Efficient counter-distributary self-preheating low-NOx combustion device

A technology of combustion device and reverse cross flow, which is applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of reducing flame temperature and rising, so as to increase heat exchange area, increase heat exchange area, facilitate automatic ignition and online The effect of flame monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

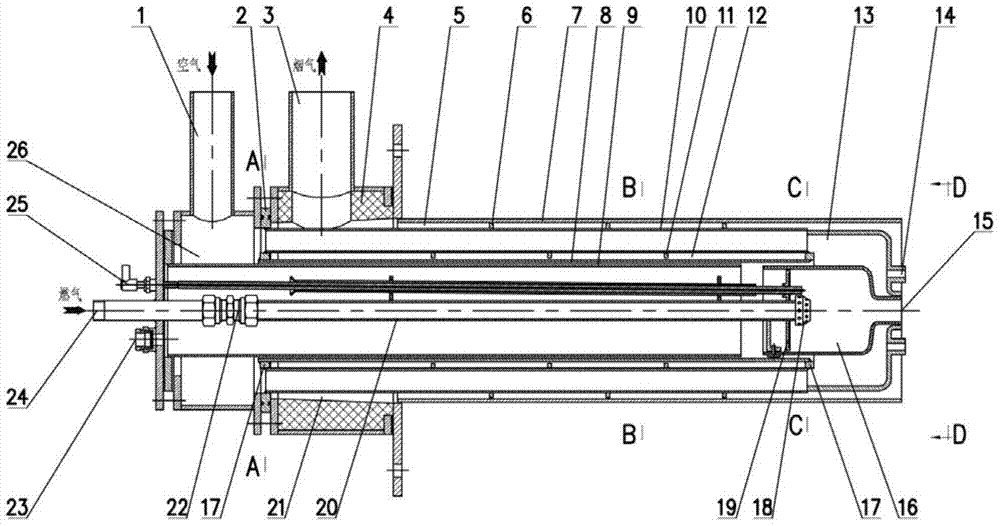

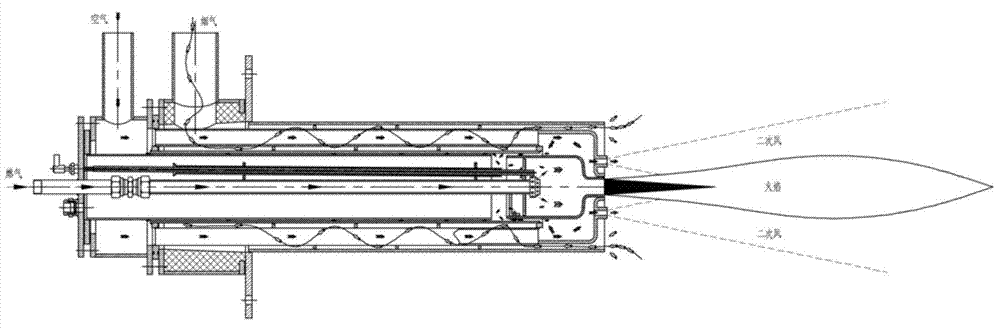

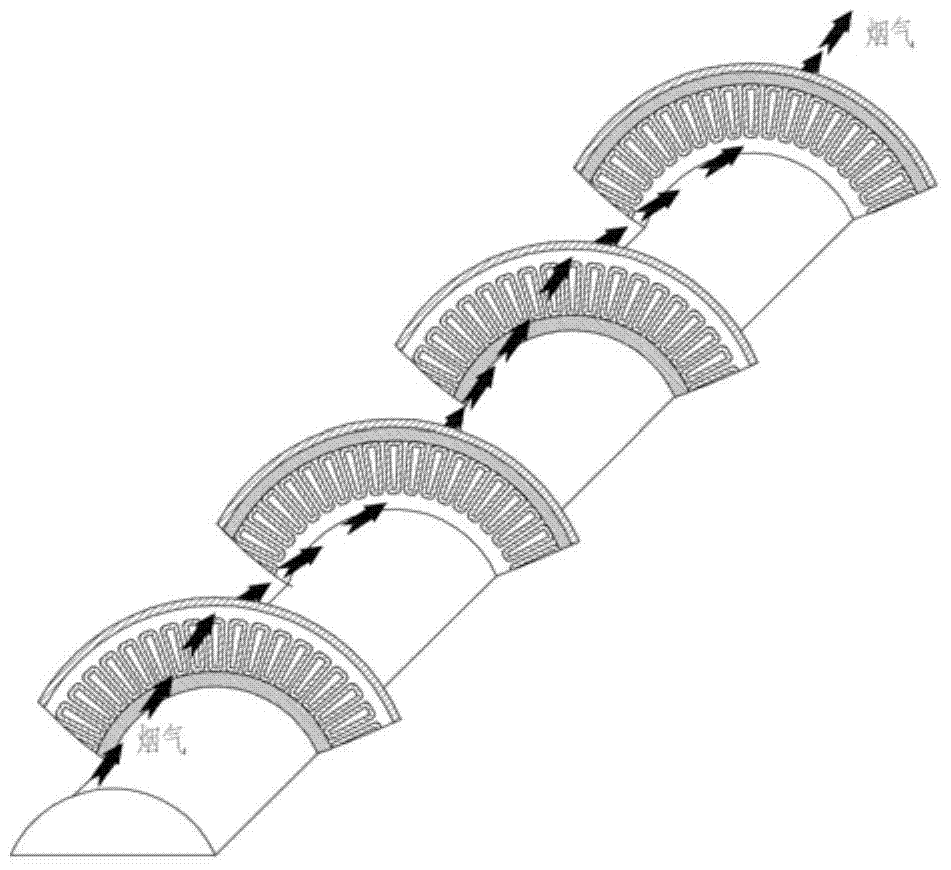

[0033] see Figure 1 to Figure 7 , the present invention includes a gas core tube 20 and a combustion chamber 16 arranged at the front end of the gas core tube 20, the gas nozzle 18 of the gas core tube 20 is located in the combustion chamber 16, and the outside of the combustion chamber 16 is also equipped with an air outlet chamber 13, the air A number of secondary air holes 14 are provided on the front end surface of the outlet air chamber 13, and a combustion chamber spout 15 is provided on the front end surface of the combustion chamber 16; Figure 7 As shown, the secondary air holes 14 are equidistantly arranged around the nozzle 15 of the combustion chamber, and the center distance between the secondary air holes 14 and the nozzle 15 of the combustion chamber is 1.5 to 2 times the diameter of the nozzle of the combustion chamber. Such as Figure 6 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com