Nano silicon dioxide and intumescent flame retardant synergistic flame-resistance polypropylene/ethylene propylene diene monomer rubber composite material and preparation method thereof

A technology of nano-silica and EPDM, applied to intumescent flame-retardant polypropylene/EPDM composite materials, synergistic flame-retardant polypropylene/EPDM composite materials and their preparation, nano In the field of silica and expanded flame-retardant polypropylene/EPDM composite materials and their preparation, they can solve the problems of decreased mechanical properties, poor compatibility, and poor dispersion of materials, and achieve improved mechanical properties, improved compatibility, and improved resistance. The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

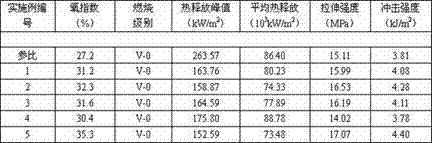

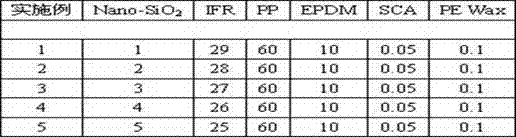

[0024] The proportioning of table 1 embodiment 1-5

[0025]

Embodiment 1

[0027] The preparation method of embodiment 1

[0028] A method for preparing a synergistic flame-retardant polypropylene / EPDM composite material of nano-silica and intumescent flame retardant, comprising the steps of:

[0029] (1) Prepare ammonium polyphosphate, dipentaerythritol, and melamine in proportion to form an intumescent flame retardant, and dry it in an oven at 120°C for 2 hours together with nano-silica, and set it aside.

[0030] (2) Dissolve the silane coupling agent in 10 times its volume of anhydrous methanol to make a coupling agent / methanol solution, spray it on the surface of the intumescent flame retardant and nano-silica, and mix it in a high-speed mixer to improve After drying for 10 minutes, take it out, and then place it in an oven at 120°C to dry for 2 hours to obtain a surface-modified intumescent flame retardant and nano-silica (dry surface modification).

[0031] (3) According to the ratio in Table 1, mix the surface-modified nano-silica / intumescen...

Embodiment 2

[0032] The preparation method of embodiment 2

[0033] A method for preparing a synergistic flame-retardant polypropylene / EPDM composite material of nano-silica and intumescent flame retardant, comprising the steps of:

[0034] (1) Prepare ammonium polyphosphate, dipentaerythritol, and melamine in proportion to form an intumescent flame retardant, and dry it in an oven at 120°C for 2 hours together with nano-silica, and set it aside.

[0035] (2) Dissolve the silane coupling agent in 10 times its volume of anhydrous methanol to make a coupling agent / methanol solution, spray it on the surface of the intumescent flame retardant and nano-silica, and mix it in a high-speed mixer to improve After drying for 10 minutes, take it out, and then place it in an oven at 120°C to dry for 2 hours to obtain a surface-modified intumescent flame retardant and nano-silica (dry surface modification).

[0036](3) According to the ratio in Table 1, mix the surface-modified nano-silica / intumescent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com