Detonation tube structure of a rotary pulse detonation engine

A technology of pulse detonation and detonation tube, which is applied to mechanical equipment, intermittent injection devices, etc., can solve the problems of shortening the detonation tube length of detonation engines, high oil and gas mixing degree, and low fuel utilization rate, etc. The effect of full combustion, reduced weight, increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described now in conjunction with accompanying drawing:

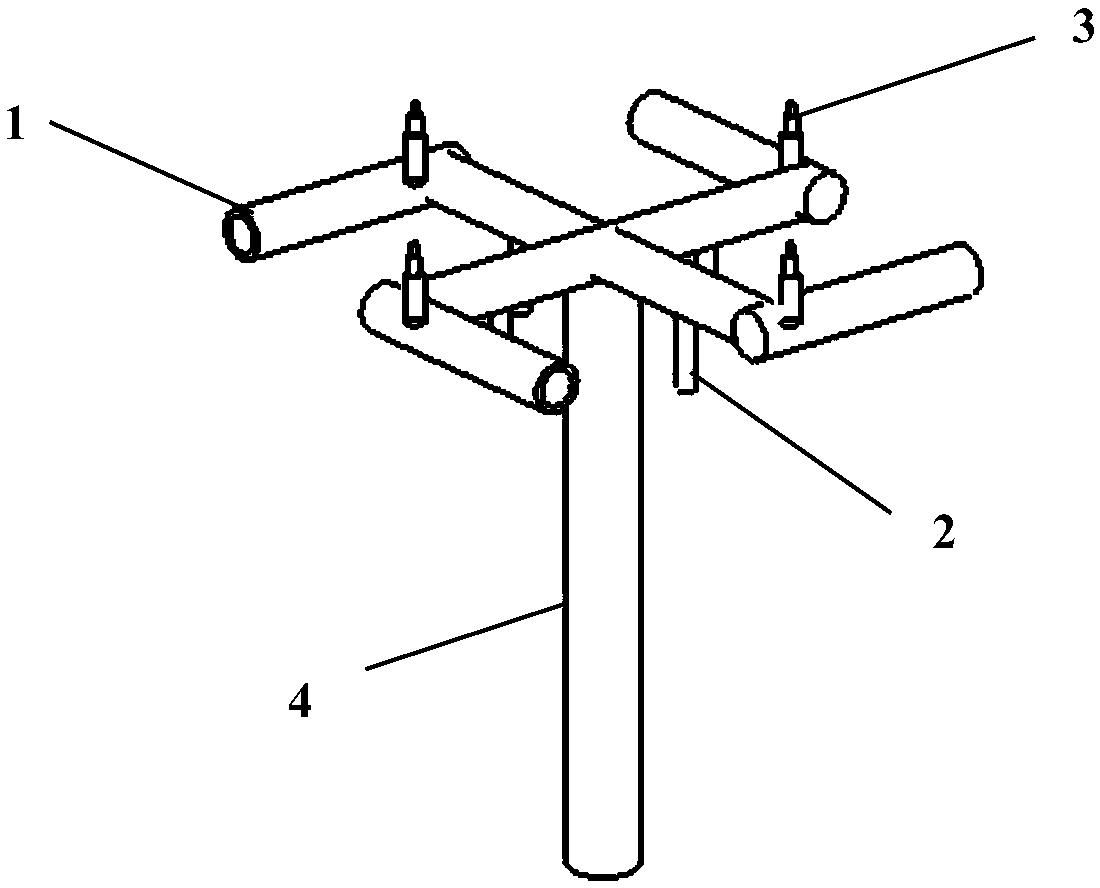

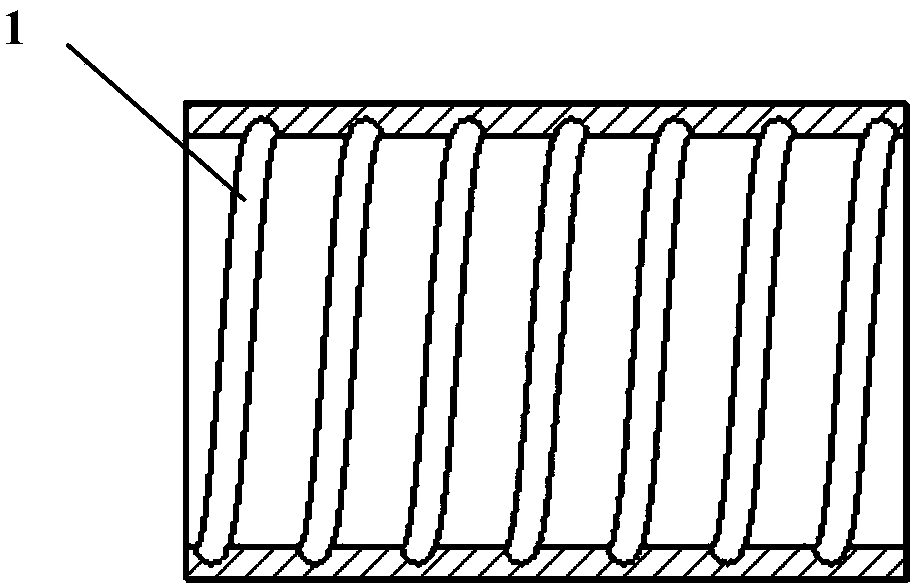

[0017] combine figure 1 and figure 2 , The invention provides a novel detonation tube structural plate of a rotary pulse detonation engine capable of stably outputting shaft work. figure 2 It is a structural schematic diagram of the spiral groove on the inner wall of the detonation tube of the rotary pulse detonation engine.

[0018] figure 1 It is a structural schematic diagram of a rotary detonation tube. The detonation tube of a rotary air-breathing pulse detonation engine includes 1-detonation tube, 2-fuel injection tube, 3-spark plug and 4-power output shaft (intake tube). The 1-detonation tube is distributed in a swastika structure, and there are 4 1-detonation tubes, the length of which is the same depending on the design. In addition, there is a straight tube structure at the entrance of the 1-detonation tube for air supply. 2-The fuel injection pipe is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com