Composite halogen-free flame-retardant smoke suppression agent of PVC wood-plastic composite material and preparation method and application of agent

A wood-plastic composite material and composite halogen-free technology, which is applied in the field of flame retardant and smoke suppressant, can solve the problems of poor flame retardant and smoke suppression effects, harmful environment and people's health, and large addition of flame retardant and smoke suppressant, etc. Low cost, little impact on machining performance, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

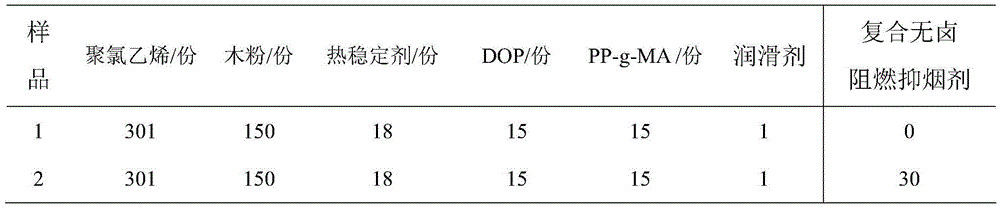

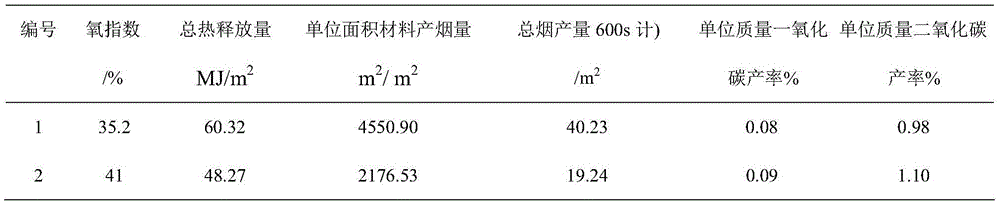

Examples

specific Embodiment approach 1

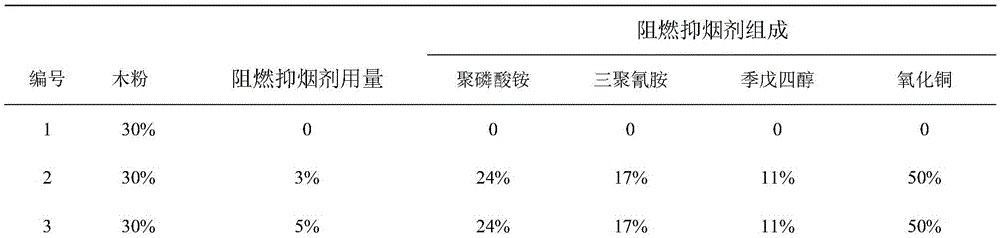

[0036] Specific embodiment 1: In this embodiment, a composite halogen-free flame-retardant smoke suppressant of PVC wood-plastic composite material is composed of polyphosphate amine, melamine, pentaerythritol and copper oxide, according to the mass ratio Composition of ammonium polyphosphate: melamine: pentaerythritol: copper oxide = (0.4-4): (0.3-3): (0.3-3): 1; the degree of polymerization of the ammonium polyphosphate n>1500.

[0037] This embodiment has the following beneficial effects:

[0038] 1. The composite halogen-free flame retardant and smoke suppressant of this embodiment performs flame retardant and smoke suppression treatment on wood fiber and polyvinyl chloride, the main components of the wood-plastic composite material, and the wood fiber material doubles as an auxiliary charcoal forming agent in the flame retardant system. The flame retardant and smoke suppression effect has obvious advantages, and the addition amount is small and the cost is low.

[0039] ...

specific Embodiment approach 2

[0047] Embodiment 2: This embodiment differs from Embodiment 1 in that: the degree of polymerization of the ammonium polyphosphate n>1500. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: This embodiment is a method for preparing a composite halogen-free flame retardant and smoke suppressant of PVC wood-plastic composite material, the method is carried out according to the following steps:

[0049] 1. According to the mass ratio: polyphosphate amine: melamine: pentaerythritol: copper oxide = (0.4 ~ 4): (0.3 ~ 3): (0.3 ~ 3): 1 Weigh polyphosphate amine, melamine, pentaerythritol and copper oxide as Raw materials, put the weighed amine polyphosphate, melamine and pentaerythritol in a high-speed mixer, and stir at a speed of 2000r / min to 2500r / min for 10min to 15min to complete the preparation of the intumescent flame retardant;

[0050] 2. Add the copper oxide weighed in step 1 as a flame retardant synergist to the intumescent flame retardant prepared in step 1, and stir in a high-speed mixer at a speed of 2000r / min to 2500r / min for 10min to 15min , that is to complete the preparation of the PVC wood-plastic composite compound ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com