Low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and preparation method thereof

An unsaturated, low-shrinkage technology, applied in the field of low-shrinkage, medium-temperature curing, high-efficiency flame-retardant unsaturated polyester glass fiber reinforced plastic sheet and its preparation, can solve the limitation of flame-retardant performance, does not meet the requirements of environmental protection, and cannot achieve the highest flame-retardant effect. level and other issues, to achieve the effect of low curing shrinkage, protection of life, health and safety, and reduction of smoke toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

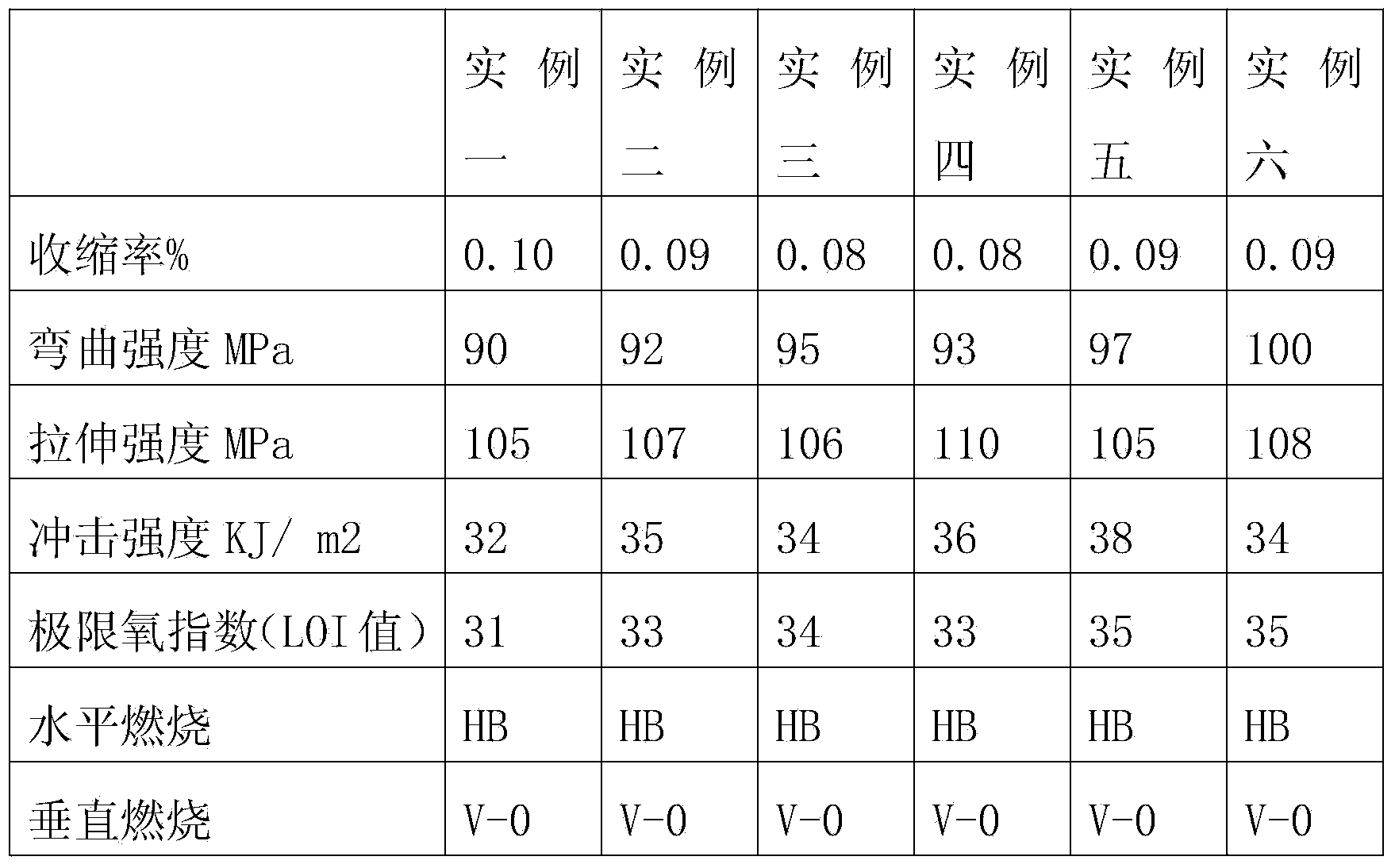

Examples

Embodiment 1

[0022] A low-shrinkage medium-temperature curing high-efficiency flame-retardant unsaturated polyester fiberglass plate, which is made of the following raw materials in weight ratio:

[0023] Bisphenol A type unsaturated polyester resin 50 parts

[0024] Polyvinyl acetate and polymethyl methacrylate block copolymer 20 parts

[0025] 1 part cobalt isooctanoate

[0026] Dibenzoyl peroxide 0.5 parts

[0027] 2 parts methyl ethyl ketone peroxide

[0028] 0.15 parts of light magnesium oxide

[0029] Dimethyl methylphosphonate flame retardant 8 parts

[0030] Aluminum hydroxide 100 parts

[0032] 100 parts glass fiber

[0033] The preparation method is:

[0034] (1) First add bisphenol A type unsaturated polyester resin, polyvinyl acetate and polymethyl methacrylate block copolymer, and cobalt isooctanoate in the above ratio into the beater, and stir rapidly for 3 minutes;

[0035] (2) Add dibenzoyl peroxide, methyl ethyl ketone peroxide, and ...

Embodiment 2

[0038] A low-shrinkage medium-temperature curing high-efficiency flame-retardant unsaturated polyester fiberglass plate, which is made of the following raw materials in weight ratio:

[0039] Bisphenol A type unsaturated polyester resin 52 parts

[0040] Polyvinyl acetate and polymethyl methacrylate block copolymer 22 parts

[0041] 2 parts cobalt isooctanoate

[0042] Dibenzoyl peroxide 0.8 parts

[0043] 3 parts methyl ethyl ketone peroxide

[0044] 0.2 parts of light magnesium oxide

[0045] Dimethyl methylphosphonate flame retardant 10 parts

[0046] Aluminum hydroxide 110 parts

[0048] Glass fiber 110 parts

[0049] Preparation:

[0050] (1) First add bisphenol A type unsaturated polyester resin, polyvinyl acetate and polymethyl methacrylate block copolymer, and cobalt isooctanoate in the above ratio into the beater, and stir rapidly for 3 minutes;

[0051] (2) Add dibenzoyl peroxide, methyl ethyl ketone peroxide, and light magnesi...

Embodiment 3

[0054] A low-shrinkage medium-temperature curing high-efficiency flame-retardant unsaturated polyester fiberglass plate, which is made of the following raw materials in weight ratio:

[0055] Bisphenol A type unsaturated polyester resin 54 parts

[0056] Polyvinyl acetate and polymethyl methacrylate block copolymer 24 parts

[0057] 2 parts cobalt isooctanoate

[0058] Dibenzoyl peroxide 1.1 parts

[0059] 4 parts methyl ethyl ketone peroxide

[0060] 0.3 parts of light magnesium oxide

[0061] Dimethyl methylphosphonate flame retardant 13 parts

[0062]Aluminum hydroxide 110 parts

[0064] 120 parts glass fiber

[0065] Preparation:

[0066] (1) First add bisphenol A type unsaturated polyester resin, polyvinyl acetate and polymethyl methacrylate block copolymer, and cobalt isooctanoate in the above ratio into the beater, and stir rapidly for 3 minutes;

[0067] (2) Add dibenzoyl peroxide, methyl ethyl ketone peroxide, and light magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com