Bio-based nano synergistic flame retardant, and preparation method and application thereof

A synergistic flame retardant and bio-based technology, applied in the field of flame retardant, can solve the environmental pollution problems of halogen flame retardants, achieve the effects of simple production process, reduced smoke toxicity, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

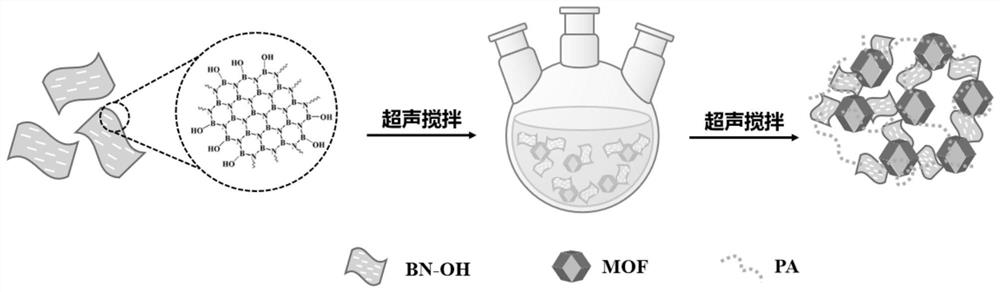

[0033] Please refer to the attached figure 1 , the two-dimensional material is hydroxylated boron nitride, and the preparation method mainly includes:

[0034] S1. Take an appropriate amount of hydroxylated boron nitride and add it to an appropriate amount of methanol, and ultrasonically disperse to obtain a hydroxylated boron nitride suspension;

[0035] S2. Take an appropriate amount of transition metal salt compound and dissolve it in an appropriate amount of methanol, add it dropwise to the above-mentioned hydroxylated boron nitride suspension, and stir evenly;

[0036] S3. Dissolve an appropriate amount of 2-methylimidazole in an appropriate amount of methanol, dropwise add it to the mixed solution in step S2, and after ultrasonic stirring and reaction, centrifuge to obtain the product, wash it with deionized water or ethanol for 2 to 5 times, and then wash it at 50 Dry in an oven at ~80°C for 3-10 hours to obtain intermediate products;

[0037] S4. Take an appropriate ...

Embodiment 1

[0039] S1. Add 0.252 g of hydroxylated boron nitride into 25 mL of methanol, and ultrasonically disperse for 30 minutes to obtain a suspension of hydroxylated boron nitride;

[0040] S2, take 0.743g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 25mL of methanol, added dropwise to the suspension of hydroxylated boron nitride, and stirred for 10min;

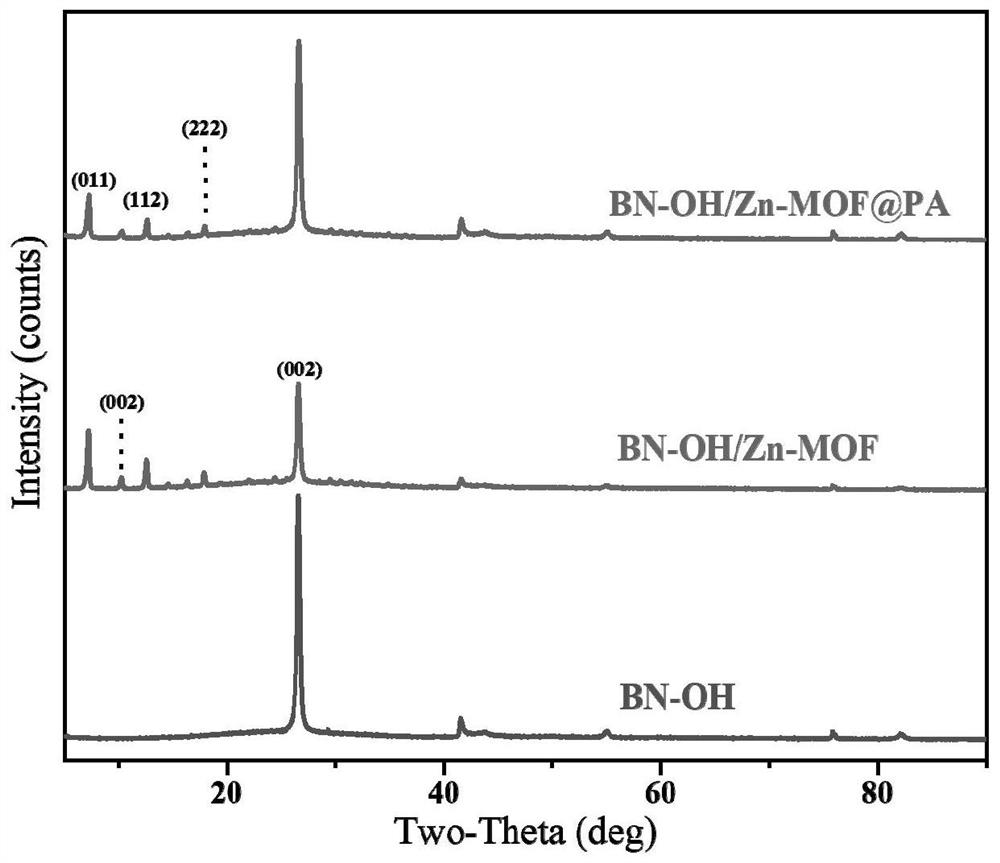

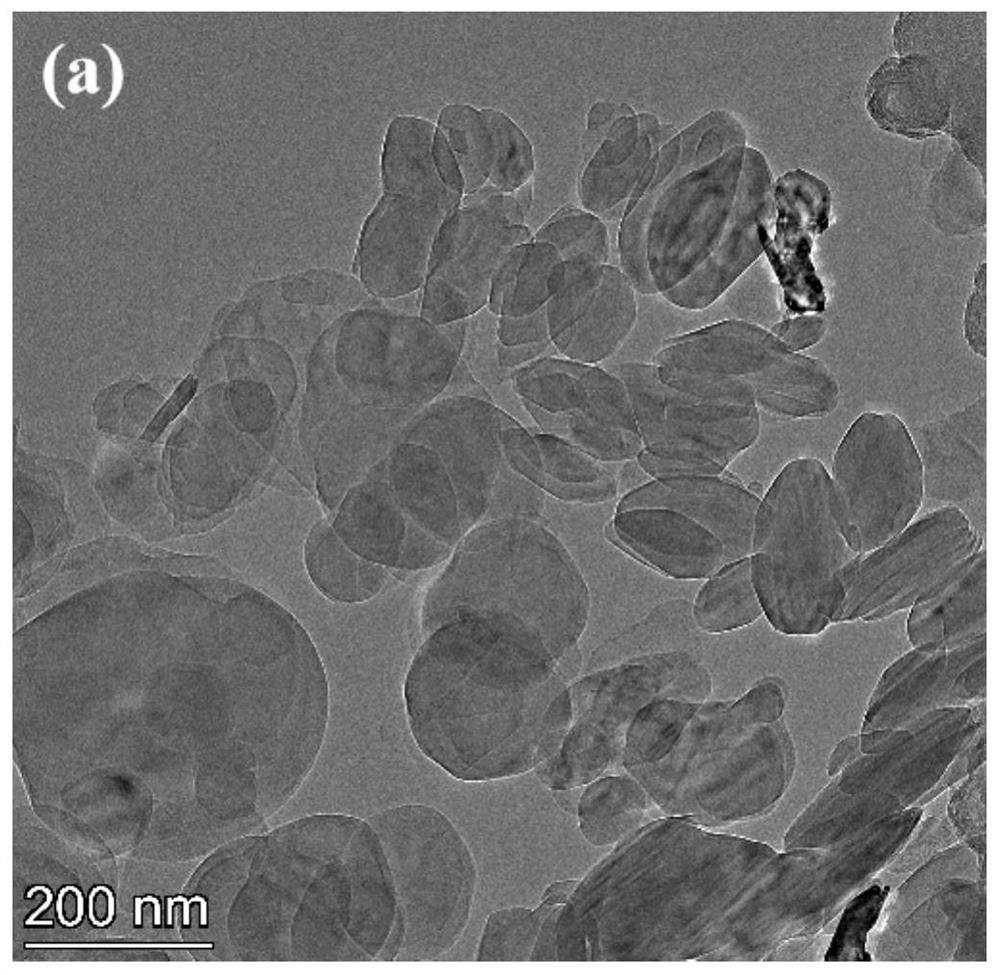

[0041] S3. Dissolve 0.415g of 2-methylimidazole in 25mL of methanol, add it dropwise to the mixed solution in step S2, sonicate for 60min, stir for 12h, centrifuge, wash with deionized water or ethanol for 3 times, and place in an oven at 60°C Dry for 10 hours to obtain BN-OH / Zn-MOF;

[0042] S4. Take 0.01g of BN-OH / Zn-MOF powder and disperse it in 25mL of methanol. After forming a uniform suspension, add 0.1mL of 0.5wt% phytic acid, and stir the reaction at room temperature. After the reaction, centrifuge, remove The BN-OH / Zn-MOF@PA flame retardant was obtained by washing with ionized water or ethanol three times, and drying in an oven...

Embodiment 2

[0050] S1. Add 0.252 g of hydroxylated boron nitride into 25 mL of methanol, and ultrasonically disperse for 30 minutes to obtain a suspension of hydroxylated boron nitride;

[0051] S2, take 1.296g Co(NO 3 ) 2 ·6H 2 O was dissolved in 50 mL of methanol, added dropwise to the suspension of hydroxylated boron nitride, and stirred for 1 h;

[0052] S3. Dissolve 1.77g of 2-methylimidazole in 50mL of methanol, add dropwise to the mixed solution in step S2, sonicate for 80min, stir for 10h, centrifuge, wash with ethanol for 4 times, and dry in an oven at 60°C for 10h to obtain BN -OH / Co-MOF;

[0053] S4. Take 0.01g BN-OH / Co-MOF powder and disperse it in 25mL of methanol. After forming a uniform suspension, add 0.2mL of 0.5wt% phytic acid, and stir the reaction at room temperature. After the reaction, centrifuge, ethanol After washing 4 times, the BN-OH / Co-MOF@PA flame retardant was obtained by drying in an oven at 60 °C for 10 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com