Halogen-free low-smoke ethylene-vinyl acetate inner sheath material for B1-level flame-retardant cable and preparation method

A technology of vinyl acetate and flame-retardant cables, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., and can solve the problems of failing to meet the requirements of B1-level flame-retardant cables, and achieve dripping non-flammability, Effect of low water absorption and low heat release rate/volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

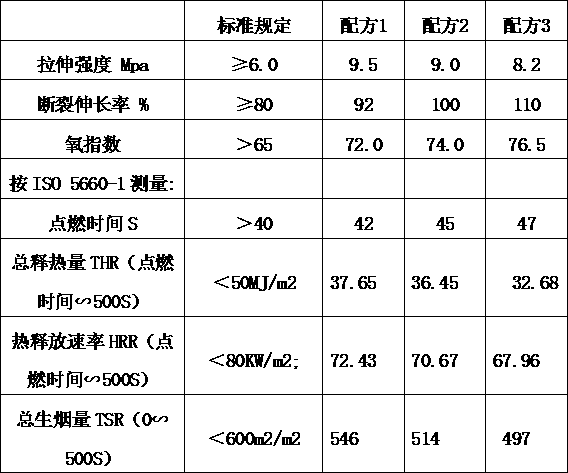

Examples

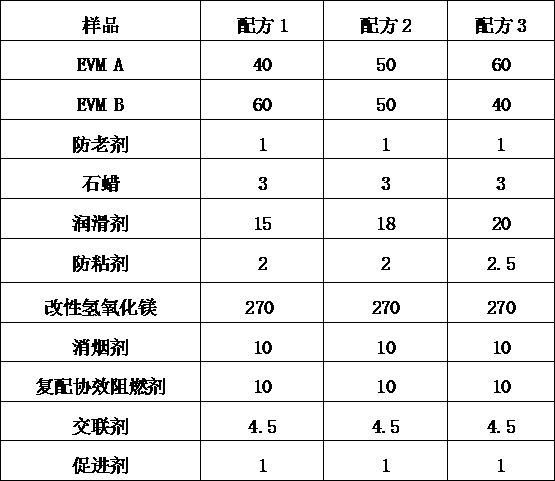

Embodiment 1

[0024] A thermosetting halogen-free, low-smoke, low-heat-of-burning, and high-flame-retardant ethylene-vinyl acetate rubber outer sheath material for B1 flame-retardant subway DC traction cables, characterized in that it is prepared from the following components in parts by weight:

[0025] 40 parts of ethylene-vinyl acetate copolymer A (80% VA content);

[0026] Ethylene-vinyl acetate copolymer B (40% VA content) 60 parts;

[0027] 270 parts of special silane-modified magnesium hydroxide;

[0028] 5 parts of smoke suppressant;

[0029] 3 parts of paraffin;

[0030] 15 parts of lubricant;

[0031] 2 parts of anti-sticking agent;

[0032] 1 part of anti-aging agent;

[0033] 10 parts of compound synergistic flame retardant;

[0034] 4.5 parts of cross-linking agent;

[0035] 1 part of accelerator;

[0036] Its preparation steps are as follows:

[0037] (1) First weigh the raw materials according to the proportion by weight, in the upper auxiliary machine, mix ethylene-...

Embodiment 2

[0040] A thermosetting halogen-free, low-smoke, low-heat-of-combustion, ultra-flame-retardant ethylene-vinyl acetate rubber inner sheath material for B1 flame-retardant subway DC traction cables, characterized in that it is prepared from the following components in parts by weight:

[0041] Ethylene-vinyl acetate copolymer A (80% VA content) 50 parts;

[0042] Ethylene-vinyl acetate copolymer B (40% VA content) 50 parts;

[0043] 270 parts of specially modified magnesium hydroxide;

[0044] 5 parts of smoke suppressant;

[0045] 3 parts of paraffin;

[0046] 18 parts of lubricant;

[0047] 2 parts of anti-sticking agent;

[0048] 1 part of anti-aging agent;

[0049] 10 parts of compound synergistic flame retardant;

[0050] 4.5 parts of cross-linking agent;

[0051] 1 part of accelerator;

[0052] Its preparation steps are as follows:

[0053] (1) First weigh the raw materials according to the proportion by weight, in the upper auxiliary machine, mix ethylene-vinyl acet...

Embodiment 3

[0056] A thermosetting halogen-free, low-smoke, low-heat-of-combustion, ultra-flame-retardant ethylene-vinyl acetate rubber inner sheath material for B1 flame-retardant subway DC traction cables, characterized in that it is prepared from the following components in parts by weight:

[0057] Ethylene-vinyl acetate copolymer A (80% VA content) 60 parts;

[0058] 40 parts of ethylene-vinyl acetate copolymer B (40% VA content);

[0059] 270 parts of special silane-modified magnesium hydroxide;

[0060] 5 parts of smoke suppressant;

[0061] 3 parts of paraffin;

[0062] 20 parts of lubricant;

[0063] 2.5 parts of anti-sticking agent;

[0064] 1 part of anti-aging agent;

[0065] 10 parts of compound synergistic flame retardant;

[0066] 4.5 parts of cross-linking agent;

[0067] 1 serving of accelerator.

[0068] Its preparation steps are as follows:

[0069] (1) First weigh the raw materials according to the proportion by weight, in the upper auxiliary machine, mix ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com