Micro bubble generator and diffusion crushing technology-based ship micro bubble generating device

A micro-bubble generator and micro-bubble generation technology, applied in the direction of ship hull, ship construction, hull design, etc., can solve the problems of large jet resistance, high energy consumption of micro-bubbles, small bubble output, etc., to overcome high manufacturing cost, design The effect of simple processing and low installation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

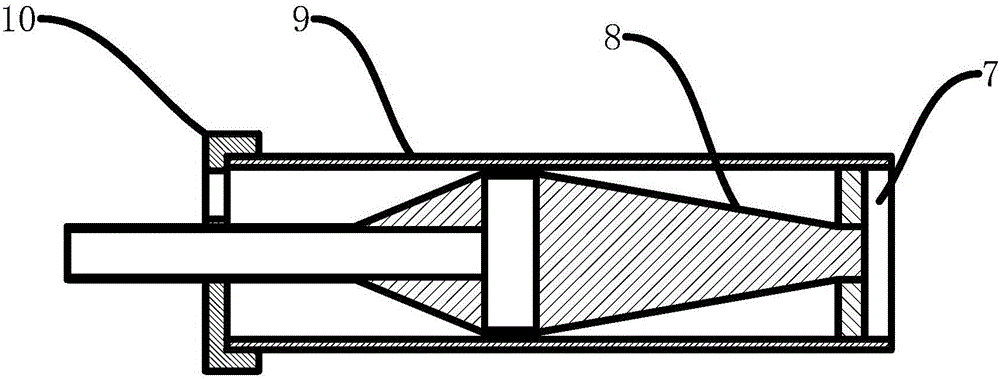

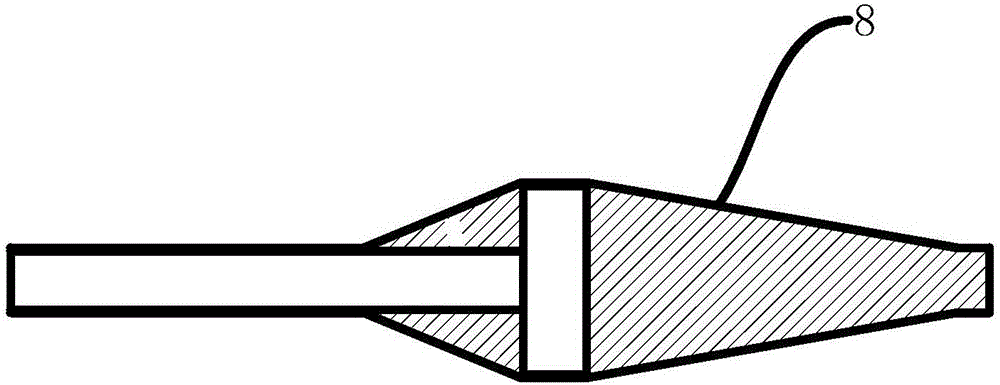

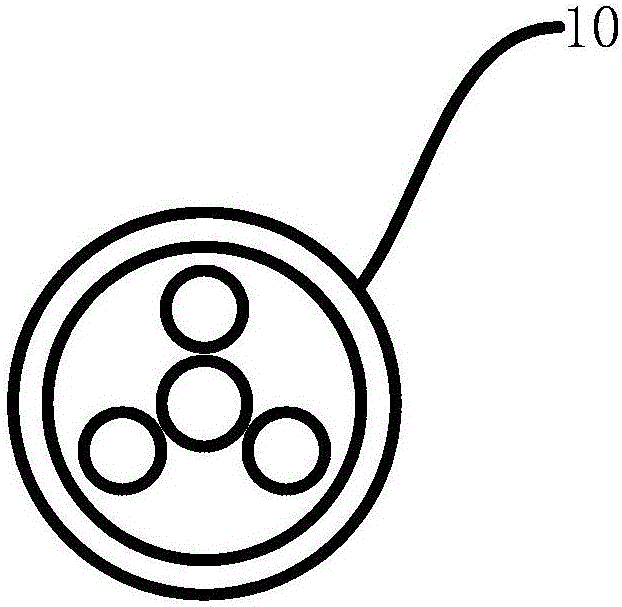

[0026] Such as figure 1 with 2 As shown, a microbubble generator includes a bubble nozzle 7, a fluid core 8, a housing 9 and an end cover 10; the housing 9 or the end cover 10 is provided with a water inlet; the fluid core 8 is in the middle of the diameter It is a hollow shuttle-shaped structure with large and small ends. Its body is provided with an air inlet, and an exhaust hole is opened around the largest cross-sectional diameter. The fluid core 8 is placed in the housing 9 of the bubble generator, so that the cross-sectional area of the space in the housing 9 except the fluid core 8 gradually decreases from both ends to the middle; one end of the housing 9 is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com