Inorganic material filled flame retardant PP material and preparation method thereof

A technology of inorganic materials and flame retardants is applied in the material field of rail vehicles to achieve the effects of improving mechanical properties, low smoke density and low smoke toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the flame-retardant PP material filled with inorganic materials is as follows:

[0051] After mixing each raw material in a high-speed mixer for 5 minutes, the mixture is placed in a twin-screw extruder. The processing technology is: the temperature of the first zone is 170-180°C, the temperature of the second zone is 175-185°C, and the temperature of the third zone is 180 -190°C, the temperature of the fourth zone is 180-190°C, the temperature of the fifth zone is 180-190°C, the temperature of the machine head is 180-200°C, and the speed of the main engine is 300-500 rpm. Extrusion and granulation can obtain flame-retardant PP materials for rail vehicles.

Embodiment 1-3

[0053] Table 1 is the formulation of the flame-retardant PP material filled with inorganic materials in Examples 1-3.

[0054] Table 1

[0055]

[0056]

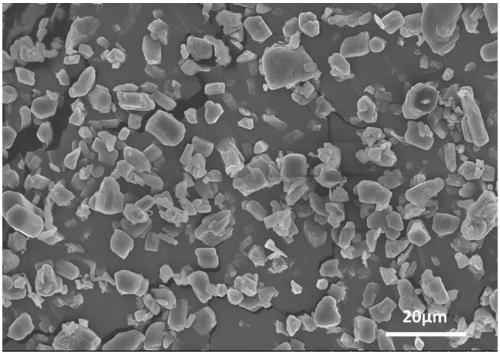

[0057] Among them, the scanning electron microscope picture of piperazine pyrophosphate A is as follows figure 1 As shown, its average particle size is about 0.1 μm-10 μm.

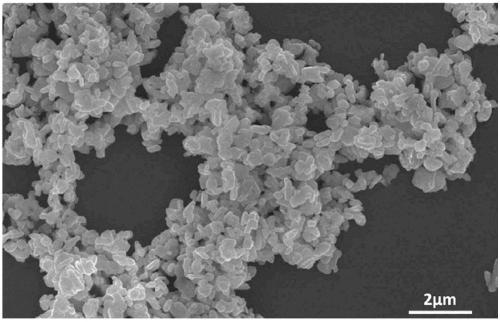

[0058] The scanning electron microscope image of molybdenum disulfide C figure 2 As shown, its average particle size is about 0.01 μm-1 μm.

[0059] The antioxidant is a mixture of hindered phenolic antioxidant 1010 and phosphite antioxidant 168 in a mass ratio of 1:1.

[0060] PP resin is a mixture of homopolymerized PP and copolymerized PP in a mass ratio of 4:1.

[0061] The mesh number of talcum powder is 3000 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com