Conductive additive and application, conductive composite material and preparation method and application thereof

A technology of conductive composite materials and conductive additives, applied in the field of conductive additives and applications, conductive composite materials and their preparation, can solve problems such as damage to performance and application range, and decline in mechanical properties of conductive polymer composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

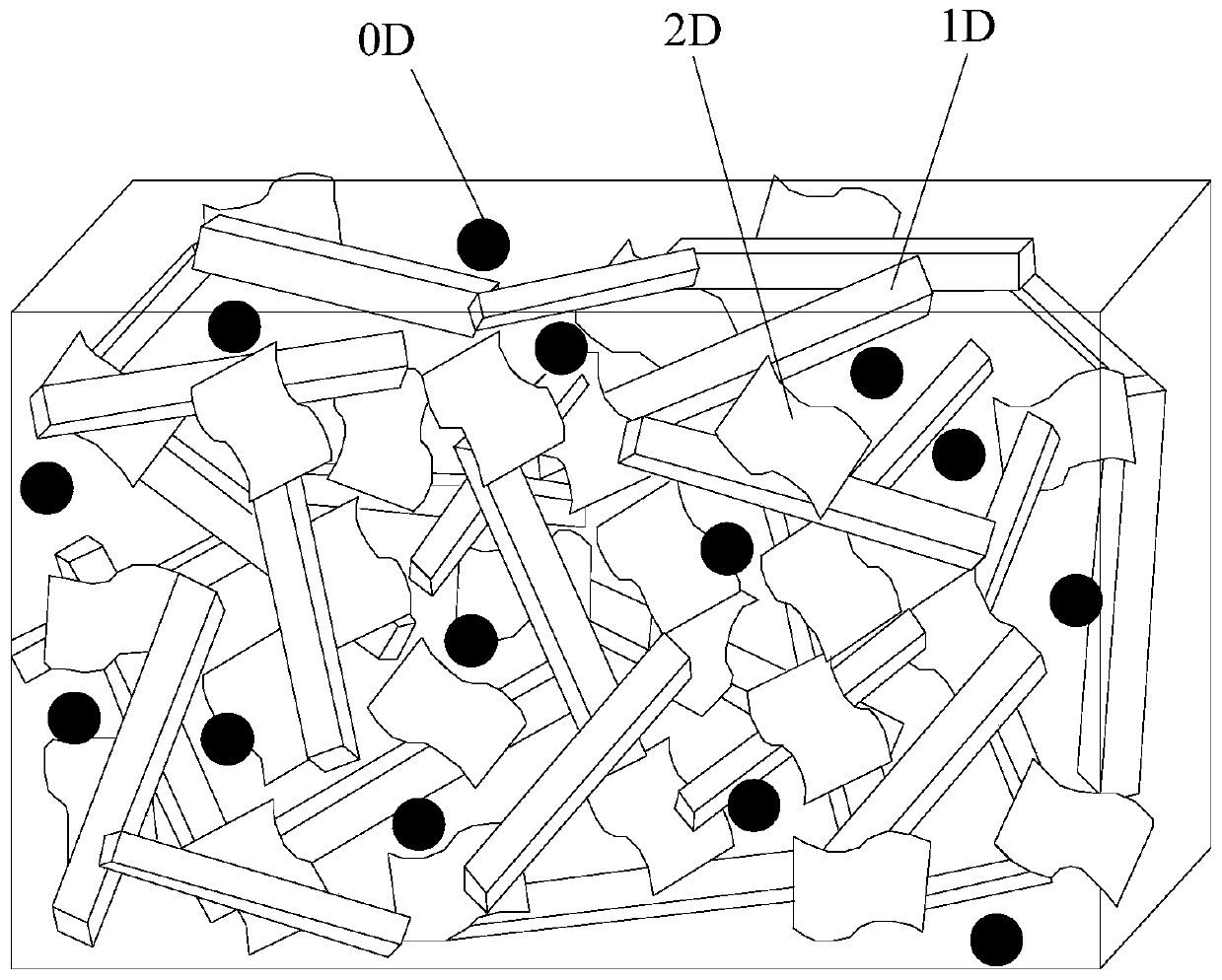

[0028] An embodiment of the present invention provides a conductive additive, which at least includes a micro-nano conductive material, and the micro-nano conductive material includes a zero-dimensional conductive material (0D), a one-dimensional conductive material (1D) and a two-dimensional conductive material (2D). It should be understood that there are various ways of mixing the conductive additive and the matrix resin and other materials provided in the embodiments of the present invention. For details, please refer to the preparation process of the existing conductive polymer composite material, which will not be described in detail here.

[0029] The micro-nano conductive material refers to a conductive material whose size in at least one direction is in the range of 1-1000 microns. The above-mentioned zero-dimensional conductive material is a micro-nano-sized spherical structure microscopically. One-dimensional conductive materials are microscopically in the form of wi...

Embodiment 2

[0064] An embodiment of the present invention provides an application of a conductive additive in a conductive composite material. Based on this, an embodiment of the present invention also provides a conductive composite material. The conductive composite material includes a matrix resin and the above-mentioned conductive additive, so as to realize the beneficial effects achieved by the above-mentioned conductive additive.

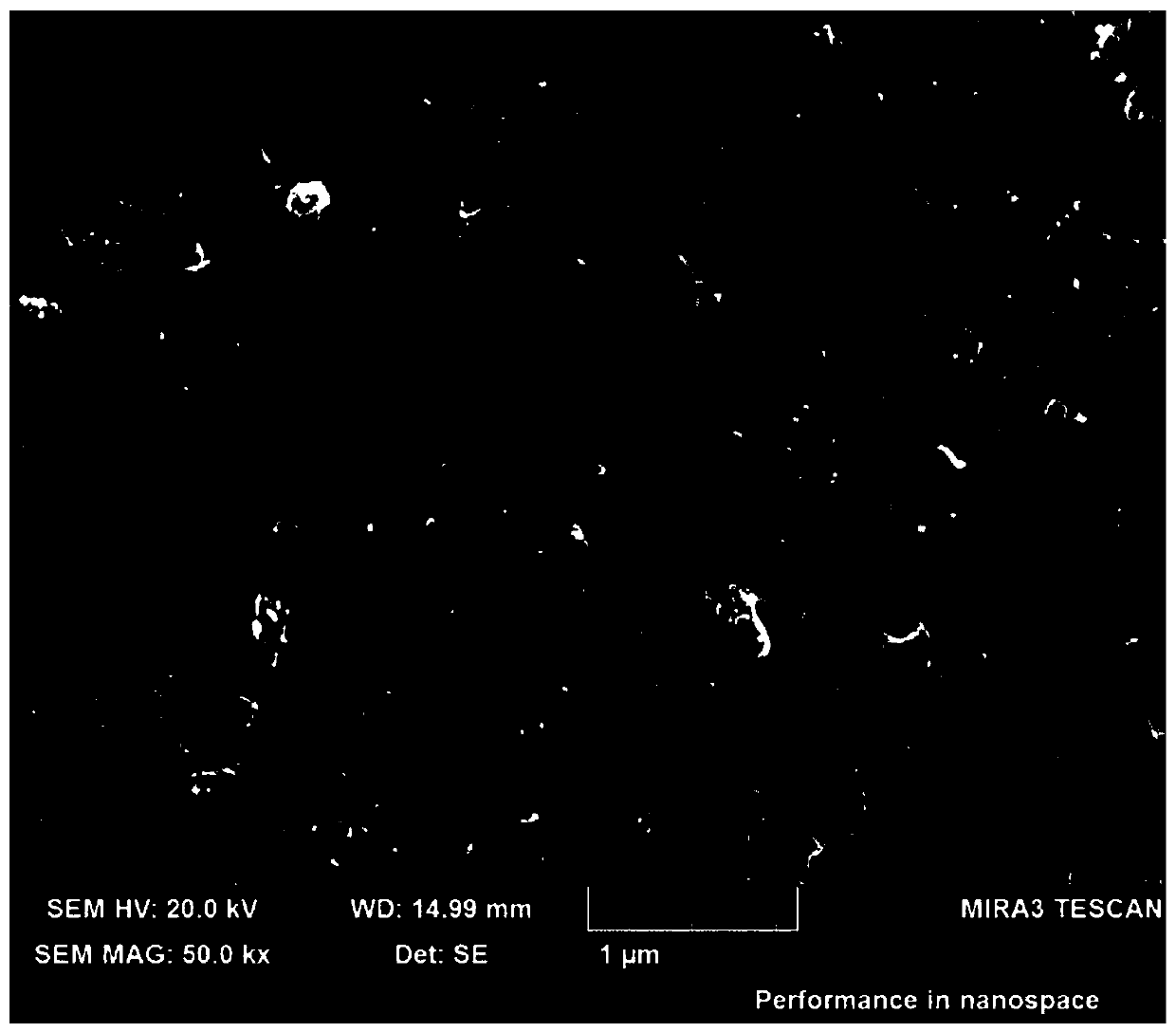

[0065] Exemplary, figure 2 A scanning electron microscope image of the conductive composite material provided by the embodiment of the present invention is shown. figure 2 The flakes are graphene as a two-dimensional conductive material, the filaments are nanotubes, and the blocks are carbon black. Depend on figure 2 It can be seen that graphene, nanotubes and carbon black interact with each other to make up for the gaps generated during the material accumulation process, making the formed "point-line-plane" space conductive network structure relati...

Embodiment 3

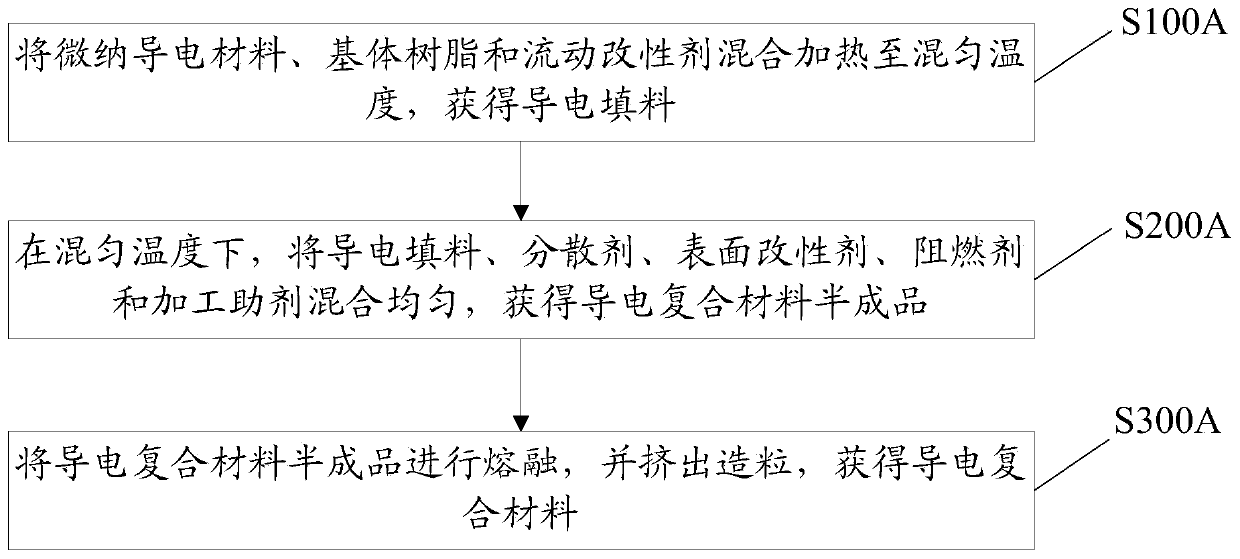

[0073] The embodiment of the invention also provides a preparation method of the conductive composite material. The preparation method of the conductive composite material comprises:

[0074] The conductive composite material is obtained by dispersing the conductive additive in the matrix resin, and the conductive additive is the conductive composite material described in Example 1, so that the preparation method of the conductive composite material provided in the embodiment of the present invention can achieve the beneficial effect of the above-mentioned conductive additive.

[0075] In some embodiments, in the prior art, when the one-dimensional conductive material contained in the above-mentioned conductive additive includes at least one of nanowires, nanorods, and nanotubes, and the above-mentioned two-dimensional conductive material includes graphene, the one-dimensional conductive material The large specific surface area of graphene makes it easy to agglomerate when p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com