Mineral slag micropowder modified polypropylene composite and preparation method thereof

A technology of slag micropowder and composite materials, which is applied in the field of composite materials, and can solve the effects of mechanical properties, optical properties, thermal properties and flame retardancy of polymer processed products, and the compatibility and dispersion of activated calcium carbonate with polyethylene and polypropylene Failure to meet the requirements and other problems, to achieve the effect of prolonging the ignition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

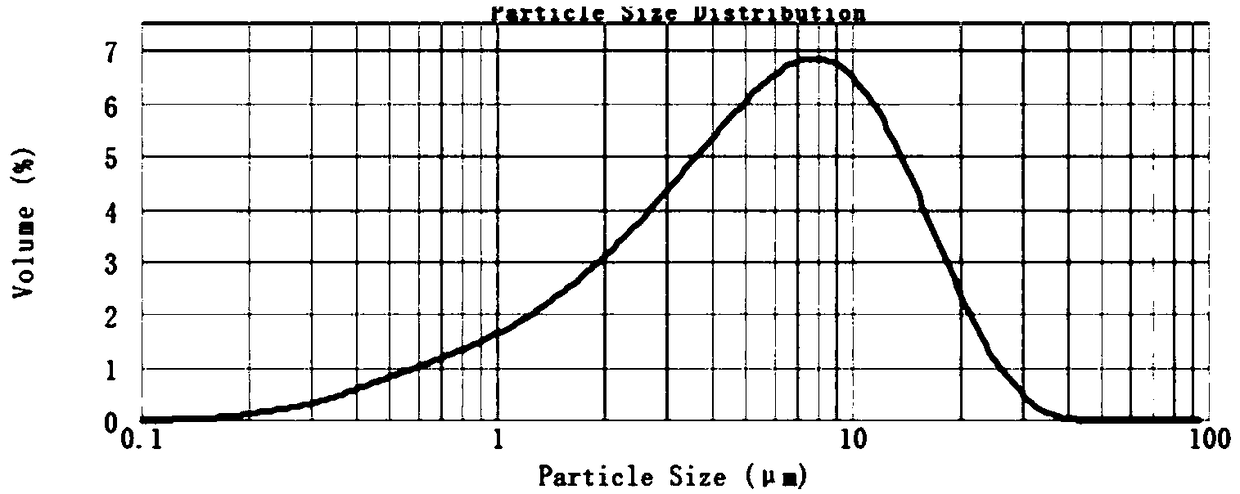

[0038] The preparation method of the slag micropowder modified polypropylene composite material is as follows: Weigh the raw materials according to the following ratio, silane coupling agent 1%, slag micropowder 10%, polypropylene 89%; wherein, the slag micropowder has a bulk density of 950kg / m 3 , with an average particle size of 1 μm, melted and blended at a speed of 5 r / min at a high temperature of 210 ° C for 5 min to obtain.

Embodiment 2

[0040] The preparation method of the slag micropowder modified polypropylene composite material is as follows: Weigh the raw materials according to the following ratio, 10% of silane coupling agent, 30% of slag micropowder, and 60% of polypropylene; wherein, the bulk density of slag micropowder is 970kg / m 3 , with an average particle size of 10 μm, melted and blended at a speed of 10 r / min at a high temperature of 230 ° C for 15 min to obtain.

Embodiment 3-7

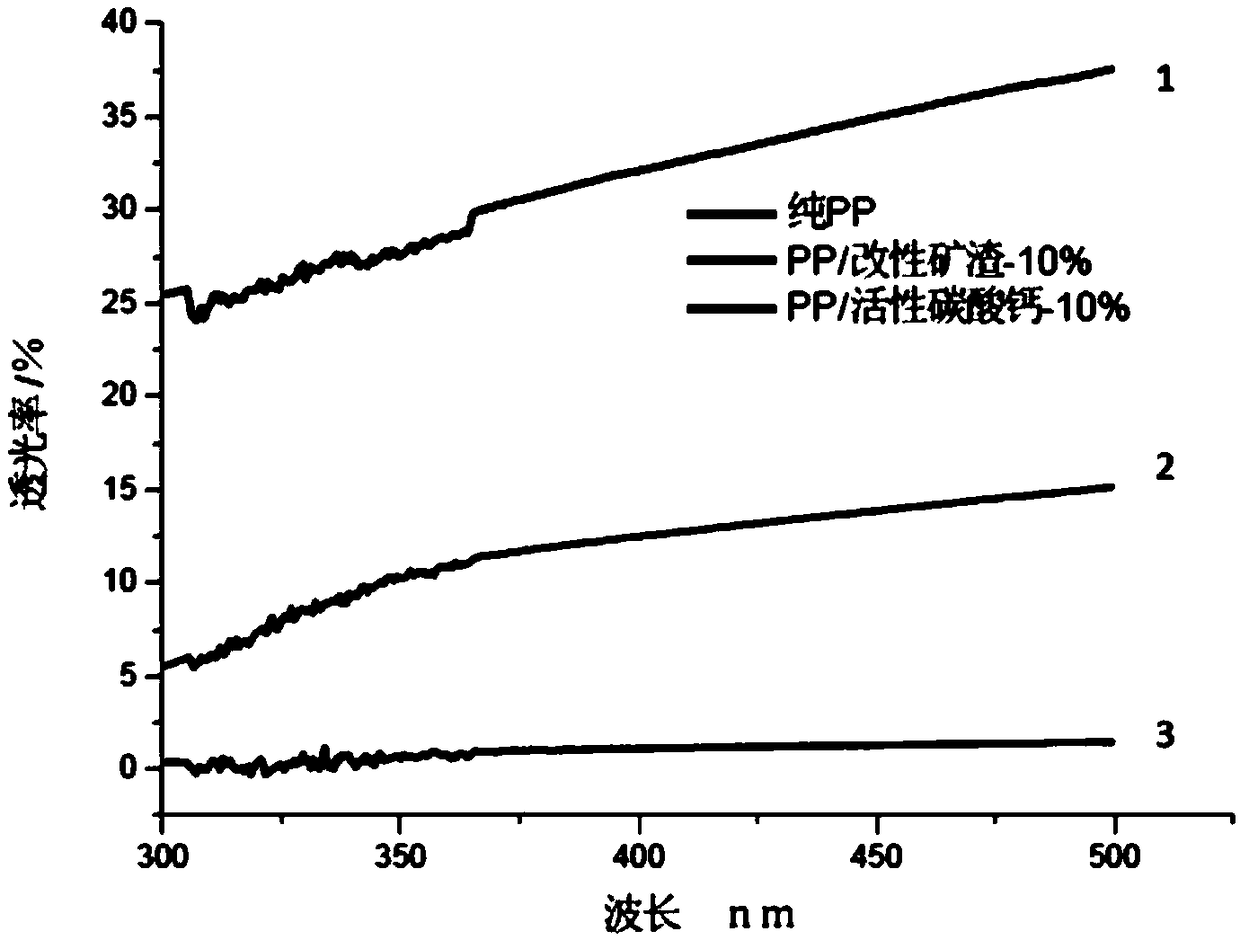

[0057] Prepare slag micropowder modified plastic composite material, wherein, the content of slag micropowder in embodiment 3-7 is successively 2%, 5%, 10%, 20% and 30%, and the mass percent of silane coupling agent, polypropylene is 100%; Then the composite material prepared by embodiment 3-7 and pure polypropylene are carried out tensile property and thermal property test, and the results are as table 4 and Figure 4 shown.

[0058] Table 4: Tensile test data

[0059]

[0060]It can be seen from Table 4 that the addition of slag fine powder reduces the elongation at break and the maximum tensile force of the plastic, which is mainly due to the fact that the addition of slag destroys the continuity of the polymer matrix, and the addition of slag fine powder has an effect on polypropylene The elongation at break and the maximum tensile force are well maintained, so that the tensile yield stress and fracture stress of polypropylene both increase first and then decrease. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com