Flame-retardant type polyurethane rigid foam and preparation method thereof

A rigid foam, polyurethane technology, applied in the field of material processing, can solve the problems of inability to form a stable interface phase, lack of active groups, poor wettability, etc., to reduce the heat release rate and smoke production, and promote the formation of cross-linked networks. , The effect of good flame retardant and smoke suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

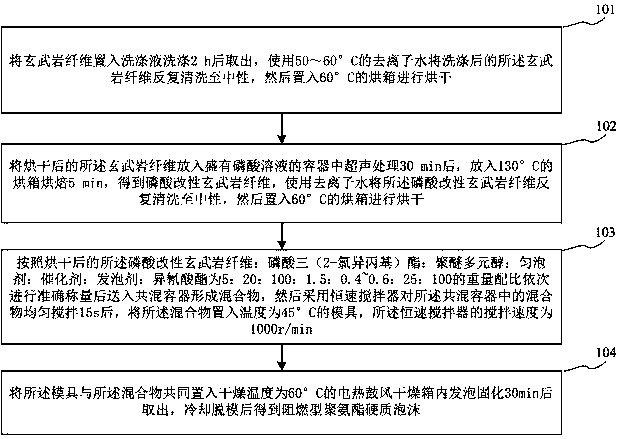

[0026] figure 1 It is a method flow chart of a preparation method of a flame-retardant polyurethane rigid foam shown according to an exemplary embodiment, such as figure 1 Shown, the preparation method of described flame-retardant type polyurethane rigid foam comprises:

[0027] Step 101, put the basalt fiber into the washing liquid and wash it for 2 hours, then take it out, use 50-60°C deionized water to repeatedly wash the washed basalt fiber to neutrality, and then place it in an oven at 60°C for drying Dry.

[0028] Among them, the washing liquid is to remove impurities such as grease and dust on the surface of the basalt fiber.

[0029] Step 102, put the dried basalt fiber into a container filled with phosphoric acid solution and ultrasonically treat it for 30 minutes, then put it into a 130°C oven and bake for 5 minutes to obtain phosphoric acid modified basalt fiber, and use deionized water to dissolve the The phosphoric acid-modified basalt fiber was repeatedly wash...

Embodiment 1

[0043] In step 201, put the basalt fiber into the washing solution for washing for 2 hours, then take it out, use 50°C deionized water to repeatedly wash the washed basalt fiber until neutral, and then place it in an oven at 60°C for drying.

[0044] Wherein, the washing solution is a mixed solution formed by blending a sodium dodecylsulfonate solution with a mass concentration of 1.0 g / L and a sodium carbonate solution with a mass concentration of 2.0 g / L; the basalt fiber and the The bath ratio of the washing liquid is 1:50, and the washing temperature is 95°C.

[0045] Step 202, put the dried basalt fiber into a container filled with phosphoric acid solution for ultrasonic treatment for 30 minutes, then put it into an oven at 130°C and bake for 5 minutes to obtain phosphoric acid modified basalt fiber, and use deionized water to dissolve the The phosphoric acid-modified basalt fiber was repeatedly washed to neutrality, and then placed in an oven at 60°C for drying.

[0046...

Embodiment 2

[0053] Step 301, according to the weight ratio of polyether polyol:foam stabilizer:amine catalyst:tin catalyst:foaming agent:isocyanate 100:1.5:0.2~0.3:0.2~0.3:25:100, carry out accurate weighing in sequence Feed into the blending container after measuring to form a mixture, then use a constant speed stirrer to uniformly stir the mixture in the blending container for 15s, then put the mixture into a mold with a temperature of 45°C, and the constant speed stirrer The stirring speed is 1000r / min.

[0054] Step 302, put the mold and the mixture together into an electric blast drying oven with a drying temperature of 60° C., foam and solidify for 30 minutes, take it out, and cool and demould to obtain a flame-retardant polyurethane rigid foam.

[0055] It should be noted that, in one possible case, the amine catalyst is triethylenediamine, the tin catalyst is stannous octoate, the polyether polyol is 4110, and the foam The agent is silicone oil, the blowing agent is HCFC-141b, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com