A kind of modified expandable graphite, flame retardant and its preparation method and application in polyurethane foam

An expanded graphite and flame retardant technology, applied in the field of flame retardants, can solve the problems of poor flame retardant performance and uneven dispersion of graphite particles, and achieve good flame retardant performance, reduced peak heat release rate, and lasting flame retardant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of modified expandable graphite, characterized in that the preparation process steps of the modified expandable graphite are as follows: (1) Shaping process: put the expandable graphite into a mechanical impact mill for shaping, and then vibrate Sieve classification, return to re-production if it is less than 80 mesh, and enter the next modification section if it is 80-150 mesh, and it will be processed separately if it is larger than 150 mesh; (2) Modification process: the 80-150 mesh expandable graphite obtained in step (1) Put it into the mixer, stir at a low speed, the speed is 50-85r / min, add the polymer surface modifier, after stirring for 10-15 minutes, increase the speed to 150-200r / min, stir for 20-30 minutes, then 80 The modified expandable graphite can be obtained by sieving. The step (2) modified expandable graphite is spherical or ellipsoidal particles, and the wetting angle is 78-80°, and the volume resistivity is 0.10-0.30Ω. cm, the t...

Embodiment 1

[0033] S1: Put the expandable graphite into a mechanical impact mill for shaping, then classify with a vibrating sieve, and screen out 100 parts of the shaped graphite under the 80 mesh sieve and on the 120 mesh sieve;

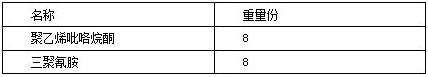

[0034] S2: Under low-speed stirring (50-85r / min), add 100 parts of 80-120 mesh expandable graphite obtained in step (1) and the following materials in sequence. After stirring for 10-15 minutes, increase the speed to 150-200r / min, stir for 20-30 minutes, and then sieve through 80 mesh;

[0035]

[0036] After testing, the obtained modified expandable graphite is ellipsoidal particles with a wetting angle of 78°, a volume resistivity of 0.19Ω cm, a thermal conductivity of 12.7 W / (m K), and a bulk density of 0.21 g cm -3 . Particle size distribution: D10≤25um (500 mesh); D50≤125um (120 mesh); D90≤150um (100 mesh); D max ≤170um (80 mesh).

[0037] S3: Add 4 parts of organic bentonite to the above-mentioned modified expandable graphite, and mix uniformly in ...

Embodiment 2

[0040] S1: Put the expandable graphite into a mechanical impact mill for shaping, then classify with a vibrating sieve, and screen out 100 parts of the shaped graphite under the 80 mesh sieve and on the 120 mesh sieve;

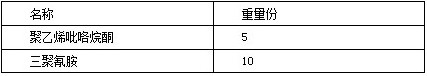

[0041] S2: Under low-speed stirring (50-85r / min), add 100 parts of 80-120 mesh expandable graphite obtained in step (1) and the following materials in sequence. After stirring for 10-15 minutes, increase the speed to 150-200r / min, stir for 20-30 minutes, and then sieve through 80 mesh;

[0042]

[0043] After testing, the obtained modified expandable graphite is ellipsoidal particles with a wetting angle of 78°, a volume resistivity of 0.22Ω cm, a thermal conductivity of 13.0 W / (m K), and a bulk density of 0.16 g cm -3 . Particle size distribution: D10≤35um (400 mesh); D50≤125um (120 mesh); D90≤170um (80 mesh); D max ≤300um (50 mesh).

[0044] S3: Add 2 parts of nano-calcium carbonate to the above-mentioned modified expandable graphite, and mix uniformly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com