Coated fabric for liquid bag and preparation method thereof

A technology of coated cloth and liquid bag, applied in the field of coated cloth, can solve the problems of acid and alkali resistance, weak corrosion resistance, weak acid and alkali corrosion resistance, short service life, etc., and achieve strong acid and alkali corrosion resistance, Good flame retardant effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

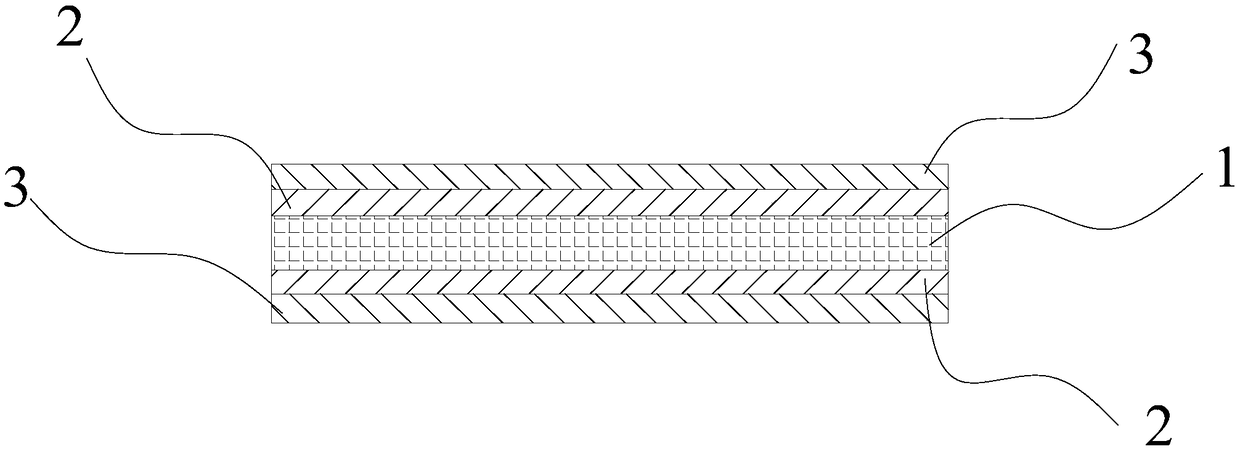

[0033] Such as figure 1 As shown, a kind of coated cloth for liquid bags of the present embodiment comprises a base cloth 1, a first coating 2 and a second coating 3; wherein, the base cloth 1 is made of sea-island fibers and polyester fibers according to the material ratio 1: 2 blended, the two ends of the base cloth 1 are respectively provided with a layer of first coating 2, and the ends of each first coating 2 are respectively provided with a second coating 3.

[0034] The paint formula of the first coating 2 is as follows: 90 parts of PSM31 type polyvinyl chloride paste resin, 70 parts of dimethyl phthalate, 80 parts of paraffin wax, 60 parts of epoxy soybean oil, 2 parts of barium zinc, LD-100 super 30 parts of fine calcium carbonate, 10 parts of nano calcium carbonate, 5 parts of epoxy resin, 2 parts of phenol, 80 parts of halogen-free phosphorus flame retardant, 4 parts of ammonium molybdate;

[0035] The paint formula of the second coating 3 is as follows: 45 parts o...

Embodiment 2

[0037] Such as figure 1 As shown, a kind of coated cloth for liquid bags of the present embodiment comprises a base cloth 1, a first coating 2 and a second coating 3; wherein, the base cloth 1 is made of sea-island fibers and polyester fibers according to the material ratio 1: 3 blended, the two ends of the base cloth 1 are respectively provided with the first coating 2, and the ends of each first coating 2 are respectively provided with the second coating 3.

[0038] The paint formula of the first coating 2 is as follows: 110 parts of PSM31 type polyvinyl chloride paste resin, 80 parts of diisobutyl phthalate, 90 parts of paraffin wax, 70 parts of epoxy soybean oil, 4 parts of dibasic lead phosphite , 40 parts of LD-100 superfine calcium carbonate, 20 parts of nano calcium carbonate, 9 parts of polyurethane, 6 parts of pentachlorophenol, 100 parts of halogen-free phosphorus flame retardant, 15 parts of ammonium molybdate;

[0039] The paint formula of the second coating 3 is...

Embodiment 3

[0041] Such as figure 1 As shown, a kind of coated cloth for liquid bags of the present embodiment comprises a base cloth 1, a first coating 2 and a second coating 3; wherein, the base cloth 1 is made of sea-island fibers and polyester fibers according to the material ratio 1: 2.5 blended, the two ends of the base fabric 1 are respectively provided with the first coating 2, and the ends of each first coating 2 are respectively provided with the second coating 3.

[0042] The coating formula of the first coating 2 is as follows: 100 parts of PSM31 type polyvinyl chloride paste resin, 75 parts of diisononyl phthalate, 85 parts of paraffin wax, 65 parts of epoxy soybean oil, 3 parts of calcium zinc, LD-100 35 parts of superfine calcium carbonate, 15 parts of nano calcium carbonate, 7 parts of polystyrene, 4 parts of tributyltin, 90 parts of halogen-free phosphorus flame retardant, 9 parts of ammonium molybdate;

[0043] The paint formula of the second coating 3 is as follows: 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com