Flame-retardant high-impact polystyrene composite material and preparation method thereof

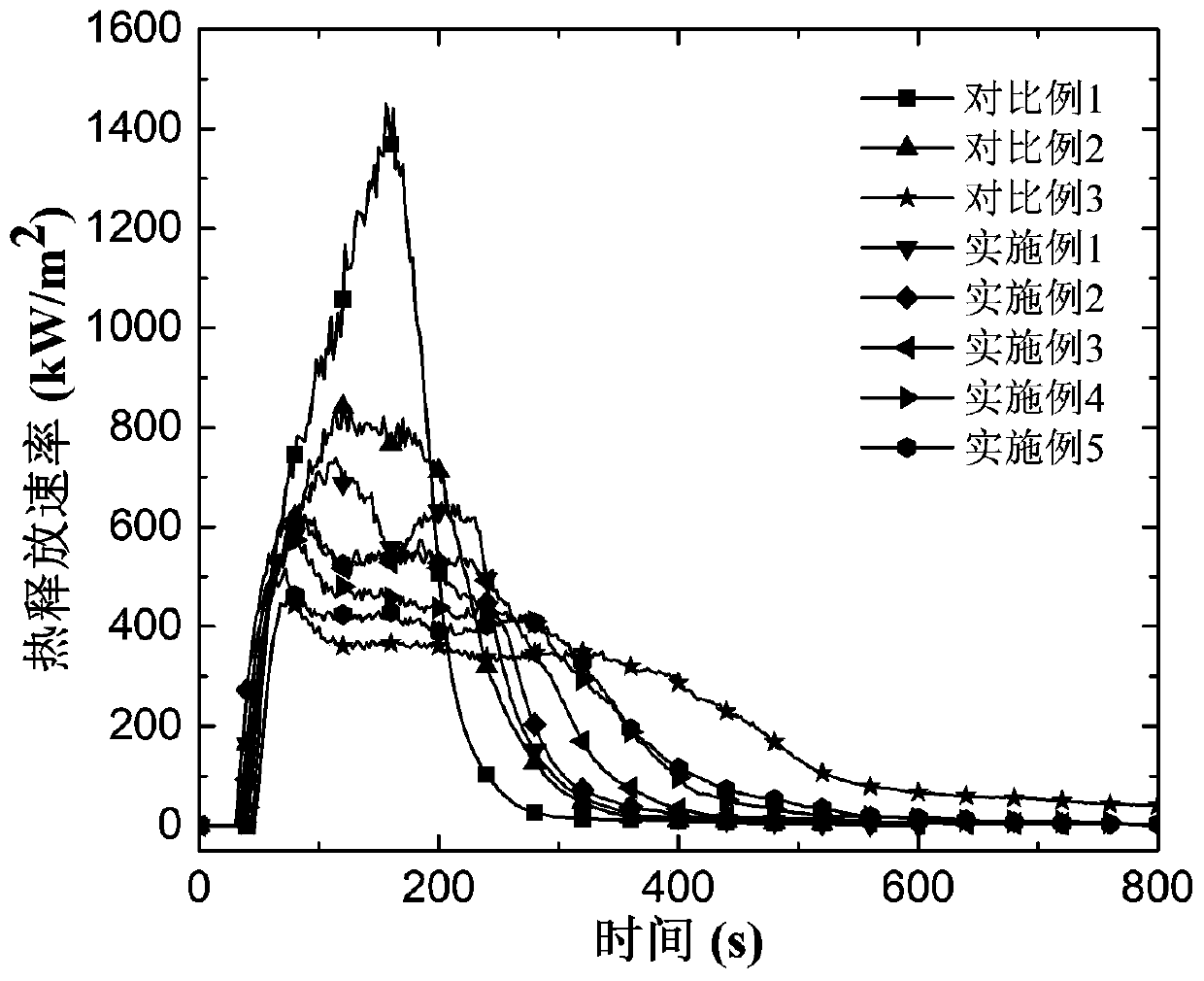

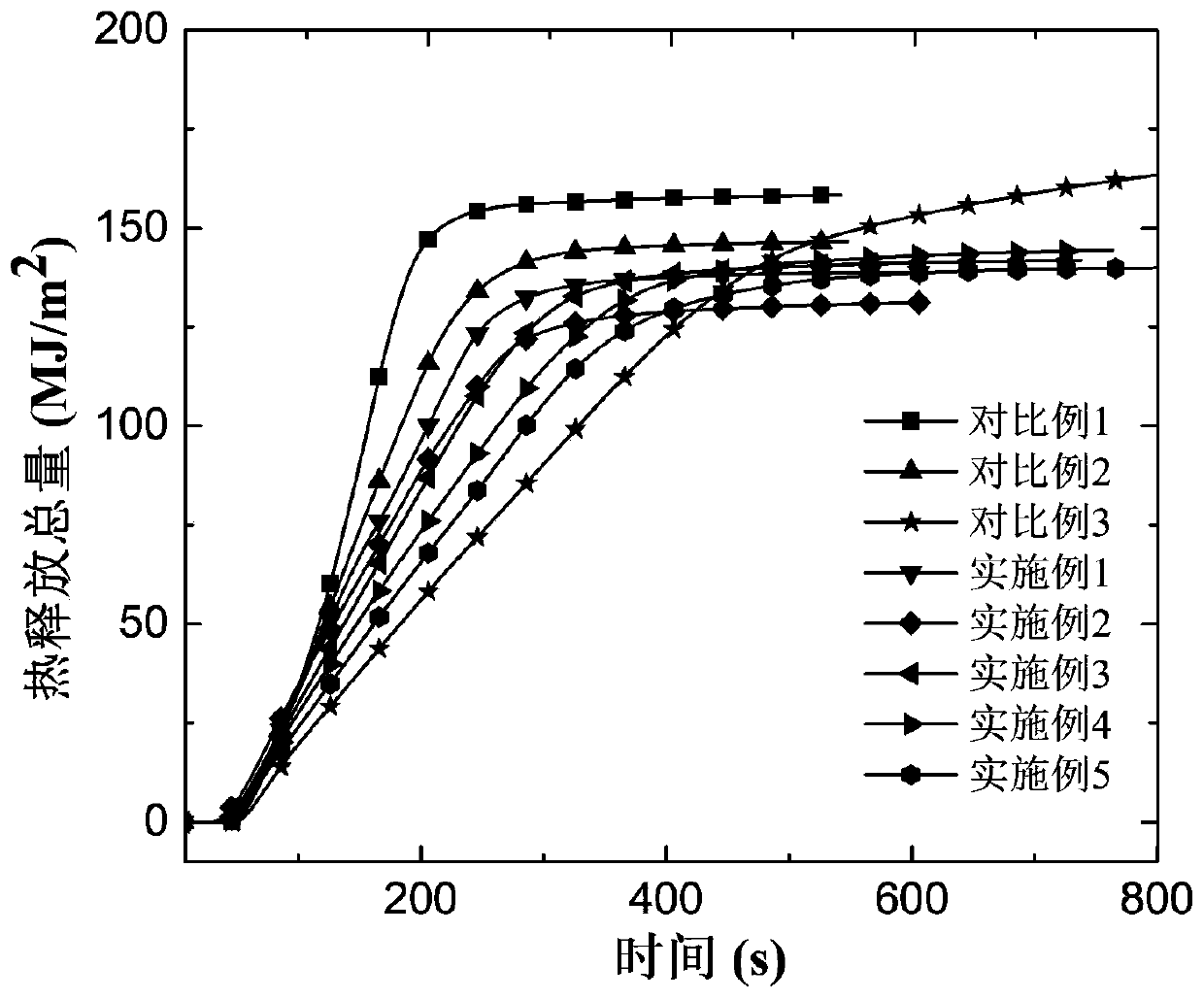

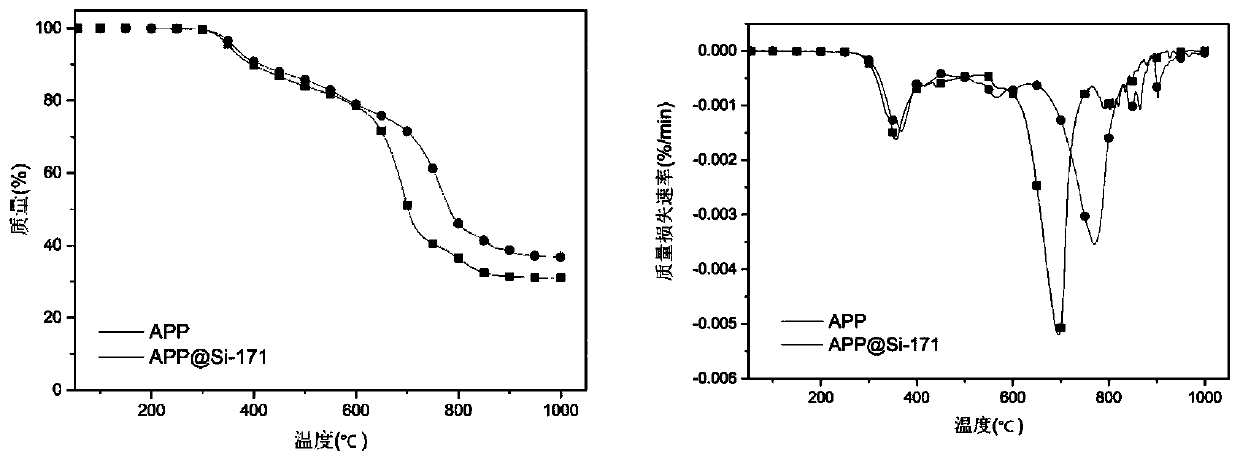

A technology of polystyrene and composite materials, which is applied in the field of polymer flame retardant materials, can solve problems such as limiting the scope of application, and achieve the effects of increasing the amount of carbon residue, improving thermal stability, and reducing the peak value of heat release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Preparation of high-impact polystyrene / modified ammonium polyphosphate / graphene composite (12:85:3)

[0052] Add 1.5 g of silane coupling agent Si-171 to 50 mL of absolute ethanol and stir for 11 min, heat the stirred solution to 90° C., and stir for 55 min to obtain solution A.

[0053] Disperse 50g of ammonium polyphosphate in 200mL of absolute ethanol, stir well to disperse it evenly, the stirring time is 33min, and obtain solution B. Then solution B was added to solution A, keeping the temperature of the reaction system at 45°C, fully reacting for 130min under stirring to obtain product C. Finally, product C was subjected to suction filtration, dried in a vacuum oven at 90° C. for 4.5 hours, ground and pulverized, and then passed through a 300-mesh sieve to obtain modified product D (the stirring speeds above were all 500 r / min).

[0054] Add the modified product D, high-impact polystyrene and graphene into the torque rheometer at a ratio of 12:85:3, adjust the ...

Embodiment 2

[0058] 1. Preparation of high-impact polystyrene / modified ammonium polyphosphate / graphene composite (9:85:6)

[0059] Add 1.5 g of silane coupling agent Si-171 to 50 mL of absolute ethanol and stir for 13 min, heat the stirred solution to 90° C., and stir for 50 min to obtain solution A.

[0060] Disperse 50g of ammonium polyphosphate in 200mL of absolute ethanol, stir well to disperse evenly, and stir for 28min to obtain solution B. Then solution B was added to solution A, keeping the temperature of the reaction system at 50°C, and fully reacted for 115 minutes under stirring to obtain product C. Finally, product C was subjected to suction filtration, dried in a vacuum oven at 85° C. for 5 hours, ground and pulverized, and passed through a 300-mesh sieve to obtain modified product D (the above stirring speeds were all 400 r / min).

[0061] Add the modified product D, high-impact polystyrene and graphene into the torque rheometer at a ratio of 9:85:6, adjust the roll temperatu...

Embodiment 3

[0065] 1. Preparation of high-impact polystyrene / modified ammonium polyphosphate / graphene composite (7.5:85:7.5)

[0066] Add 1.5 g of silane coupling agent Si-171 to 50 mL of absolute ethanol and stir for 8 min, heat the stirred solution to 85° C., and stir for 65 min to obtain solution A.

[0067] Disperse 50g of ammonium polyphosphate in 200mL of absolute ethanol, stir well to disperse evenly, the stirring time is 34min, and obtain solution B. Then solution B was added to solution A, keeping the temperature of the reaction system at 55°C, and fully reacted for 125 minutes under stirring to obtain product C. Finally, product C was subjected to suction filtration, dried in a vacuum oven at 95° C. for 4 hours, ground and pulverized, and then passed through a 300-mesh sieve to obtain modified product D (the above stirring speeds were all 300 r / min).

[0068] Add the modified product D, high-impact polystyrene and graphene into the torque rheometer at a ratio of 7.5:85:7.5, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com