Stain-resistant and anti-coking special-shaped pipe

A special-shaped tube and anti-coking technology, applied in the direction of tubes, rigid tubes, tubes/pipe joints/fittings, etc., can solve problems such as unsatisfactory effects, achieve weakening or inhibiting coking tendency, increase heat transfer effect, and increase turbulence degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

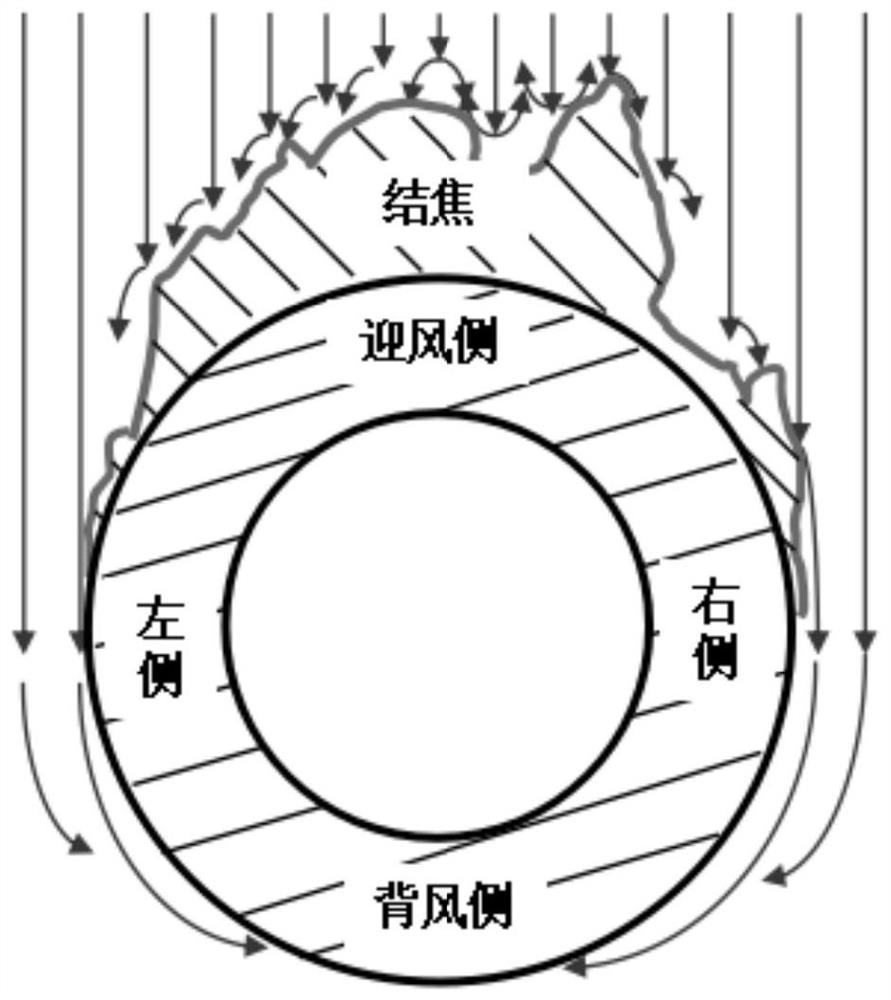

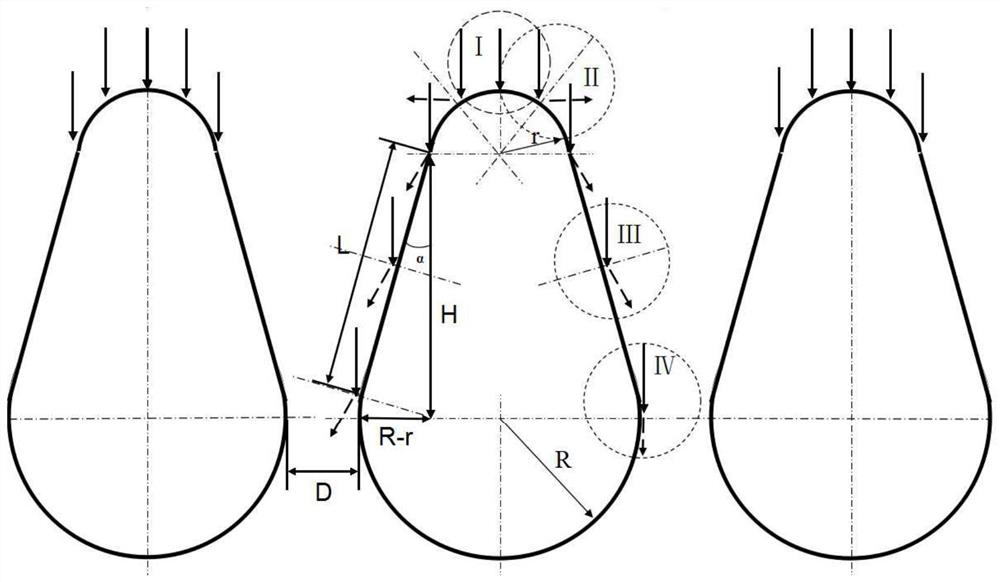

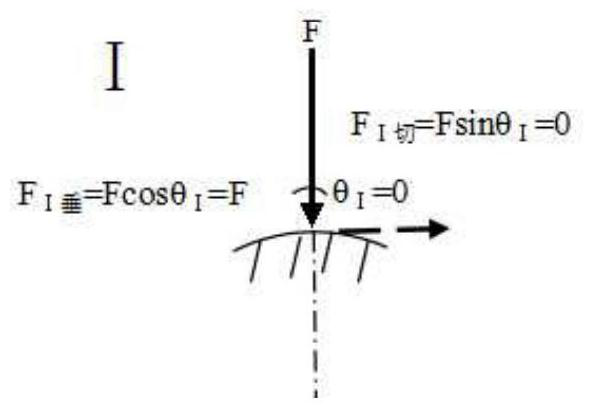

[0047] combine figure 2 , the round tube of the special-shaped tube is changed to a drop-shaped tube, and the radii of the small end and the large end of the drop-shaped tube are r and R respectively. When the R-r difference is constant, the larger the distance H between the large and small ends, the smaller the angle α, and the longer the length L of the circumferential pipe wall connecting the large and small ends, that is, L tends to H. Such as Figure 3c As shown in (Ⅲ), the airflow incident angle θ at position Ⅲ of the connection area between the large and small ends Ⅲ The larger the pressure F acting vertically on the pipe wall Ⅲ垂 =Fcosθ Ⅲ The smaller the is, the smaller the adhesion generated by the impact is, and the cutting force F generated by the impact along the pipe wall surface Ⅲ切 =Fsinθ Ⅲ is larger, then use the ratio of the two γ=F Ⅲ切 / F Ⅲ垂 =tgθ Ⅲ As a measure of the airflow knife effect coefficient, the larger the γ, the more obvious the effect of ant...

Embodiment 2

[0049] Special-shaped pipes include conical-semicircular combined pipes, when such as figure 2 When the small end of the shown dropper becomes a point and that is when r=0, then it evolves into Figure 4 The windward surfaces shown are all conical, that is, the state of position III, which is defined as a conical-semicircular combined pipe. The coking tendency on the windward side of the cone is the smallest, that is, Figure 4 Tube types shown are most favorable for stain and coking resistance. When H / R is larger, that is, α is smaller, θ Ⅲ The bigger it is, the wind knife effect coefficient γ=F Ⅲ切 / F Ⅲ垂 =tgθ Ⅲ The larger it is, the better the effect of inhibiting coking.

Embodiment 3

[0051] Special-shaped tubes include elliptical tubes, and the schematic diagram of the anti-staining and anti-coking mechanism of elliptical tubes is as follows Figure 6 shown. The short and long radii of an elliptical tube are r and R, respectively. When R-r is larger, the transition from position Ⅰ to position Ⅳ, that is, from the long axis to the short axis, is smoother, such as Figure 7b As shown in (II), the airflow incident angle θ at position II Ⅱ The larger the pressure F acting vertically on the pipe wall Ⅱ垂 =Fcosθ Ⅱ The smaller the is, the smaller the adhesion generated by the impact is, and the cutting force F generated by the impact along the pipe wall surface Ⅱ切 =Fsinθ Ⅱ The larger it is, the wind knife effect coefficient γ=F Ⅱ切 / F Ⅱ垂 =tgθ Ⅱ The larger it is, the more obvious the anti-staining and anti-coking. Compared with the round tube, the incidence angle of the elliptical tube becomes larger, so the adhesion force generated by the impact becomes sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com