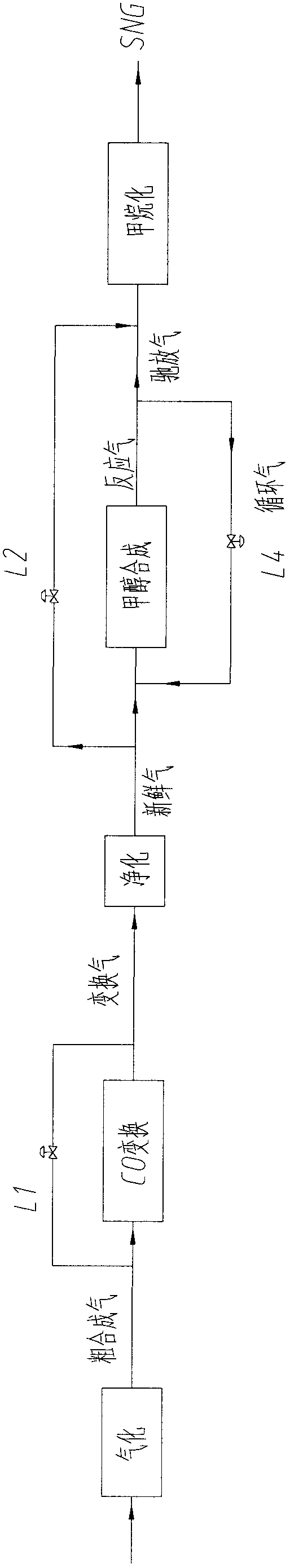

Synthesized methanol and synthesized methane co-production method and equipment

A technology for synthesizing methanol and methane, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems such as easy surge of cycle compression equipment, load can not be greatly adjusted, energy waste, etc., to reduce load , reduce investment and production costs, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 can calculate the hydrogen-carbon ratio of fresh gas by the mole fraction of the output of synthetic methanol and methane

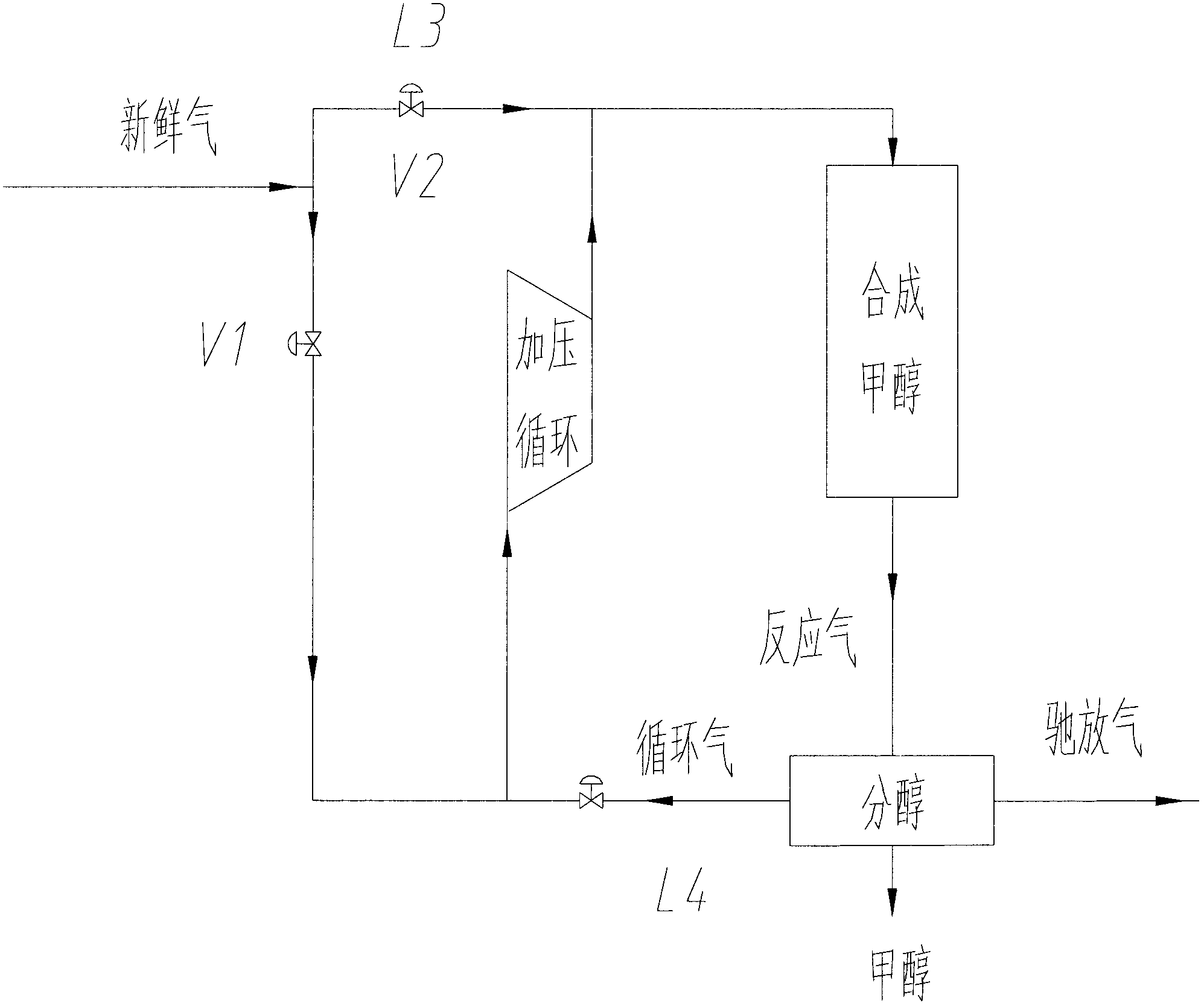

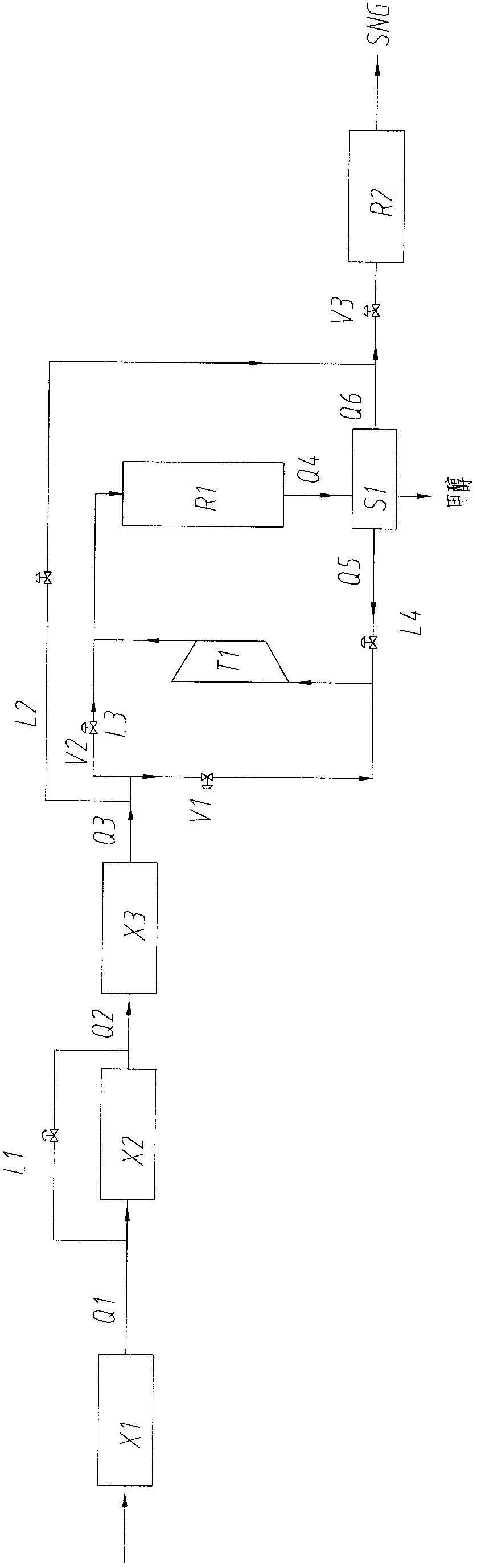

[0048] use as image 3 The device for synthesizing methanol and synthesizing methane as shown includes a gasification device X1, a CO conversion device X2, a purification device X3, a methanol synthesis device and a methanation device R2 connected in sequence, and the CO conversion device X2 is connected in parallel with a conversion Bypass L1, the methanol synthesis device includes a compression cycle machine T1, a methanol synthesis reactor R1 and a methanol separator S1, and the compression cycle machine T1 is sequentially connected with the methanol synthesis reactor R1 and the methanol separator S1, and the The compression cycle machine T1 is connected in parallel with an equal pressure bypass L3, the outlet of the recycle gas of the methanol separator S1 is provided with a circulation pipeline L4 connected to the inlet of the com...

Embodiment 2

[0063] Example 2 Regulating natural gas production by adjusting CO conversion rate and methanol production

[0064] Utilize the device described in Example 1 to implement the artificial natural gas production process, the raw material is coal gas, and the natural gas production is regulated by adjusting the CO conversion rate and methanol output. Tables 2 and 3 are respectively the same gas volume and composition using no peak regulation and peak regulation. material balance sheet.

[0065] Table 2 Material list without peak regulation

[0066]

crude synthesis gas

change gas

methanation gas

SNG

CH 4 Original

11

11

11

11

96.0 (total CH 4 count)

H 2

31

39.25

39.25

0

CO

20

11.75

11.75

0

CO 2

37

45.25

1

0

N 2

1

1

1

1

4.0

[0067] CH 3 Oh

...

Embodiment 3

[0076] Embodiment 3 regulates the output ratio of methanol and methanation by synthesis pressure

[0077] use as image 3 In the device shown, part of the crude synthesis gas Q1 undergoes a partial shift reaction through the CO shift device, and the other part passes through the shift bypass L1 and mixes with the gas exiting the CO shift device X2 to form shift gas Q2, and then enters the purification device X3 and is removed by washing with low-temperature methanol Sulfur and most of the CO 2 , fresh gas volume and composition are shown in Table 4:

[0078] Table 4 The amount and composition of fresh gas entering methanol synthesis and methanol purge gas entering methanation

[0079]

[0080] Control the methanol synthesis pressure at 4.0, 3.5, and 2.5 MPa to synthesize methanol respectively. The resulting methanol yield and hydrogen-carbon ratio of demethanated gas are shown in Table 5 below:

[0081] Table 5 Calculated data of the same raw material purified gas under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com