Method for preparing carbon nanometer paper flame resistant polymer matrix composite material

A technology of flame-retardant polymer and carbon nano-paper, which is applied in the direction of chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of fast burning, flammability, and environmental pollution, and achieve good resistance Combustibility characteristics, the effect of improving the flame retardant and fireproof characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

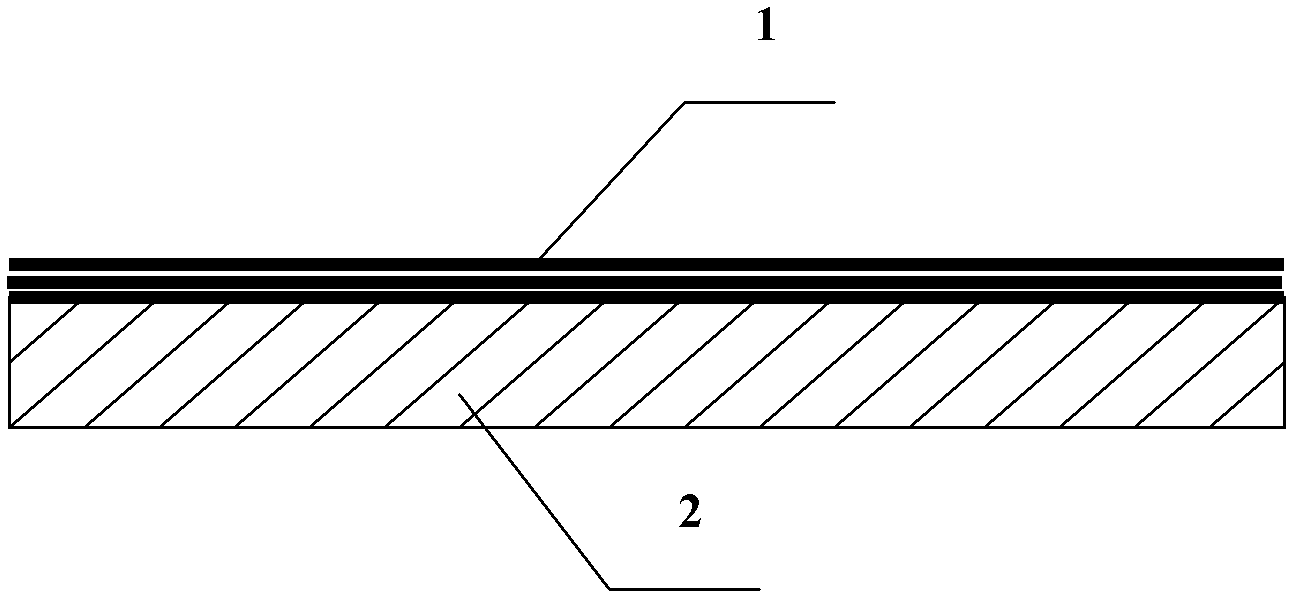

[0034] Carbon nanopaper is a self-supporting felt structure formed by intertwined carbon nanotubes. This continuous defect-free network structure can form a protective barrier to reduce the rate of composite material loss and material combustion. Since the size of carbon nanotubes is nanoscale, the structure of carbon nanopaper formed by them and the gaps between them is very dense. When a fire occurs, this dense network structure and gaps can prevent the penetration of gases and substances, so when carbon nanotubes Paper has very good flame retardant properties when used as the outer skin of polymer-based composites.

[0035] Since there are only carbon nanotubes inside the carbon nano paper, when a fire occurs, the carbon nanotube carbon deposition protective layer is formed slower than the speed of flame expansion. In order to improve the performance of carbon nano paper flame retardant composite materials, this paper Invented to add a variety of flame retardant materials (...

Embodiment 2

[0050] The carbon nanotubes of this embodiment select commercially available single-walled carbon nanotubes with a diameter of 6-10nm and a length of 10-25 μm; the flame retardant is POSS monomer; Two kinds of sodium dialkylbenzene sulfonate are mixed; the realization steps are:

[0051] (1) The mass ratio of carbon nanotubes to flame retardant is 10:2, wherein the carbon nanotubes have a diameter of 6-10 nm and a length of 10-25 μm;

[0052] (2) get carbon nanotube flame retardant mixture and anionic surface dispersant to mix by 1: 20 mass ratio;

[0053] (3) Put the carbon nanotube / flame retardant mixture and the surface dispersant into the mortar and grind for 1-60min, pour it into a beaker, add plasma water until the concentration of the carbon nanotube / flame retardant mixture is 0.01wt%, and the surface dispersant The concentration is 0.1wt%;

[0054] (4) Pour the mixed solution into a magnetic stirrer, control the temperature at 20-60°C, disperse for 15-60min, and defo...

Embodiment 3

[0063] The carbon nanotubes of this embodiment select commercially available functionalized carbon nanotubes (hydroxylated or carboxylated carbon nanotubes, with a diameter of 6-10 nm and a length of 10-25 μm; the flame retardant is ammonium polyphosphate, sodium-based nanomono Soil mixing; the anionic surfactant is sodium dodecylsulfonate;

[0064] Implementation steps:

[0065] (1) The mass ratio of carbon nanotubes to flame retardant is 10:3, the diameter of functionalized carbon nanotubes is 11-20nm, and the length is 20-35μm;

[0066] (2) Take the carbon nanotube / flame retardant mixture and mix it with anionic surface dispersant in a ratio of 1:15;

[0067] (3) Put the carbon nanotube / flame retardant mixture and the surface dispersant into a mortar and grind for 1-60min, pour into a beaker, add plasma water until the concentration of the carbon nanotube / flame retardant mixture is 1.0wt%, and the surface dispersant The concentration is 0.01wt%;

[0068] (4) Pour the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com