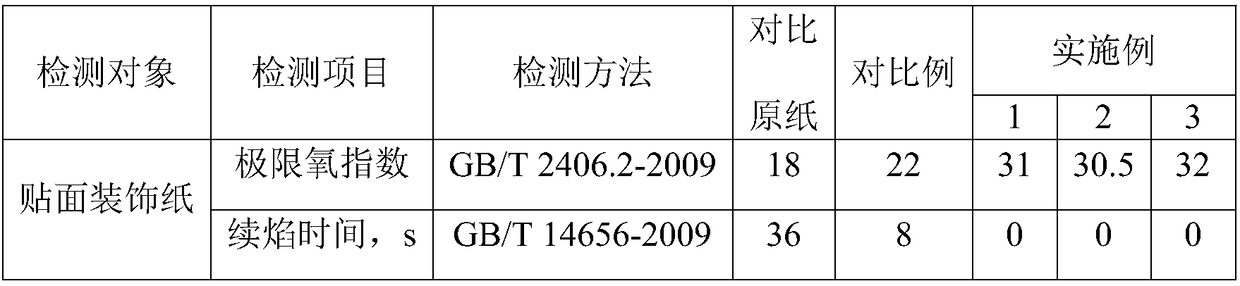

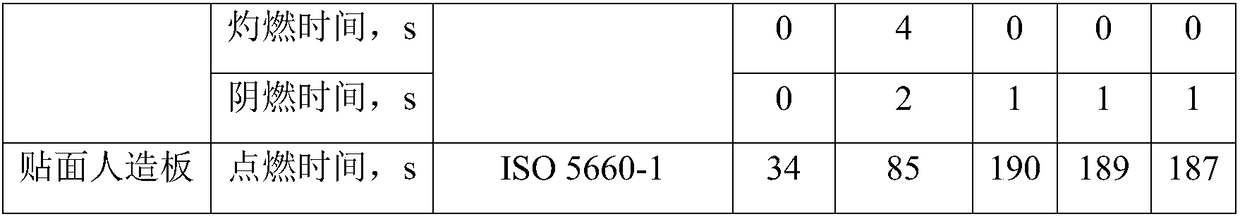

Embodiment 1

[0033] The laminated decorative paper with flame retardant effect of this embodiment is prepared by the following method:

[0034] 1) Preparation of modified starch paste: add phosphate amphoteric starch into water to prepare a starch dispersion with a mass concentration of 1%, heat it in a water bath to 85°C for 30 minutes to fully gelatinize, and cool to obtain a modified starch paste;

[0035] According to the mass ratio of coniferous wood pulp to hardwood pulp at a ratio of 3:7, take the coniferous wood pulp and hardwood pulp to be beaten separately, mix and decompose, add titanium dioxide dispersion, retention aid, wet strength agent and modified starch The paste is evenly mixed so that the amount of titanium dioxide added is 20% of the absolute dry pulp mass, the amount of retention aid is 0.8% of the absolute dry pulp mass, the amount of wet strength agent is 1.2% of the absolute dry pulp mass, and the amount of modified starch is 1.0% of the mass of the absolute dry pulp, a...

Embodiment 2

[0041] The laminated decorative paper with flame retardant effect of this embodiment is prepared by the following method:

[0042] 1) Preparation of modified starch paste: add phosphate amphoteric starch to water to prepare a starch dispersion with a mass concentration of 1.2%, heat it in a water bath to 90°C for 15 minutes to fully gelatinize, and cool to obtain a modified starch paste;

[0043] According to the mass ratio of coniferous wood pulp and hardwood pulp of 4:6, take coniferous wood pulp and hardwood pulp to be beaten separately, mix and decompose, add titanium dioxide dispersion, retention aid, wet strength agent and modified starch The paste is evenly mixed so that the amount of titanium dioxide added is 22% of the absolute dry pulp mass, the amount of retention aid is 1.0% of the absolute dry pulp mass, the amount of wet strength agent is 0.8% of the absolute dry pulp mass, and the amount of modified starch is 1.2% of the mass of the absolute dry pulp, adjusted to neu...

Embodiment 3

[0049] The laminated decorative paper with flame retardant effect of this embodiment is prepared by the following method:

[0050] 1) Preparation of modified starch paste: add phosphate amphoteric starch to water to prepare a starch dispersion with a mass concentration of 1.5%, heat it in a water bath to 90°C for 25 minutes to fully gelatinize, and cool to obtain a modified starch paste;

[0051] According to the mass ratio of coniferous wood pulp and hardwood pulp as 3.5:6.5, take the coniferous wood pulp and hardwood pulp to be beaten separately, mix and decompose, add titanium dioxide dispersion, retention aid, wet strength agent and modified starch The paste is evenly mixed so that the amount of titanium dioxide added is 25% of the absolute dry pulp mass, the amount of retention aid is 1.2% of the absolute dry pulp mass, the amount of wet strength agent is 1.0% of the absolute dry pulp mass, and the amount of modified starch is 1.5% of the mass of the absolute dry pulp, adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com