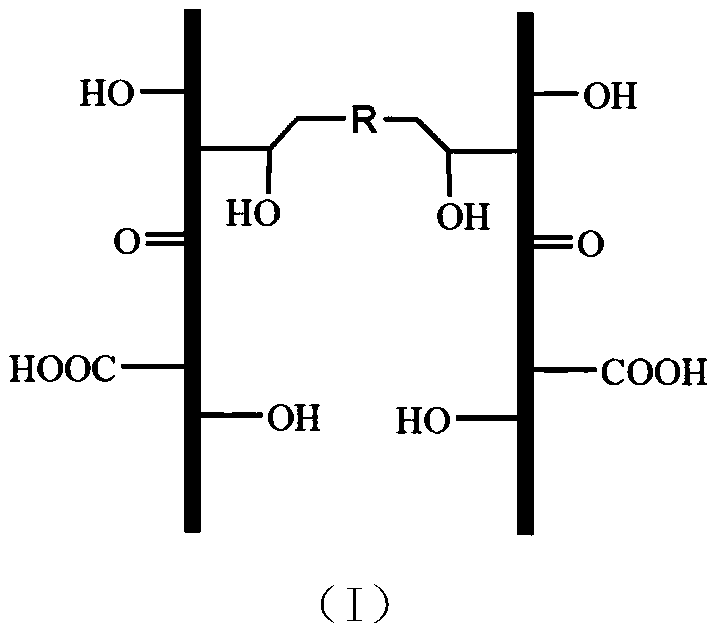

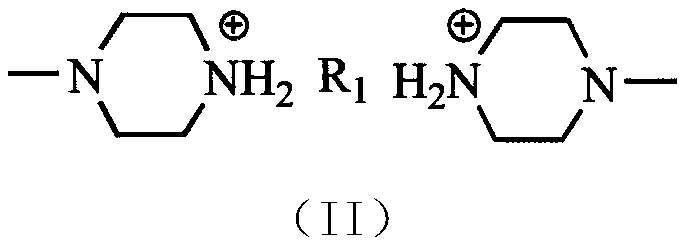

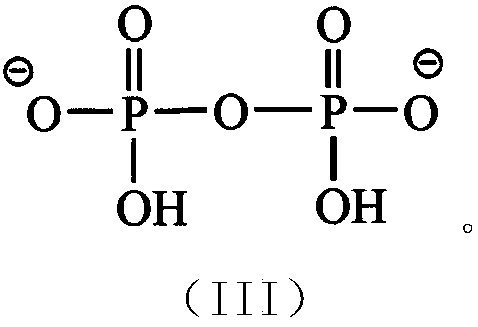

Graphene/piperazine pyrophosphate nano composite and preparation method thereof

A technology of piperazine pyrophosphate and nanocomposite, which is applied in chemical instruments and methods, materials for heat exchange, organic chemistry, etc. Low cost, the effect of solving the problem of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the graphene / piperazine pyrophosphate nanocomposite of the present embodiment comprises the steps:

[0037] Step (1): Add 250mg of GO to 250ml of water, ultrasonically stir GO to make it fully dispersed in water, then add 62.5mg of piperazine, and react at 80°C for 24h to obtain a reaction solution;

[0038] Step (2): Add 73.5 mg of 97% concentrated phosphoric acid to the reaction solution, stir at room temperature for 3 hours to obtain piperazine phosphate salt, separate solid from liquid and wash the resulting solid several times and dry to obtain graphene / piperazine phosphate Salt;

[0039] Step (3): Place the graphene / piperazine phosphate salt obtained in step (2) in a rotary furnace, set the temperature at 230° C., and protect it with nitrogen gas, and heat at a constant temperature for 12 hours to prepare a graphene / piperazine pyrophosphate nanocomposite things.

[0040] The graphene / piperazine pyrophosphate nanocomposite obtained in th...

Embodiment 2

[0042] The preparation method of the graphene / piperazine pyrophosphate nanocomposite of the present embodiment comprises the steps:

[0043] Step (1): Add 250mg of GO to 250ml of water, ultrasonically stir GO to make it fully dispersed in water, then add 62.5mg of piperazine, and react at 80°C for 24h to obtain a reaction solution;

[0044] Step (2): Add 85.75 mg of 97% concentrated phosphoric acid to the reaction solution, stir at room temperature for 3 h to obtain piperazine phosphate salt, separate solid from liquid and wash the resulting solid several times and dry to obtain graphene / piperazine phosphate Salt;

[0045] Step (3): Place the graphene / piperazine phosphate salt obtained in step (2) in a rotary furnace, set the temperature at 230° C., and protect it with nitrogen gas, and heat at a constant temperature for 12 hours to prepare a graphene / piperazine pyrophosphate nanocomposite thing.

[0046] The graphene / piperazine pyrophosphate nanocomposite obtained in this e...

Embodiment 3

[0048] The preparation method of the graphene / piperazine pyrophosphate nanocomposite of the present embodiment comprises the steps:

[0049] Step (1): Add 250mg of GO to 250ml of water, ultrasonically stir GO to make it fully dispersed in water, then add 75mg of piperazine, and react at 80°C for 24h to obtain a reaction solution;

[0050] Step (2): Add 105 mg of 97% concentrated phosphoric acid to the reaction solution, stir at room temperature for 3 h to obtain piperazine phosphate, separate solid from liquid and wash the resulting solid several times and dry to obtain graphene / piperazine phosphate ;

[0051]Step (3): Place the graphene / piperazine phosphate salt obtained in step (2) in a rotary furnace, set the temperature at 230° C., and protect it with nitrogen gas, and heat at a constant temperature for 12 hours to prepare a graphene / piperazine pyrophosphate nanocomposite things.

[0052] The graphene / piperazine pyrophosphate nanocomposite obtained in this embodiment has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com