Flame-retardant smoke-suppressing mineral compound and preparation method and application thereof

A compound and mineral technology, applied in the field of flame retardants, can solve the problems of high price, non-adsorption, and high production costs of smoke suppressants, and achieve enhanced smoke suppression effects, low cost, and good flame retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

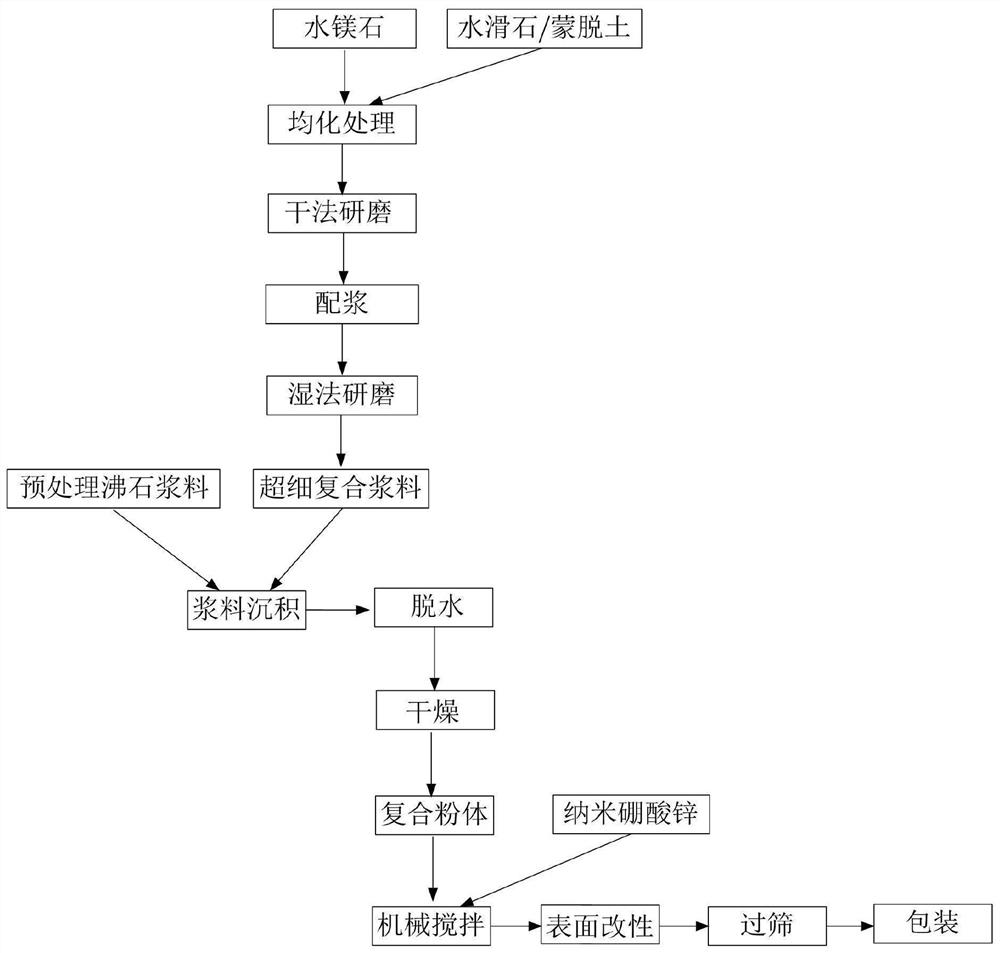

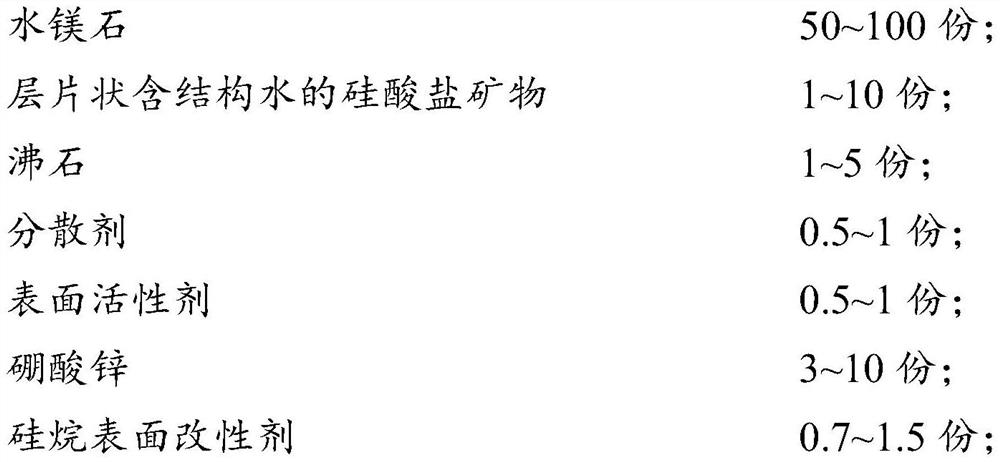

[0043] The present invention provides a preparation method of the above-mentioned flame-retardant and smoke-suppressing mineral compound, comprising the following steps:

[0044] (1) Mix brucite, lamellar silicate minerals containing structural water, the first dispersant with water, and perform the first wet grinding to obtain a premixed mineral slurry;

[0045] (2) mixing zeolite, surfactant and water, and performing second wet grinding to obtain zeolite slurry;

[0046] (3) mixing the premixed mineral slurry, the zeolite slurry and the second dispersant, adjusting the pH value of the resulting mixed solution to 8.5-10, performing liquid phase deposition, solid-liquid separation and drying in sequence to obtain a mixed powder;

[0047] (4) mixing the mixed powder with zinc borate and a silane surface modifier to obtain a flame-retardant and smoke-suppressing mineral compound;

[0048] There is no time sequence limitation between the step (1) and the step (2).

[0049] The ...

Embodiment 1

[0065] The raw ore of brucite with MgO content of 62% and hydrotalcite were homogenized at a mass ratio of 10:1 and then dry-ground to obtain a 325-mesh powder. The dry-ground powder was mixed with water to make a slurry with a solid content of 35%. Add 7‰ sodium polyacrylate and sodium oleate in the process of preparing slurry, and carry out wet grinding. The temperature of wet grinding is 65°C, the grinding time is 60min, and the viscosity of the system is 250mpa / s; obtained after wet grinding The ultra-fine composite slurry and the pretreated zeolite slurry are subjected to liquid phase deposition. The stirring speed of liquid phase deposition is 60r / min, the temperature is 65°C, and the deposition time is 2h. Adjust the pH value of the slurry to 9.5; after dehydration and drying, the composite powder is mechanically stirred and compounded with nano-zinc borate accounting for 5% of the total weight of the powder, the stirring speed is 300r / min, and the temperature is 100 °C;...

Embodiment 2

[0068] The raw ore of brucite with MgO content of 60% and montmorillonite were homogenized at a mass ratio of 6:1 and then dry-ground to obtain a 325-mesh powder. The dry-ground powder was mixed with water to have a solid content of 30%. Slurry, add 9‰ sodium polyacrylate and polyaminoamide phosphate in the process of preparing slurry, and carry out wet grinding. The temperature of wet grinding is 75°C, the grinding time is 80min, and the viscosity of the system is 300mpa / s; wet grinding The obtained ultrafine composite slurry and the pretreated zeolite slurry are subjected to liquid phase deposition, the liquid phase deposition stirring speed is 75r / min, the temperature is 75°C, the deposition time is 3h, and the powder mass of 5‰ ammonium polyacrylate is added Dispersant, adjust the pH value of the slurry to 9.5; the composite powder obtained after dehydration and drying is mechanically stirred and compounded with nano-zinc borate accounting for 3% of the total weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com