A kind of flame-retardant vegetable oil-based water-based polyurethane coating and preparation method thereof

A water-based polyurethane and polyurethane coating technology, applied in polyurea/polyurethane coatings, fire-retardant coatings, epoxy resin coatings, etc., can solve the problem of lack of flame retardant properties, improve various properties, reduce costs, and high reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

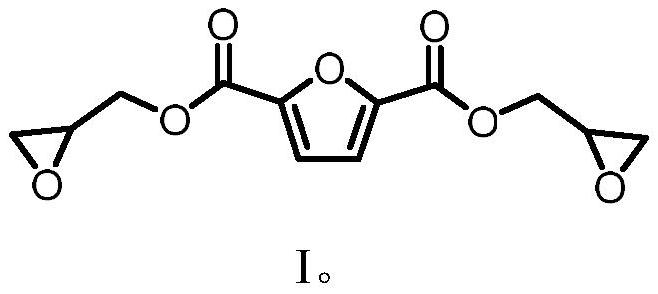

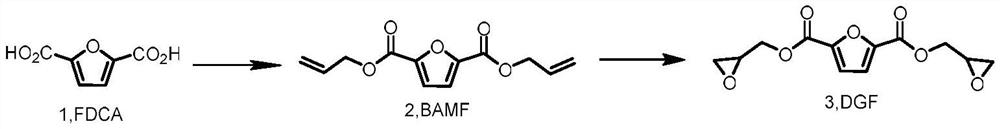

[0055] The preparation method of the compound shown in formula I comprises the steps:

[0056] (1) FDCA (21.2g, 1.0eq) was dissolved in N,N-dimethylformamide (DMF, 80mL) and added to a round bottom flask with vigorous stirring, then allyl bromide (49.2g, 3.0eq ), K 2 CO 3(56.2 g, 3.0 equivalents) was added to the mixture, and the mixture was heated to 50° C. for 2 days. After the reaction, the mixture was rotary evaporated to remove unreacted allyl bromide, then the mixture was washed repeatedly with water and extracted with dichloromethane, the organic layer was collected, and dried with anhydrous sodium sulfate, separated by silica gel column to obtain yellow BAMF solid (27.2g , 85%).

[0057] (2) BAMF (11.8g, 1.0eq) and m-CPBA (21.5g, 2.5eq) were added to dichloromethane (80mL) and reacted at 40°C for 3 days, and the suspension obtained by filtration was extracted with dichloromethane , the collected organic phase was washed with aqueous sodium bisulfite, and then washe...

Embodiment 1

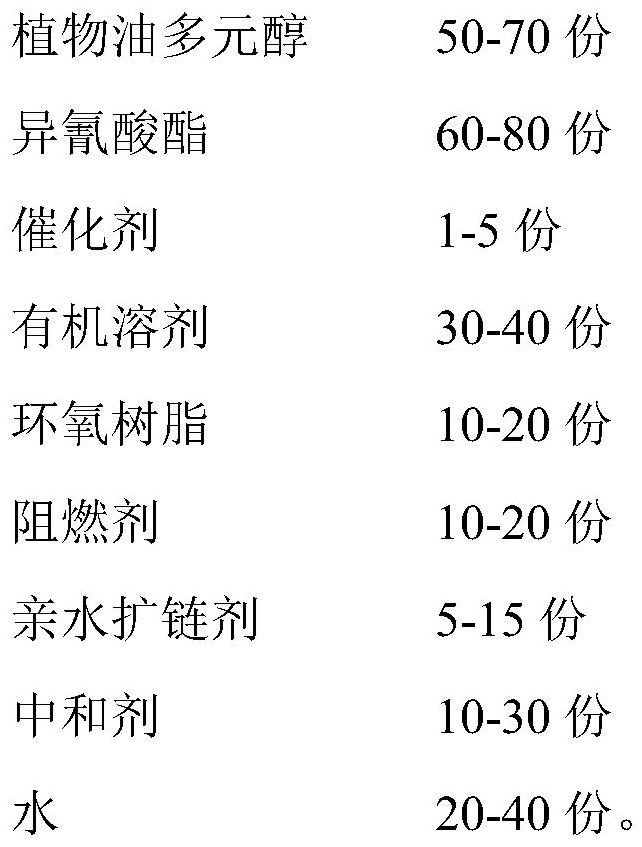

[0059] Mix 65 parts of vegetable oil polyols (hydroxyl value 170mgKOH / g, derived from cottonseed oil) with 60 parts of isophorone diisocyanate (IPDI) in 30 parts of acetone and add 2 parts of dibutyltin dilaurate, at 50 The reaction was carried out at ℃ for 2 hours to obtain a prepolymer mixed solution. Add 15 parts of epoxy resin I, 18 parts of flame retardant casein and 9 parts of hydrophilic chain extender dihydroxy half ester to the prepolymer mixture, and react at 50°C for 3 hours to obtain a polymer mixture. Cool the polymer mixed solution to 30°C, add 25 parts of neutralizing agent triethylamine to neutralize the polymer mixed solution, add 30 parts of deionized water for high-speed shear emulsification to form polyurethane emulsion. The acetone was distilled off the polyurethane emulsion under reduced pressure to obtain a flame-retardant vegetable oil-based waterborne polyurethane coating.

Embodiment 2

[0061] Mix 50 parts of vegetable oil polyol (hydroxyl value 160 mgKOH / g, derived from sesame oil) and 60 parts of toluene diisocyanate (TDI) in 35 parts of toluene, add 1 part of dibutyltin dilaurate, and react at 50 ° C for 2 hours to obtain the prepolymer mixture. Add 10 parts of epoxy resin I, 18 parts of flame retardant bis(4-hydroxyphenyl) phenylphosphine oxide and 5 parts of hydrophilic chain extender dimethylol propionic acid to the prepolymer mixture, at 50 °C React at high temperature for 3 hours to obtain a polymer mixture. Cool the polymer mixed solution to 30°C, add 20 parts of neutralizing agent triethanolamine to neutralize the polymer mixed solution, and add 20 parts of deionized water for high-speed shear emulsification to form a polyurethane emulsion. The toluene was distilled off the polyurethane emulsion under reduced pressure to obtain a flame-retardant vegetable oil-based waterborne polyurethane coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com