Screw-type air compressor with external air intake and dust filtering functions

An air compressor and dust filtration technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of affecting the service life of air compressors, insufficient air volume, high price and high dust filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

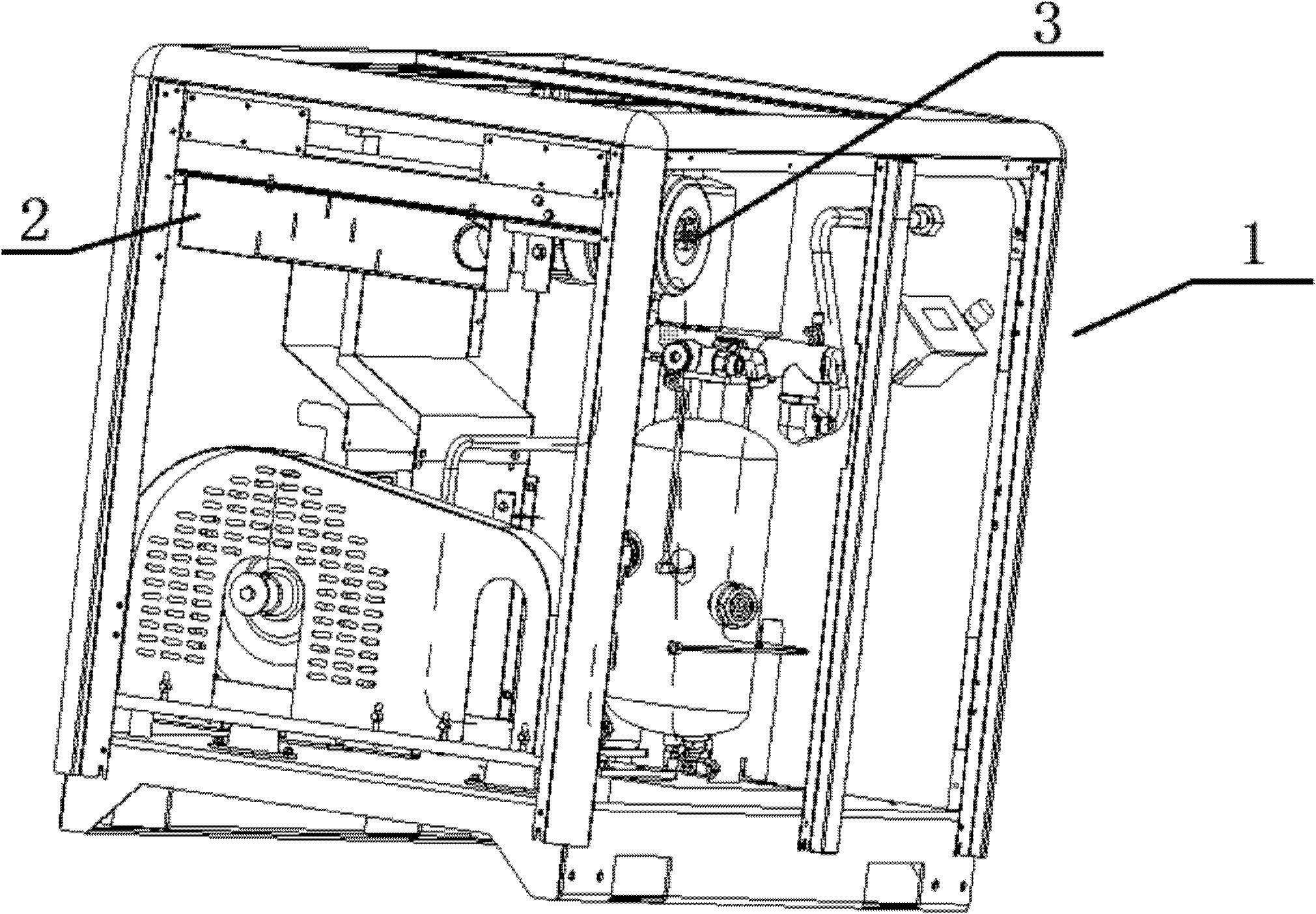

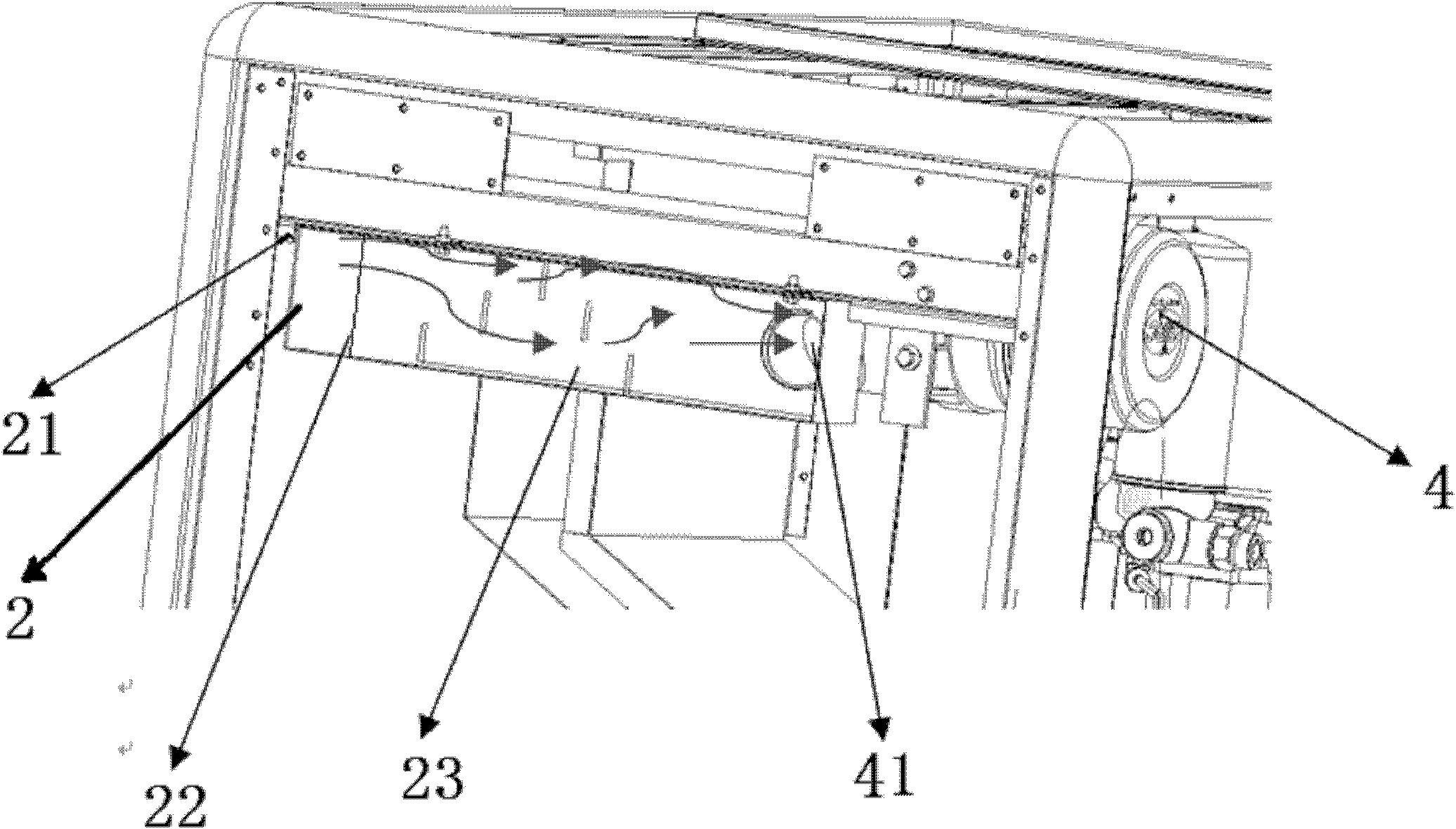

[0019] Such as figure 1 , figure 2 and image 3 as shown, figure 1 It is a schematic diagram of the overall structure of the compressor body 1. The compressor body 1 includes an air intake system. The air intake system includes an independent air intake channel 2. The air intake channel 2 is composed of a rectangular box. The air intake channel box and The internal heat source of the compressor is separated, the beginning of the air intake channel 2 is an air inlet 21, the air inlet 21 is opened on the door panel 3 of the compressor, and the air inlet 21 is provided with an air inlet filter 211, the air inlet filter 211 is a new 3M material, which can play the role of electrostatic dust removal.

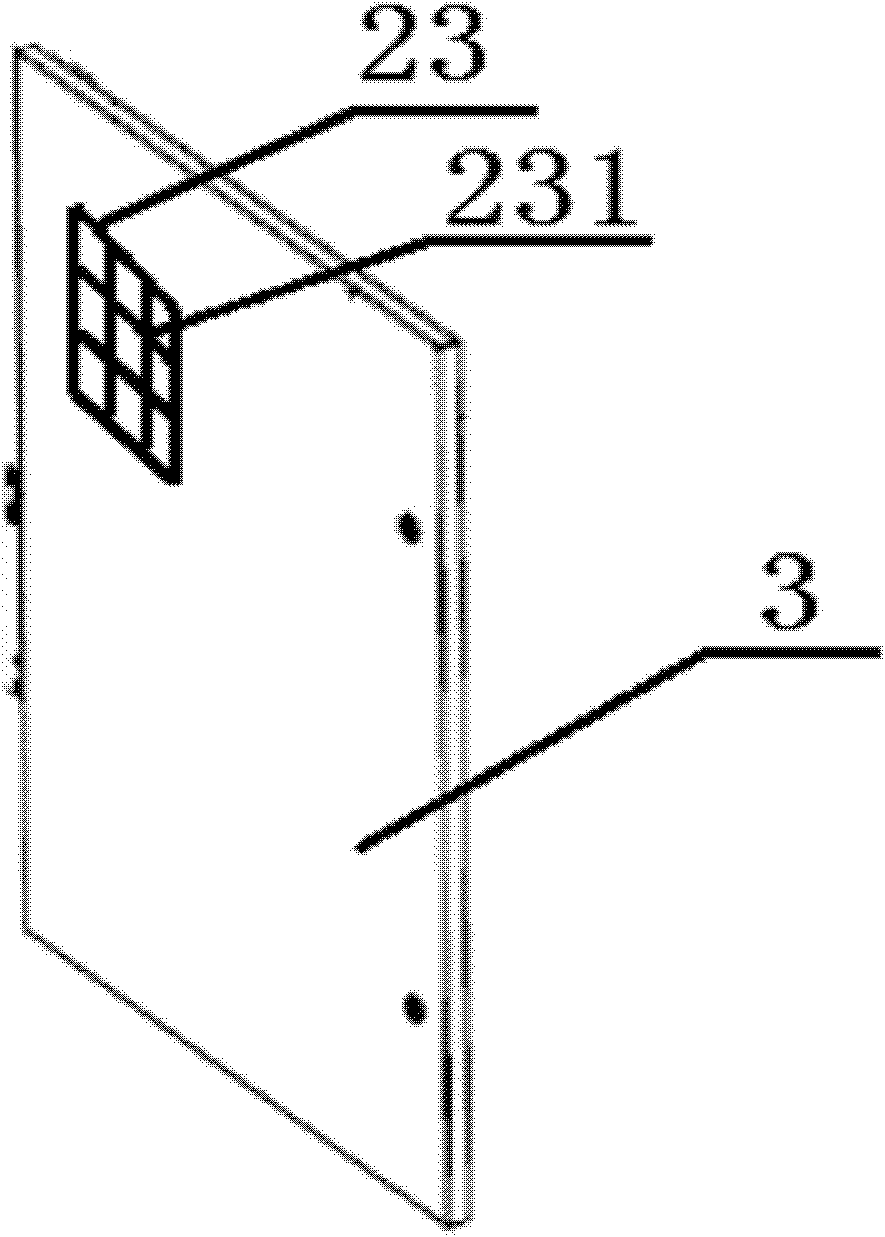

[0020] The rear of the air inlet 21 is provided with a silencer box 22 and a partition 23 in turn. There are three partitions 23. The surfaces of the three partitions are respectively provided with sound-absorbing foam 231. The partition 23 can absorb the noise from the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com