A kind of preparation method of low molecular weight chitosan

A low molecular weight, chitosan technology, applied in the field of chitosan degradation, can solve the problems of molecular weight distribution, high degradation efficiency, narrow active amino content, and low active amino content, so as to improve degradation efficiency, energy utilization rate, and color Pure whiteness, activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

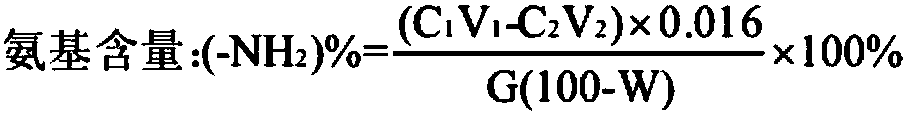

Method used

Image

Examples

Embodiment 1

[0057] Dissolve 8 g of chitosan with a molecular weight of 1.4 million and a degree of deacetylation of 75% in glacial acetic acid solution with a pH value of 3.0 in 100 ml, stir until it dissolves evenly, and then use sodium bicarbonate to adjust the pH value to 9 to obtain a uniform and stable chitosan Chitosan suspension; add 3.2g benzyloxycarbonyl chloride to the above suspension, control the reaction temperature not to exceed 15°C, react for two hours, then add glacial acetic acid solution to adjust the pH value of the system to 3.0, so that the shell The polysaccharide is completely dissolved to obtain a chitosan solution that has completed amino protection.

[0058] Add 1.92g of hydrogen peroxide to the above-mentioned chitosan solution that has completed the amino protection, under the condition of frequency 30KHz, power 25W, ultrasonic at room temperature for 20min, then transfer to a water bath to heat and degrade, control the reaction temperature to 55°C, and add 1.2...

Embodiment 2

[0063] Dissolve 10g of chitosan with a molecular weight of 1.5 million and a degree of deacetylation of 80% in 100ml of citric acid solution with a pH value of 4.5, stir and dissolve evenly, and adjust the pH value to 8 with sodium bicarbonate to obtain a uniform and stable shell Polysaccharide suspension: add 7.0g tert-butoxycarbonyl chloride to the above suspension, control the reaction temperature not to exceed 15°C, react for two hours, then add citric acid solution to adjust the pH value of the system to 4.5, so that the shell The polysaccharide is completely dissolved to obtain a chitosan solution that has completed amino protection.

[0064] Add 2.1g of hydrogen peroxide to the chitosan solution that has completed the amino protection above, at a frequency of 30KHz and a power of 35W, ultrasonicate at room temperature for 30min, then transfer to a water bath for heating and degradation, control the reaction temperature to 60°C, and add 0.9g Hydrogen peroxide, reaction t...

Embodiment 3

[0069] Dissolve 13g of chitosan with a molecular weight of 1.6 million and a degree of deacetylation of 90% in 100ml of citric acid solution with a pH value of 5.0, stir and dissolve evenly, and adjust the pH value to 10 with sodium bicarbonate to obtain a uniform and stable shell Polysaccharide suspension: add 7.8g trimethylsilylethoxycarbonyl chloride to the above suspension, react for two hours, control the reaction temperature below 15°C, and then add citric acid solution to adjust the pH value of the system to 5.0, To make the chitosan dissolve completely, the chitosan solution having completed the amino protection is obtained.

[0070] Add 5.2g of hydrogen peroxide to the above amino-protected chitosan solution, ultrasonicate at room temperature for 35min at a frequency of 40KHz and power of 40W, then transfer to a water bath for heating and degradation, control the reaction temperature at 60°C, and add 3.25g of peroxide Hydrogen, reacted for 1.5 hours.

[0071] After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com