Manufacturing method of polyvinyl butyral film

A technology of polyvinyl butyral and polyvinyl butyral resin, which is applied in the field of polyvinyl butyral film manufacturing to achieve the effects of avoiding aging, preventing discoloration and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment prepares polyvinyl butyral resin according to the following steps:

[0026] (1) Dissolution of polyvinyl alcohol

[0027] Wash polyvinyl alcohol with a degree of polymerization of 1700, a degree of alcoholysis of 99.8%, and a molecular weight distribution of 2.5 with deionized water for 3 times, then prepare a polyvinyl alcohol solution with a mass concentration of 24% with deionized water, and heat to 80°C After heat preservation for 1 hour, the temperature was raised to 100° C. to dissolve completely, then diluted with water to 12%, and filtered under pressure to obtain a polyvinyl alcohol solution.

[0028] (2) Pretreatment of n-butyraldehyde

[0029] The n-butyraldehyde is subjected to vacuum distillation to remove impurities, and the pretreated n-butyraldehyde is sealed with nitrogen for use.

[0030] (3) Synthesis of PVB resin

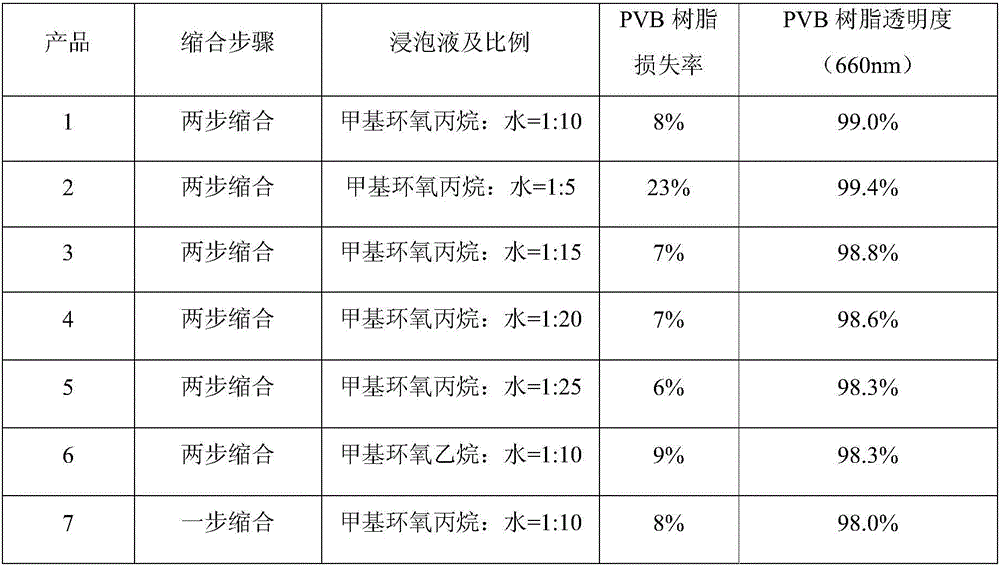

[0031] With the treated 400g polyvinyl alcohol solution and 240g n-butyraldehyde as raw materials, with 60g mas...

Embodiment 2

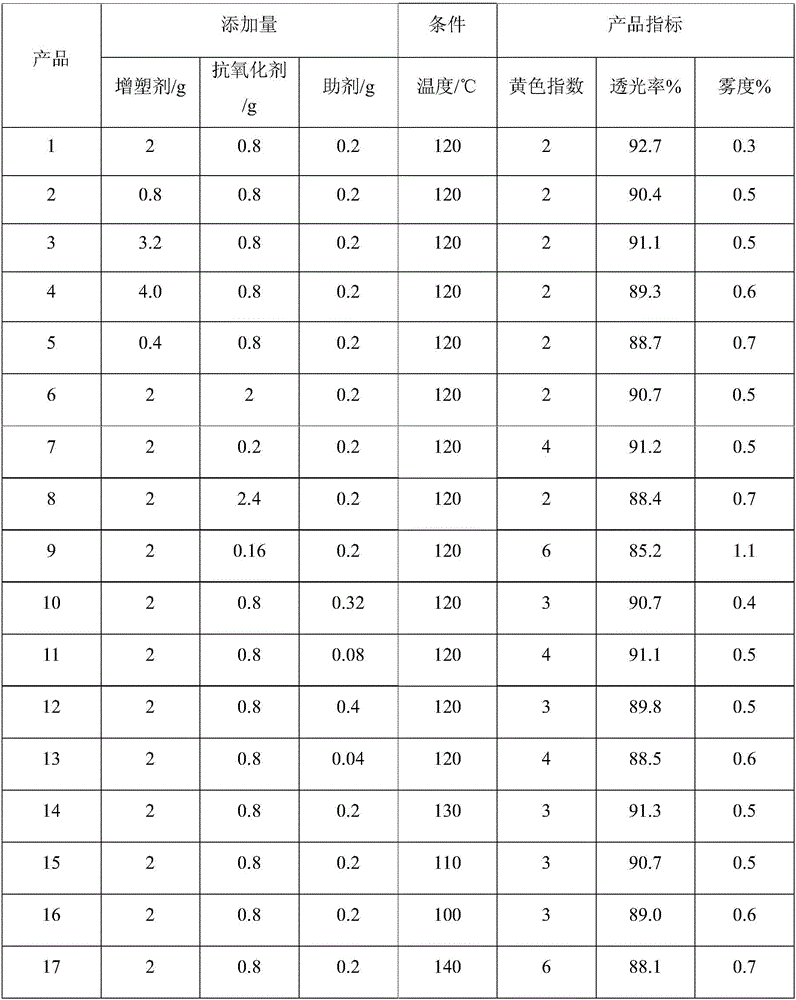

[0044] 400g of PVB resin corresponding to Product 1 in Example 1 is mixed with plasticizer triethylene glycol diisocaprylate 2g, antioxidant DLTP 0.8g, auxiliary agent sodium dodecyl aryl sulfonate 0.2g, and the obtained The mixed solution is evenly fed into the extruder by the feeding system, heated to 120°C by the extruder, uniformly plasticized and turned into a molten state, and then flows out from the die lip after being filtered, cooled and shaped, and formed into a 0.76mm PVB film.

[0045] Other conditions remain unchanged, change the quality of plasticizer, antioxidant and auxiliary agent, or change heating temperature, make PVB film by the above-mentioned same method.

[0046] The properties of the obtained PVB film under each condition are shown in Table 2.

[0047] The performance of gained PVB film under each condition of table 2

[0048]

[0049] From Table 2, it can be concluded that the ultra-white PVB film obtained by the present invention is at plasticizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com